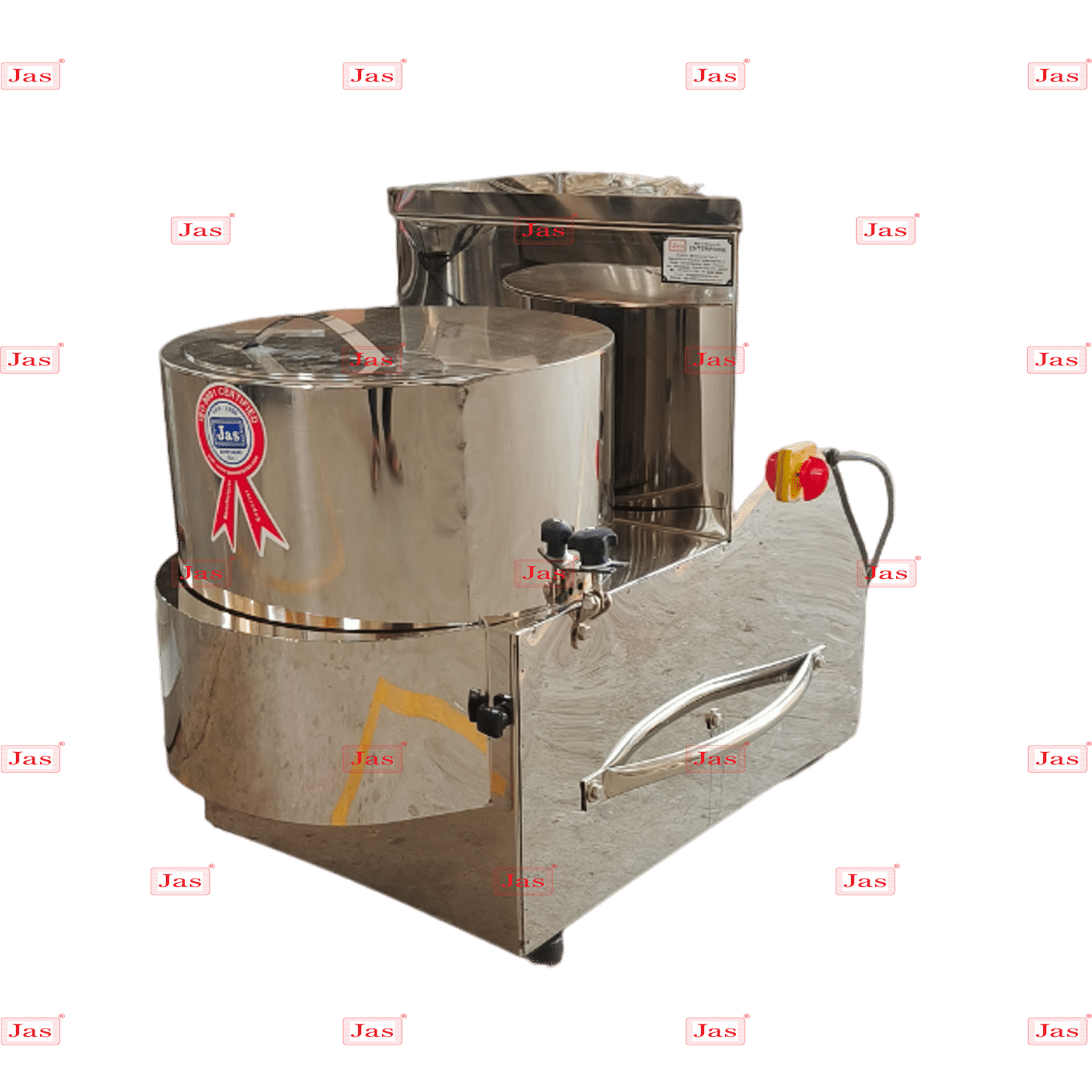

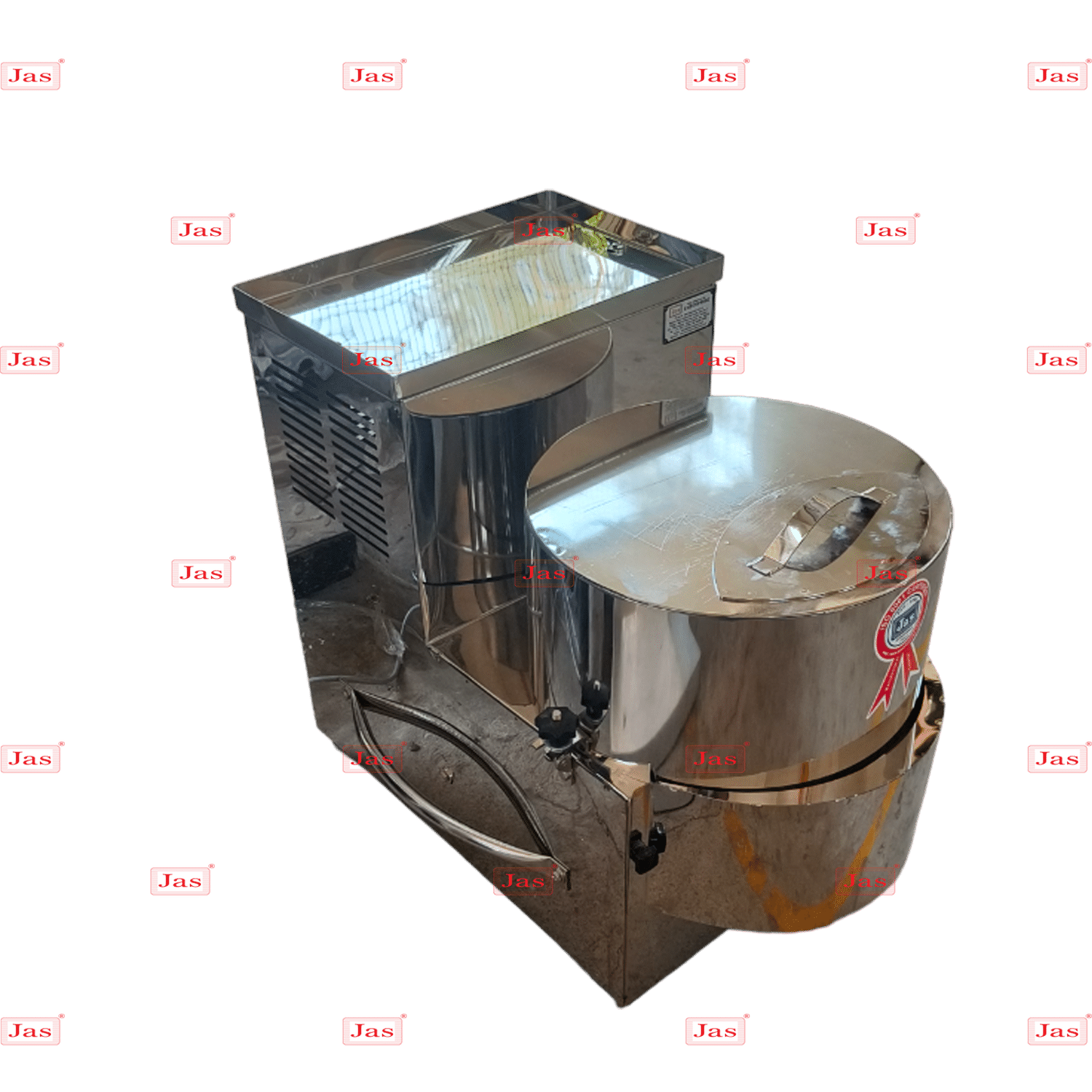

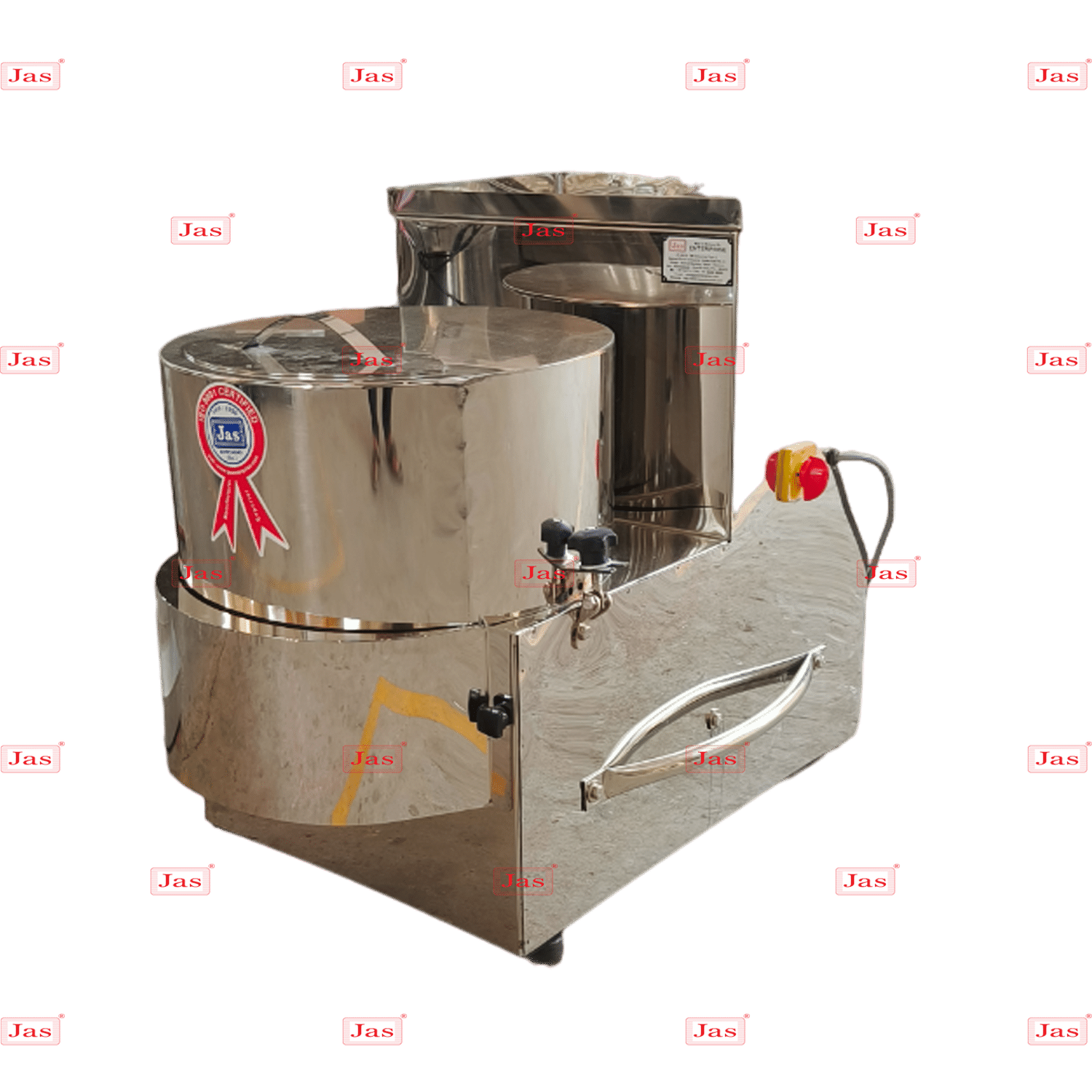

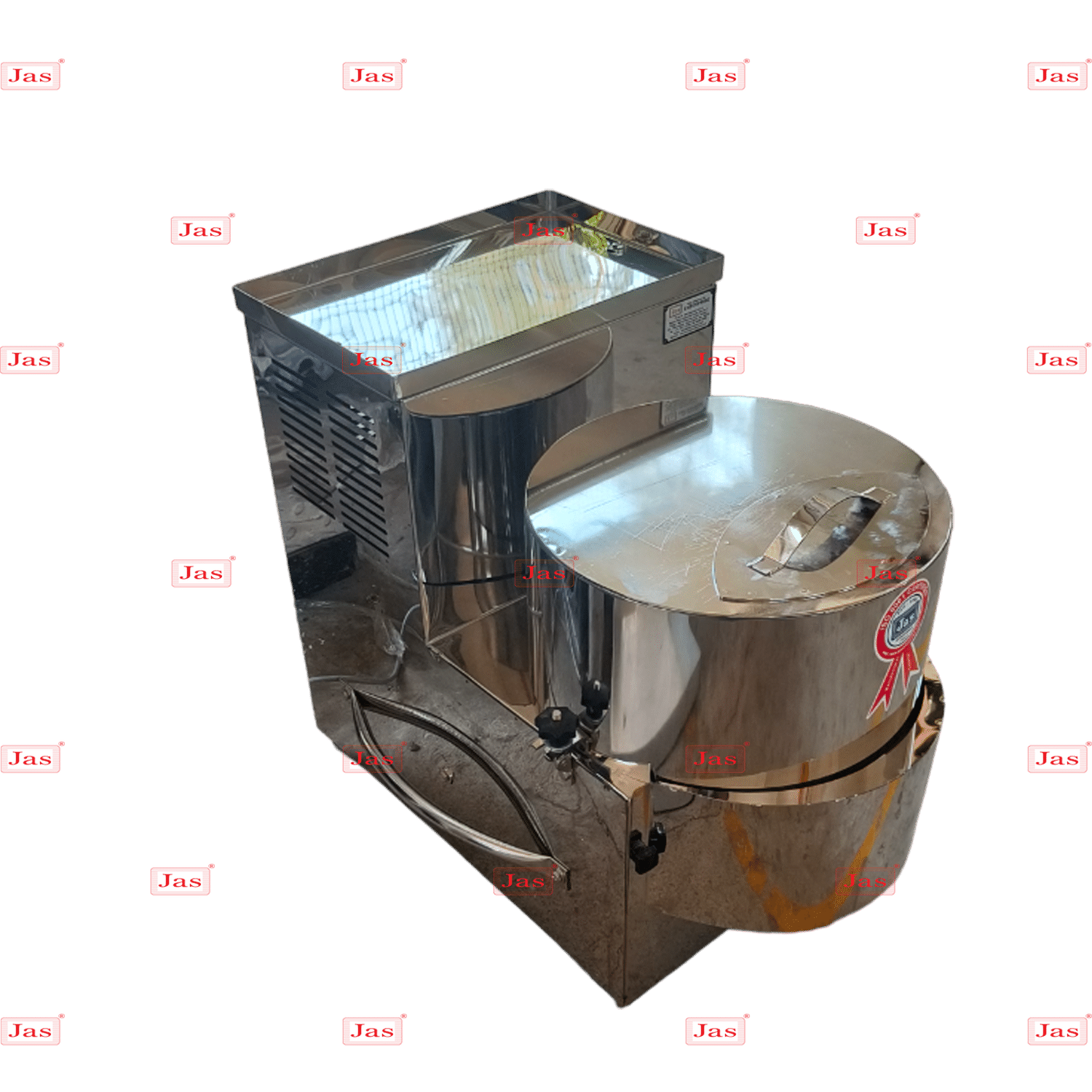

Price 29000 आईएनआर/ Unit

MOQ : 1 Unit

Specification

- क्षमता

- किलो/घंटा

- ऑटोमेटिक

- वोल्टेज

- वोल्ट (v)

- फ़ीचर

- , , , ,

Trade Information

- Minimum Order Quantity

- 1 Unit

- भुगतान की शर्तें

- , , , ,

- मुख्य निर्यात बाजार

- , , , , , , , ,

- मुख्य घरेलू बाज़ार

- , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , ,

- प्रमाणपत्र

- ISO

About

Types of Potato Cutting Machines:

-

Manual Potato Cutters:

- French Fry Cutters: Typically use a lever mechanism to push potatoes through a grid, cutting them into sticks. Ideal for making uniform fries.

- Mandolins: Adjustable blades can slice potatoes into different thicknesses or julienne them. They require manual effort but are versatile for different cuts.

-

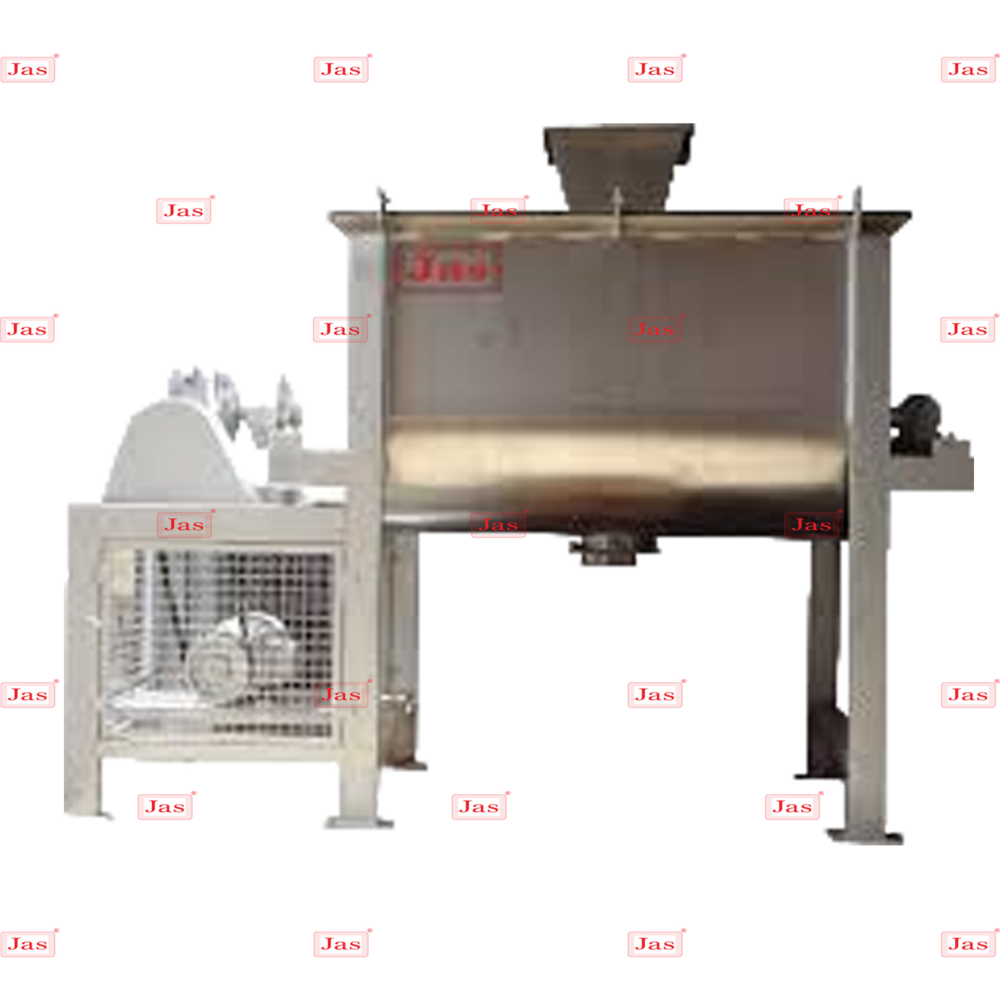

Electric Potato Cutters:

- Food Processors: Often come with various attachments, including slicing and dicing blades. They are efficient for bulk processing.

- Dedicated Potato Slicers: These machines are specifically designed to handle potatoes and can process large quantities quickly.

Key Features to Consider:

- Material: Look for durable materials like stainless steel for blades and strong plastics for the frame.

- Ease of Cleaning: Removable parts and dishwasher-safe components make cleaning easier.

- Size and Capacity: Choose based on how many potatoes you need to cut at a time.

- Safety Features: Look for machines with non-slip bases and safety guards to prevent accidents.

Eco-Friendly and Energy Efficient

Engineered with sustainability in mind, the Potato Cutting Machine consumes less energy compared to conventional equipment. Its efficient design helps lower electricity costs and promotes an environmentally responsible approach to food processing, making it a smart choice for forward-thinking businesses.

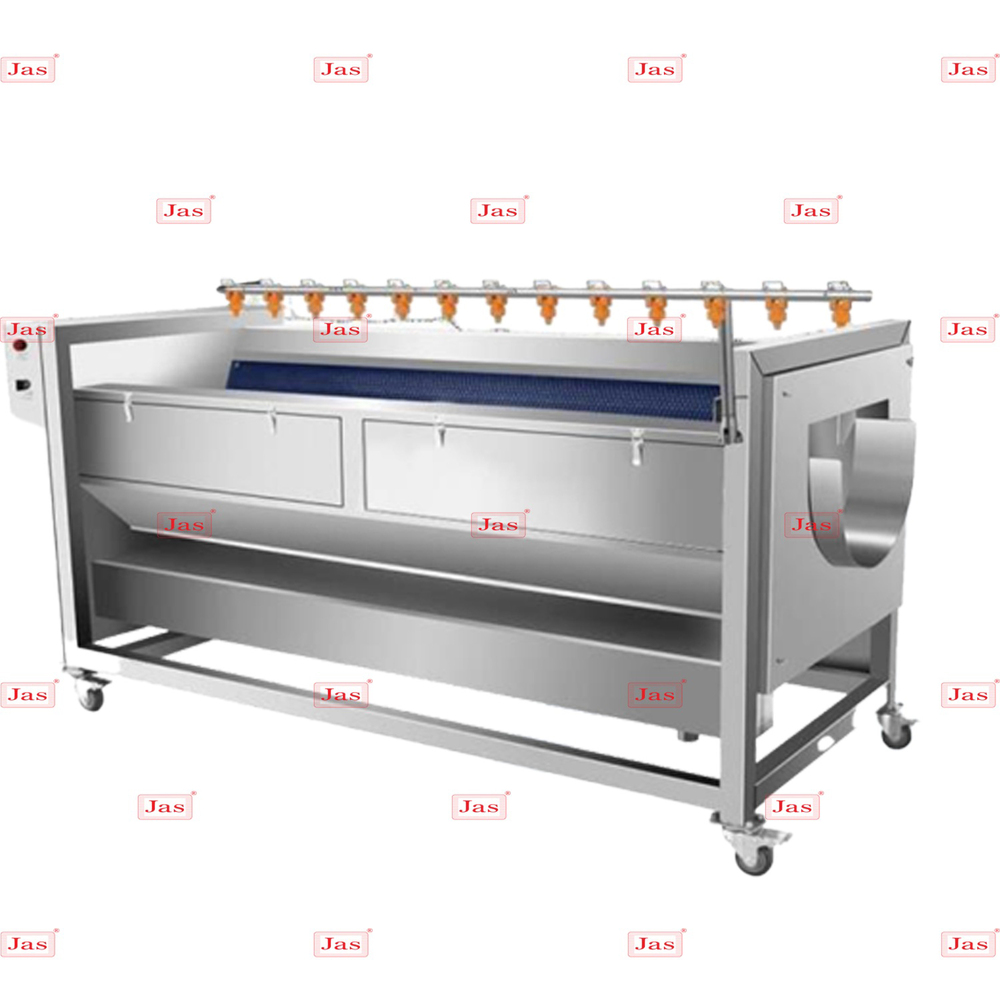

Compact Design, High Capacity

Despite its space-saving compact structure, the machine delivers impressive cutting capacity from 10 up to 1000 kg per hour. This adaptability ensures it fits seamlessly into operations of any scale, from small kitchens to large processing plants, providing consistent and reliable performance throughout India.

Quiet Operation, Maximum Output

Manufactured for smooth, quiet operation, this machine dramatically reduces workplace noise levels. Its advanced mechanisms guarantee high cutting efficiency, making processing faster without the distraction of loud machinery, thereby enhancing the work environment for operators.

FAQs of Potato Cutting Machine:

Q: How does the Potato Cutting Machine maintain high efficiency with such low energy consumption?

A: The machine utilizes advanced motors and precision engineering to optimize performance. This means it processes large quantities of potatoes swiftly while minimizing power use, achieving high throughput without raising operational costs.Q: What are the environmental benefits of using this potato cutting machine?

A: Its eco-friendly design reduces energy consumption and operates with minimal noise, contributing to a lower carbon footprint. This makes it suitable for businesses aiming to implement sustainable and responsible practices.Q: When is the best time to use this potato cutting machine in food processing operations?

A: The machine is ideal for continuous use during peak production periods or daily processing routines, thanks to its durable build, automatic operation, and broad capacity range. It streamlines workflows in both high- and low-volume settings.Q: Where can this machine be installed or used effectively?

A: Thanks to its compact structure, the machine can be efficiently installed in restaurants, food manufacturing plants, hotels, catering services, and any commercial kitchen or processing unit across India, regardless of space constraints.Q: Can you explain the process of operating the automatic potato cutting machine?

A: Simply connect the machine to a 230 or 440-volt power supply, load the cleaned potatoes, and select the desired cutting mode. The machine automatically processes the potatoes quickly and evenly, requiring minimal manual intervention.Q: What benefits can suppliers and traders expect from distributing this machine?

A: Suppliers and traders benefit from offering a high-demand product that combines efficiency, sustainability, and user-friendliness. Its versatility and compliance with modern environmental standards make it attractive across multiple market segments in India.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in खाद्य प्रसंस्करण तंत्र Category

हरी और पत्तेदार सब्जी काटने की मशीन

मूल्य या मूल्य सीमा : आईएनआर

फ़ीचर : उच्च दक्षता, ऊर्जा की कम खपत, पर्यावरण के अनुकूल, लो नॉइस, कॉम्पैक्ट स्ट्रक्चर

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : यूनिट/यूनिट

वोल्टेज : 110 से 440 वोल्ट (v)

न्यूनतम आदेश मात्रा : 1

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें