Price 40000 आईएनआर/ Unit

Specification

- विशेषताएँ

- Durable, Easy to Operate

- फेज

- Single Phase

- गर्म करने की विधि

- No Heat

- स्पीड मोड

- ऑटोमेशन ग्रेड

- Automatic

- शोर का स्तर

- Low

- फीडिंग सिस्टम

- Belt Conveyor

- परिचालन तापमान

- Room Temperature

- फ़्रिक्वेंसी

- 50 Hz

- पावर सोर्स

- Electric

- फंक्शन टाइप

- मशीन का प्रकार

- Semi-Automatic

- प्रॉडक्ट टाइप

- Mathiya Making Machine

- सामान्य उपयोग

- Mathiya/Khakhra/Papad Making

- मटेरियल

- टाइप करें

- क्षमता

- 4000-5000 टुकड़ाs/hr

- वजन (किग्रा)

- 400 kg

- उत्पाद का आकार

- कम्प्यूटरीकृत

- ऑटोमेटिक

- कंट्रोल सिस्टम

- इंस्टालेशन टाइप

- वोल्टेज

- 220-240 V

- पावर

- 2 HP

- आयाम (एल* डब्ल्यू* एच)

- 2000 x 800 x 1300 mm

- कच्चा माल

- फ़ीचर

- रंग

- Surface Treatment

- Polished

- Maintenance Requirement

- Minimal

- Production Efficiency

- Up to 95%

- Mobility

- Fitted with Wheels

- Motor Type

- Copper Winding

- Suitable For

- Small and Medium Scale Industries

- Output Thickness Range

- 0.5 to 3 mm

- Safety Features

- Emergency Stop Switch

Trade Information

- Minimum Order Quantity

- 1 Unit

- मुख्य निर्यात बाजार

- , , , , , , , ,

- प्रमाणपत्र

- ISO 9001

About

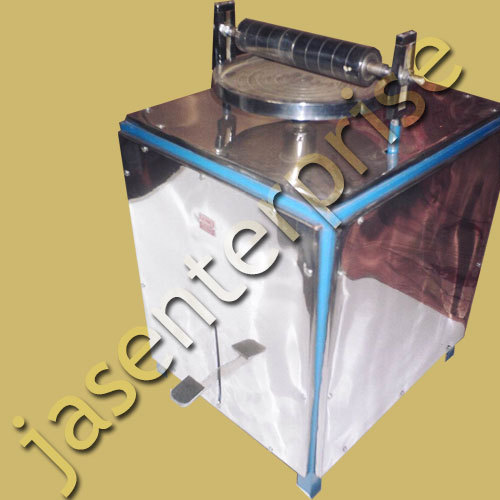

Introducing the Jas Brand Mathiya Making Machine a revolutionary appliance designed to bring efficiency and precision to your Mathiya production process. Crafted with precision engineering, this machine is tailored to meet the demands of commercial kitchens and food processing units, providing a reliable solution for crafting perfect Mathiya with ease.

Key Features:

-

Efficient Dough Preparation: The Jas Mathiya Making Machine excels in preparing the perfect Mathiya dough. Its advanced mixing and kneading mechanism ensure consistency in texture, resulting in uniform and delicious Mathiya every time.

-

Customizable Thickness and Size: Tailor your Mathiya to perfection with adjustable thickness and size settings. The machine allows you to customize the dimensions of your Mathiya, accommodating various preferences and culinary requirements.

-

High Production Capacity: Boost your production output with the machines high capacity. Whether youre catering to a bustling restaurant or a large-scale food processing unit, the Jas Mathiya Making Machine is designed to meet the demands of high-volume production.

-

Precise Cutting Mechanism: Achieve uniform Mathiya pieces effortlessly with the machines precise cutting mechanism. The cutting blades are engineered for accuracy, ensuring that each Mathiya is consistent in size and shape.

-

User-Friendly Operation: Designed with ease of use in mind, the machine features a user-friendly interface. Intuitive controls and straightforward operation make it easy for operators to produce high-quality Mathiya with minimal training.

-

Durable and Hygienic Construction: The Mathiya Making Machine is built with durability and hygiene in focus. Crafted from high-quality materials, it ensures longevity even in demanding commercial environments. The machines design also facilitates easy cleaning, maintaining the highest standards of food safety.

-

Versatility in Application: Beyond Mathiya, this machine is versatile enough to handle various dough-based products, providing flexibility in your production line. Explore different culinary creations with the Jas Mathiya Making Machine.

-

Compact Design for Space Efficiency: Despite its high capacity, the machine boasts a compact design to optimize space utilization in your kitchen or food processing facility. It seamlessly integrates into your production line without sacrificing valuable space.

Upgrade your Mathiya production process with the Jas Brand Mathiya Making Machine where precision meets efficiency. Elevate the quality of your Mathiya, reduce labor-intensive tasks, and streamline your production with a machine thats engineered for excellence in every aspect of Mathiya preparation.

Precision and Efficiency

The Mathiya Making Machine stands out for its impressive efficiency, capable of achieving production rates up to 95%. Thickness adjustments between 0.5 and 3 mm provide full control over product output, enabling consistent, high-quality results. This reliability helps businesses meet their production targets efficiently and effectively.

Robust Design and Easy Mobility

Manufactured from polished stainless steel, this machine is built for durability and longevity. It is also designed with mobility in mind, featuring sturdy wheels that make it effortless to reposition within the workspace. Its sleek appearance and rugged build complement its practical functions.

User-Oriented Automation

Equipped with a PLC control system, the Mathiya Making Machine streamlines the production process while maintaining ease of use. Its automatic operation and minimal maintenance requirements allow operators to focus on quality and productivity without concern for downtime or complicated upkeep.

FAQs of Mathiya Making Machine:

Q: How does the Mathiya Making Machine ensure consistent product thickness?

A: The machine features a precise mechanism that allows operators to adjust output thickness between 0.5 mm and 3 mm, ensuring each piece is produced to the desired specifications consistently.Q: What benefits do small and medium scale industries gain from using this machine?

A: Small and medium enterprises benefit from high production rates, low maintenance, and ease of operation. Its compact, movable design and automation minimize labor costs while maintaining product quality and output efficiency.Q: When is maintenance required for this machine?

A: Due to its minimal maintenance requirement and robust design, routine checks are sufficient. Preventive maintenance such as cleaning and occasional inspections for wear are recommended to keep the machine in optimal condition.Q: Where is the Mathiya Making Machine best installed within a facility?

A: This free-standing machine is designed for versatility, easily fitting into any production area. Thanks to its fitted wheels, it can be conveniently relocated as needed within small or medium industrial setups.Q: What is the process of making Mathiya with this machine?

A: Operators place flour as raw material into the feeding system. The machine then mixes, forms, and presses the dough into round shapes, using adjustable pressure and output settings; no heating is involved in the process.Q: How is the machine operated and what safety features does it offer?

A: Operation is straightforward, controlled via a PLC system, with an emergency stop switch included as a safety feature. Adjustable speed modes and a low-noise environment enhance both usability and operator comfort.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in पापाड मेकिंग मशीन Category

एक्सट्रूडर के साथ आटा गूंधने वाला

न्यूनतम आदेश मात्रा : 1

मूल्य की इकाई : यूनिट/यूनिट

क्षमता : 10 से 25 किलो/घंटा

माप की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

ऑटोमेटिक : हाँ

एक्सट्रूडर के साथ एसएस आटा केनेडर

न्यूनतम आदेश मात्रा : 1

मूल्य की इकाई : यूनिट/यूनिट

माप की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

ऑटोमेटिक : हाँ

चोलाफली बनाने की मशीन

न्यूनतम आदेश मात्रा : 1

मूल्य की इकाई : यूनिट/यूनिट

क्षमता : 10 से 500 तक किलो/घंटा

माप की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

ऑटोमेटिक : हाँ

पापड़ प्रेस- पापड़ रोलिंग मशीन

न्यूनतम आदेश मात्रा : 1

मूल्य की इकाई : टुकड़ा/टुकड़े

क्षमता : 040 किलो/घंटा

माप की इकाई : टुकड़ा/टुकड़े

मूल्य या मूल्य सीमा : आईएनआर

ऑटोमेटिक : हाँ

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें