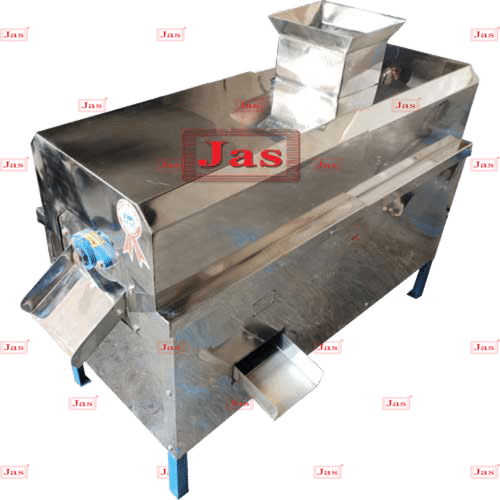

mango Pulping Machine

Price 45000 INR/ Unit

mango Pulping Machine Specification

- Material

- SS

- Capacity

- 50-2000 mango/hr Kg/hr

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Voltage

- 220/440 Volt (v)

- Frequency (MHz)

- 50-60 Hertz (HZ)

- Size

- Standard

- Warranty

- One year against manufacturing defect at our side

mango Pulping Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About mango Pulping Machine

The mango pulping machine typically includes features such as automatic feeding, continuous operation, easy cleaning mechanisms, and low maintenance. Some advanced models are equipped with dual-stage pulping for higher extraction efficiency and can handle both ripe and semi-ripe mangoes.

Available in various capacities ranging from small-scale units for local businesses to industrial-scale machines for large production lines, this machine significantly reduces manual labor and processing time, ensuring consistent quality and higher yield. It can also be adapted to process other fruits like papaya, guava, and tomato with similar characteristics.

Robust Stainless Steel Construction

Engineered from high-quality stainless steel, the mango pulping machine is built to withstand rigorous processing conditions while ensuring hygiene and easy cleaning. This material choice helps the equipment remain rust-resistant and extends its operational lifespan.

Wide Application Range

With a capacity ranging from 50 to 2000 kg per hour, this machine meets the demands of both small businesses and large-scale mango processing plants. Its versatility allows it to cater to varying processing requirements efficiently.

User-Friendly Operation

The semi-automatic design makes this pulping machine easy to operate, requiring minimal technical training. It streamlines mango pulp extraction, reducing manual labor and improving productivity without the need for computerized controls.

FAQ's of mango Pulping Machine:

Q: How does the semi-automatic mango pulping machine operate?

A: The mango pulping machine uses a semi-automatic mechanism that requires manual input to load mangoes, but the pulping process itself is automated. The machine efficiently separates the pulp from the seed and skin, producing consistent results with minimal manual intervention.Q: What is the process for extracting pulp using this machine?

A: To extract pulp, fresh mangoes are loaded into the machine's input section. The internal mechanism crushes and separates the edible pulp from the skin and seed, resulting in a smooth, ready-to-use mango pulp. The stainless steel construction ensures hygiene throughout the process.Q: When is routine maintenance recommended for the machine?

A: Routine maintenance should be performed at least once a month or after every high-volume usage cycle. This includes cleaning the pulp chamber, checking electrical connections, and inspecting moving parts for wear to sustain optimal performance and longevity.Q: Where can this machine be installed for best results?

A: The machine is best installed in food processing units, commercial kitchens, or fruit pulping centers with access to stable electricity (220/440 V) and a standard working environment. Proper ventilation and easy access for cleaning are also recommended.Q: What benefits does the semi-automatic mango pulping machine offer businesses?

A: Businesses benefit from faster pulp extraction, labor cost reduction, and increased output efficiency. Its robust stainless steel build and broad capacity range ensure durability and adaptability to various operational needs, making it an ideal investment for commercial mango processing.Q: How is the machine supported after purchase?

A: The machine comes with a one-year warranty covering manufacturing defects from the supplier's side, ensuring peace of mind and support for business owners through authorized Indian distributors and service partners.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fruit Pulping Machine Category

Fruit Processing Plant

Price 44500 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Voltage : 380V

Capacity : 500 Kg/hr

Frequency (MHz) : 50 Hz

Custard Apple Pulper Machine

Price 32500 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Voltage : 230440 Volt (v)

Capacity : 100500 Kg/hr

Frequency (MHz) : 5060 Hertz (HZ)

Jamun Pulp Making Machine

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Voltage : 110 440 Volt (v)

Capacity : 30 2600 Kg/hr

Tamarind Cover Removal Machine

Price 33000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Voltage : 230/440 Horsepower (HP)

Capacity : 252000 Kg/hr

Frequency (MHz) : 5060 Hertz (HZ)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free