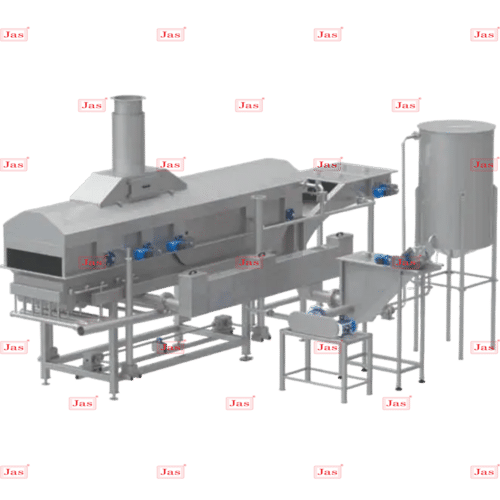

Industrial Continuous Potato Chips Fryer

Price 1750000 INR/ Unit

Industrial Continuous Potato Chips Fryer Specification

- Capacity

- 500 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Industrial Continuous Potato Chips Fryer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Industrial Continuous Potato Chips Fryer

-

Continuous Operation: These fryers are designed to operate continuously, allowing for a consistent output of fried potato chips without interruptions in the production line.

-

Conveyor Belt System: Potato chips are fed into the fryer via a conveyor belt system that moves them through the fryer at a controlled pace. This ensures uniform frying and prevents overcrowding or uneven cooking.

-

Oil Heating and Circulation: The fryer maintains a large quantity of cooking oil at a precise temperature using heating elements and circulation systems. This temperature control is crucial for achieving the desired texture and flavor of the potato chips.

-

Oil Filtration and Management: Industrial fryers often include systems for filtering and managing the cooking oil. This helps to extend the oils lifespan, maintain product quality, and reduce operating costs.

-

Adjustable Speed and Temperature: Operators can typically adjust the speed of the conveyor belt and the temperature of the oil to accommodate different types of potato chips and production requirements.

-

Safety Features: These fryers incorporate various safety features such as automatic shut-off mechanisms, temperature sensors, and guards to protect workers and prevent accidents.

-

Cleaning and Maintenance: Regular cleaning and maintenance are essential to ensure hygiene and prolong the fryers lifespan. Many industrial fryers are designed with easy-to-clean components and access points.

-

Capacity and Output: The capacity of these fryers can vary significantly depending on the model and manufacturer, ranging from hundreds to thousands of kilograms of potato chips per hour.

-

Energy Efficiency: Modern industrial fryers often incorporate energy-efficient technologies to reduce operational costs and environmental impact.

-

Control Systems: Advanced control systems may be included to monitor and adjust parameters such as oil temperature, frying time, and conveyor speed automatically.

High-Efficiency Frying for Large-Scale Production

Engineered for industrial needs, the continuous potato chips fryer delivers consistent and rapid output, processing up to 500 kg of potato chips per hour. Its automatic controls and compact design help optimize factory workflow while maintaining top product quality.

Eco-Friendly and Cost-Saving Operation

This fryer is built with advanced technology that ensures low noise and lower energy consumption, reducing operational costs and environmental impact. Its energy-efficient mechanisms make it a smart investment for sustainable food manufacturing.

FAQs of Industrial Continuous Potato Chips Fryer:

Q: How does the automatic operation improve the frying process?

A: The automatic system controls temperature, conveyor speed, and oil levels, ensuring each batch is evenly cooked. This results in consistent product quality while reducing manual labor and error, which enhances safety and productivity.Q: What benefits does the fryer offer over traditional batch fryers?

A: Unlike traditional fryers, the continuous fryer provides higher throughputup to 500 kg/hralong with lower noise and improved energy efficiency. It also features a compact structure, saving valuable floor space and reducing maintenance requirements.Q: When is this fryer suitable for installation in a production facility?

A: This fryer is ideal for mid to large food processing plants aiming to increase productivity without compromising quality. Its especially beneficial when seeking to scale up potato chip production with automated and energy-saving technology.Q: Where can this industrial fryer be used in India?

A: Manufacturers, exporters, wholesalers, distributors, retailers, and suppliers across India can install this fryer in food processing factories, commercial kitchens, and snack production units. It aligns with Indian industrial voltage requirements of 230/440V.Q: What is the basic process for operating the fryer?

A: Simply load prepared potato slices onto the conveyor, set the desired temperature and speed, then activate the automatic controls. The fryer continuously processes the potatoes, producing evenly fried chips with minimal oversight.Q: How does its eco-friendly feature benefit manufacturers?

A: Its energy-saving design lowers electricity consumption, which reduces operating costs and carbon footprint. Manufacturers gain a competitive edge by offering products made through more sustainable, environmentally conscious methods.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Potato Chips Making Machines Category

French Fry Making Machines

Price 18000 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : 200 to 250 Kg/hr

Voltage : 110440 Volt (v)

Automatic : Yes

Semi Automatic Potato Chip Line

Price Range 1500000.00 - 3500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 100 TO 500 Kg/hr

Voltage : 110440 Volt (v)

Automatic : Yes

Wafer Machine

Price Range 35000.00 - 165000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 300 to 1000 Kg/hr

Automatic : Yes

Semi Automatic Chips Making Machine

Price 25000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 3001000 Kg/hr

Voltage : 230/440 Volt (v)

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free