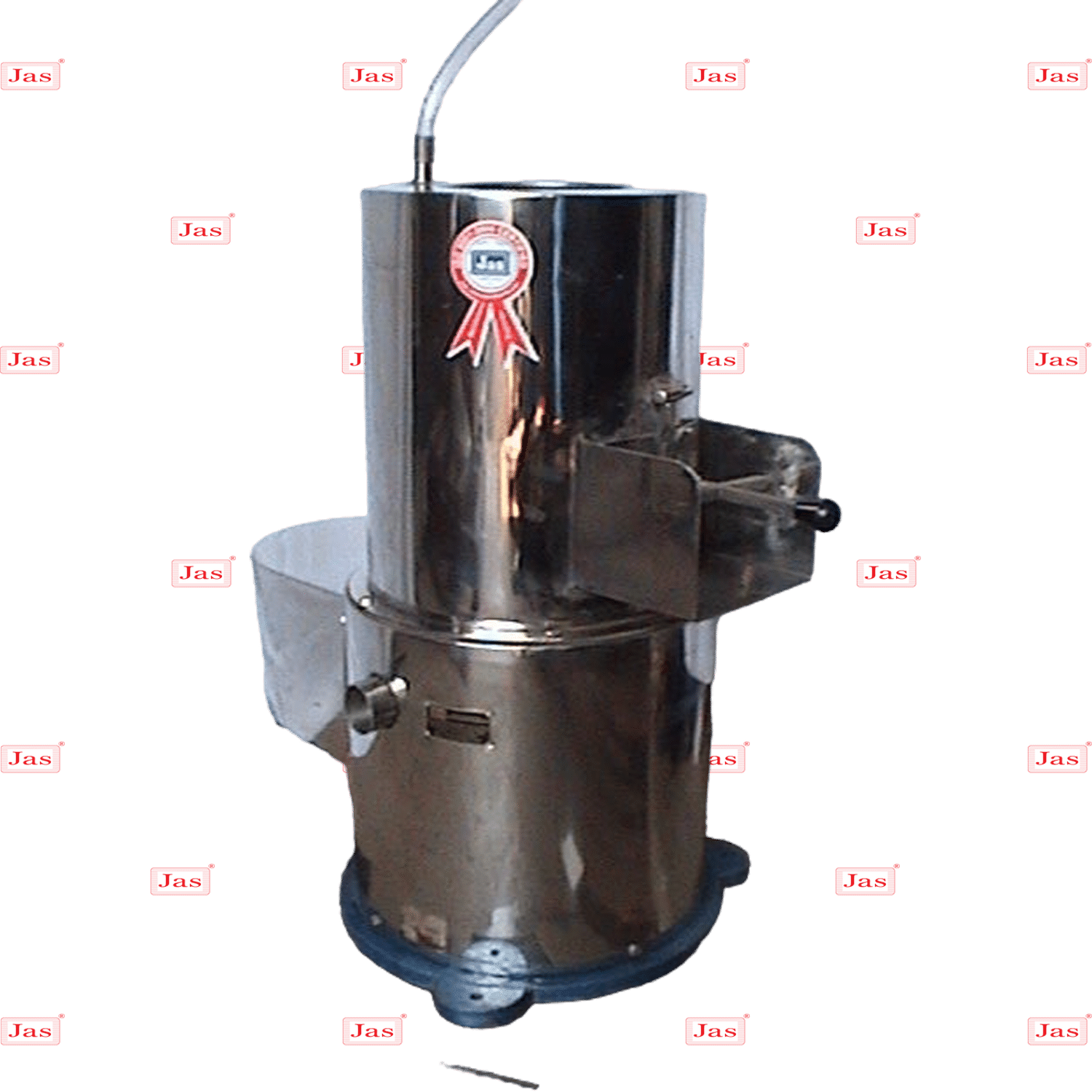

Industrial Potato Chips Making Machine

Price 25000 INR/ Unit

Industrial Potato Chips Making Machine Specification

- Capacity

- 300-1000 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Industrial Potato Chips Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Industrial Potato Chips Making Machine

Key Components:

-

Feeding System: Automates the process of loading potatoes into the machine. It often includes conveyors or hoppers.

-

Peeling Unit: Removes the potato skins. This can be a mechanical peeler or a steam peeler.

-

Slicing Unit: Cuts potatoes into uniform slices. This could be a rotary slicer, knife cutter, or a blade system.

-

Washing Unit: Cleans the potato slices to remove excess starch and any impurities.

-

Blanching Unit: Briefly cooks the potato slices in hot water or steam to stop enzymatic browning and improve texture.

-

Frying Unit: Cooks the potato slices in hot oil. Industrial machines often have continuous fryers for high throughput.

-

Seasoning System: Applies flavorings and seasonings to the chips after frying. This might include tumblers or spray systems.

-

Cooling System: Lowers the temperature of the chips after frying to make them crispy.

-

Packaging System: Packages the finished chips into bags or other containers. This can include weighing and sealing systems.

Efficient and Sustainable Production

Our Industrial Potato Chips Making Machine is engineered to combine high efficiency with eco-friendly operation. With advanced automation, it minimizes labor and energy consumption while ensuring a consistent output of potato chips. Its robust construction and compact design make it suitable for both large food processing units and smaller manufacturing setups.

Versatile Applications

Designed for the Indian market, this machine serves distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers. Its wide capacity range and energy-efficient features make it adaptable for different scales of business, catering to the evolving needs of the snack food industry.

FAQs of Industrial Potato Chips Making Machine:

Q: How does the Industrial Potato Chips Making Machine enhance production efficiency?

A: The machine automates most stages of potato chips production, enabling continuous operation with minimal manual intervention. Its high-capacity range and advanced technology result in faster output, reduced processing time, and efficient resource use.Q: What features ensure eco-friendly and low-noise operation?

A: This machine incorporates energy-efficient components and advanced noise reduction technology, significantly lowering power consumption and operating noise. These features help companies maintain an environmentally responsible and worker-friendly production environment.Q: When is it ideal to use this machine in a potato chips processing business?

A: This machine is most beneficial when scaling up production to meet higher market demand. Its robust performance is perfect for both new setups aiming for efficiency and established operations needing enhanced throughput with lower overheads.Q: Where can businesses install the machine for optimal performance?

A: Its compact design allows installation in various factory settings, be it a large food processing unit or a smaller workshop. As long as there is access to a 230/440 Volt power supply, the machine can be easily integrated into existing production lines.Q: What is the operational process of the potato chips making machine?

A: The process involves feeding peeled and sliced potatoes into the machine, where they are automatically washed, fried, seasoned, and conveyed for packing. Each stage is precisely controlled to maintain chips quality and efficiency.Q: How does using this machine benefit distributors and suppliers in India?

A: Distributors and suppliers benefit from the machines high output, reduced production costs, and consistent product quality. Its eco-friendly operation can also help businesses meet regulatory requirements while appealing to environmentally conscious consumers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Potato Chips Making Machines Category

Tapioca Chip Making Machine

Price 25000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Automatic : Yes

Capacity : 3001000 Kg/hr

Potato Peelers

Price Range 15000.00 - 90000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Lower Energy Consumption, High Efficiency, Low Noice, Compact Structure

Automatic : Yes

Capacity : 5 to 50 Kg/hr

Potato Chips Dewatering Machines (Centrifugal Dryers)

Price Range 25000.00 - 130000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Lower Energy Consumption, ECO Friendly, Low Noice, High Efficiency, Compact Structure

Automatic : Yes

Capacity : 7 to 60 Kg/hr

Wafer Machine

Price Range 35000.00 - 165000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Lower Energy Consumption, ECO Friendly, Low Noice, High Efficiency, Compact Structure

Automatic : Yes

Capacity : 300 to 1000 Kg/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free