Price 600000.0 आईएनआर/ Unit

Specification

- शोर का स्तर

- डीबी

- फ़्रिक्वेंसी

- हर्ट्ज (एचजेड)

- फेज

- 3

- गर्म करने की विधि

- Gas

- मटेरियल

- टाइप करें

- क्षमता

- किलो/घंटा

- कम्प्यूटरीकृत

- ऑटोमेटिक

- कंट्रोल सिस्टम

- वोल्टेज

- वोल्ट (v)

- पावर

- हार्सपावर (HP)

- फ़ीचर

- , , , ,

- वारंटी

- 1 Year warranty against manufacturing defect.

Trade Information

- Minimum Order Quantity

- 1 Unit

- डिलीवरी का समय

- हफ़्ता

About

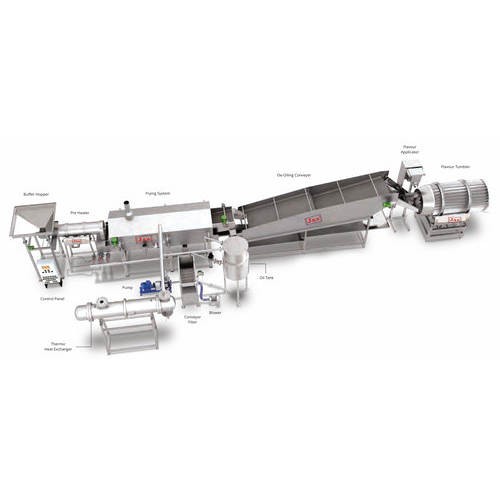

The Jas Enterprise Popcorn Making Line is a fully integrated, high-efficiency system designed for commercial and industrial popcorn production. Built with advanced engineering and food-grade materials, this automated line delivers consistent output, superior hygiene, and maximum productivity.

At the core of the system is the Jas brand Gas and Electric Operated Popcorn Making Machine, featuring a pneumatic lifting mechanism for effortless and safe unloading after each batch. The machine ensures uniform heating, high popping efficiency, and reduced un-popped kernels.

The popped corn is transferred through a Metered Hopper, which regulates product flow for smooth and controlled feeding. From there, the product moves onto a Conveyor Unit connected to the Rotary Drum Screening Machine. This specially designed drum effectively separates uncooked kernels, corn bran, fines, and small residues, ensuring only clean, fully popped corn advances to the next stage.

For final seasoning, the screened popcorn enters the Flavoring Tumbler, which uniformly coats each kernel with the desired flavourwhether salty, cheesy, caramel, butter, or any specialty blend. Its gentle tumbling action ensures consistent taste and an attractive finish.

Ideal for snack processing units, large-scale popcorn manufacturers, cinemas, and packaged food brands, this complete line enhances efficiency, reduces manual labour, and ensures a premium, ready-to-pack product.

High-Efficiency, Eco-Friendly Operation

The Industrial Popcorn Making Line prioritizes sustainable manufacturing. Its gas heating method ensures quick production with lower energy consumption while the advanced engineering provides a high efficiency rate. Operating at 85 db, it maintains a low noise level, creating a workplace-friendly environment. Built from durable stainless steel, the line demands minimal maintenance and promotes eco-friendly operation.

Versatile, Large-Scale Production

Capable of processing up to 100 kg of popcorn per hour, this machine meets the high demands of industrial settings. Suitable for manufacturers, distributors, exporters, and traders, it streamlines the popcorn-making process. The compact design allows seamless integration into various production facilities without taking up excess space.

FAQ's of Industrial Popcorn Making Line:

Q: How does the Industrial Popcorn Making Line operate?

A: The machine runs on a 15 HP motor with a gas heating mechanism, using a fully automatic system controlled manually. Place the raw kernels and oil into the stainless steel chamber, set the parameters, and the system manages popping and output efficiently.Q: What is the main benefit of using this popcorn making line in an industrial setting?

A: It offers high efficiency with a capacity of 100 kg/hr, low noise, and reduced energy consumption. Its compact structure is ideal for optimizing workspace, while the stainless steel build ensures long-lasting, hygienic operation.Q: When is maintenance required for this equipment?

A: Regular maintenance is recommended according to the user manual, but the robust stainless steel construction means it requires less frequent upkeep. The 1-year warranty covers any manufacturing defects that may occur.Q: Where can this popcorn machine be installed?

A: Designed for use in industrial environments, it is suitable for food factories, processing plants, and commercial kitchens across India. Its compact structure allows for flexible placement in various production spaces.Q: What process does the machine use to produce popcorn?

A: Using a manual control system, the machine heats the kernels with gas, and the automatic popping mechanism ensures consistent and uniform production. The popped corn is then efficiently discharged for further processing or packaging.Q: What types of users benefit most from this machine?

A: Manufacturers, wholesalers, distributors, exporters, retailers, and traders in the food processing industry, especially those looking to scale up production while minimizing operational costs and environmental impact, will find it particularly advantageous.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in स्नैक्स मेकिंग मशीन Category

हाथ से संचालित पकोड़ा बनाने की मशीन

न्यूनतम आदेश मात्रा : 1

मूल्य की इकाई : यूनिट/यूनिट

माप की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

ऑटोमेटिक : नहीं

वारंटी : सभी टूटफूट वाले हिस्सों को छोड़कर, हमारी साइट पर विनिर्माण दोषों के खिलाफ एक वर्ष। विद्युत हिस्से इस वारंटी में शामिल नहीं हैं

कॉर्न स्नैक्स मशीन

न्यूनतम आदेश मात्रा : 1

मूल्य की इकाई : यूनिट/यूनिट

माप की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

ऑटोमेटिक : हाँ

वारंटी : हमारी साइट पर विनिर्माण दोष के खिलाफ 1 वर्ष

फ्राइड बीन्स, दाल और दाल स्नैक्स प्रोडक्शन लाइन

न्यूनतम आदेश मात्रा : 1

मूल्य की इकाई : यूनिट/यूनिट

माप की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

ऑटोमेटिक : हाँ

वारंटी : हमारी साइट पर विनिर्माण दोष के खिलाफ 1 वर्ष

भाकरवाड़ी मशीन

न्यूनतम आदेश मात्रा : 1

मूल्य की इकाई : यूनिट/यूनिट

माप की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

ऑटोमेटिक : हाँ

वारंटी : सभी टूटफूट वाले हिस्सों को छोड़कर, हमारी साइट पर विनिर्माण दोषों के खिलाफ एक वर्ष।

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें