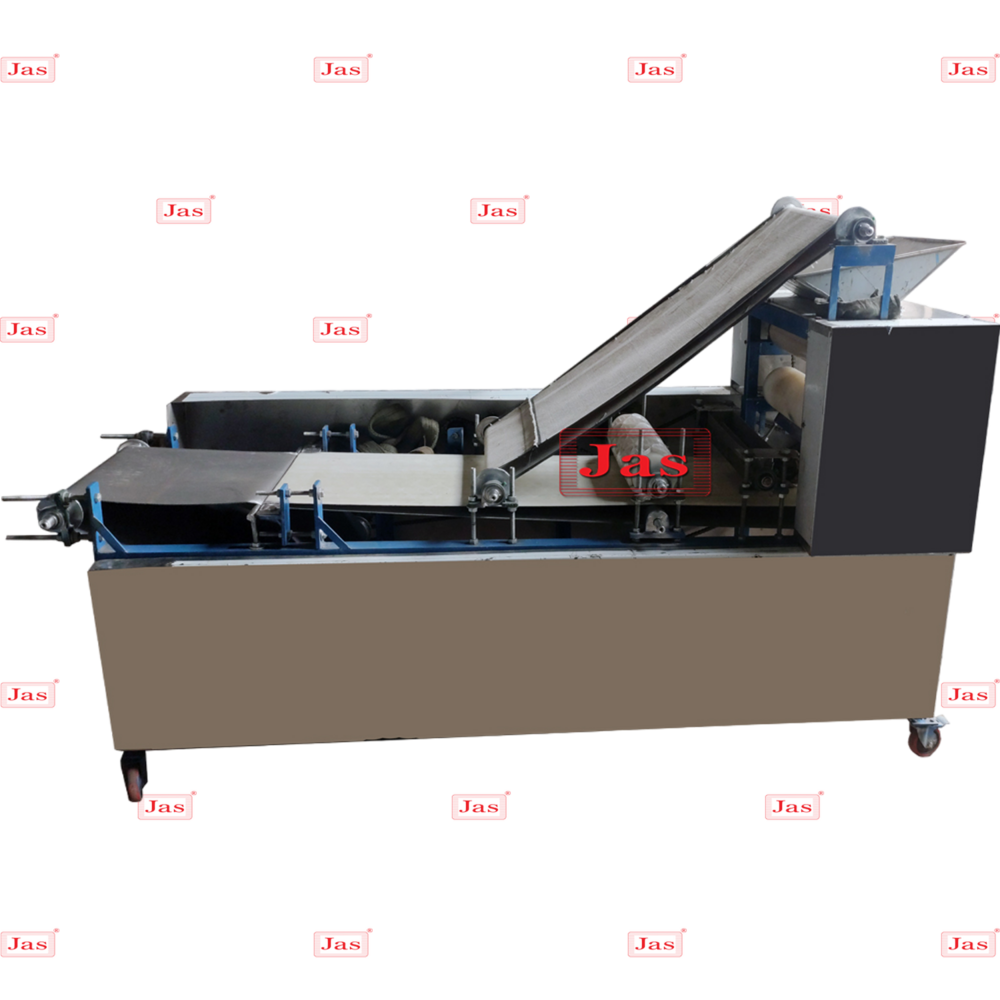

Momos Processing Machine

Price 115000 INR/ Piece

MOQ : 1 Unit

Momos Processing Machine Specification

- Phase

- Single Phase / Three Phase

- Frequency

- 50-60 Hertz (HZ)

- Automation Grade

- Semi Automatic

- Voltage

- 230/440 Volt (v)

- Power

- 0.5-3 Horsepower (HP)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Warranty

- One year against manufacturing defect at our side

Momos Processing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Momos Processing Machine

The Momos Processing Machine is a state-of-the-art piece of equipment engineered for automating the entire process of making momos, a popular steamed dumpling dish widely loved in South Asia, especially in Nepal, India, and Tibet. A versatile solution for both commercial kitchens and large-scale food manufacturing units, this machine takes the labor-intensive process of making momos and simplifies it, improving efficiency, consistency, and hygiene.While traditional methods are labor-intensive and time-consuming, the Momos Processing Machine automates each of these steps, allowing for efficient production, consistency in size and quality, and a significant reduction in preparation time. This machine is particularly useful for large-scale momo production, catering, and businesses like restaurants or food stalls.Versatile and Efficient Momos Production

Designed to streamline the process of making momos, this semi-automatic machine delivers high output with minimal human intervention. Its compact structure and energy-saving features make it ideal for businesses with space and power constraints, while still ensuring consistent and premium quality momos.

Reliability and Peace of Mind

Benefit from a one-year warranty, protecting your investment against manufacturing defects. The machines advanced build quality ensures long-term reliability and requires minimal maintenance, making it a cost-effective choice for any food processing operation.

FAQs of Momos Processing Machine:

Q: How does the Momos Processing Machine operate with different power setups?

A: The machine offers flexibility with both single-phase and three-phase options, operating at 230/440 volts and 50-60 Hz. This allows seamless integration into various food production environments, whether in small kitchens or larger factories.Q: What are the steps involved in processing momos using this machine?

A: To use the machine, simply prepare the dough and filling, then feed them into the designated input sections. The semi-automatic system shapes and seals each momo, with minimal manual handling required, resulting in uniform and hygienic production.Q: When is the ideal time to perform maintenance on the machine?

A: Regular maintenance is recommended every few months or after extended use. This helps maintain high efficiency and extends the machines lifespan. Always refer to the user manual for detailed maintenance schedules and procedures.Q: Where can I purchase or access support for this machine in India?

A: The Momos Processing Machine is available through a network of distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers across India. Support and service are accessible locally, ensuring minimal downtime.Q: What advantages does this machine offer over manual momo making?

A: Compared to manual methods, the semi-automatic machine greatly increases output, reduces physical effort, and provides consistent sizing and sealing. Its eco-friendly design and low energy consumption help lower operating costs.Q: How does the compact design benefit my business space?

A: The compact structure ensures that the machine fits comfortably into smaller workspaces, making it suitable for restaurants or businesses with limited floor area, while maintaining high productivity.Q: What makes this momos processing machine eco-friendly and efficient?

A: The machine incorporates low noise operation, lower energy usage, and materials and components that minimize environmental impact, all while delivering rapid and consistent momo production.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Food Processing Machinery Category

Ribbon Blender

Price 65000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Capacity : 8000 liters Liter/day

Warranty : One year against manufacturing defects at our site

Automatic : Yes

Pan Roaster

Price 70000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Warranty : One year against manufacturing defects at our site

Automatic : Yes

Tray Dryer

Price 155000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Capacity : 75 Kg/hr

Warranty : 1 Year

Automatic : Yes

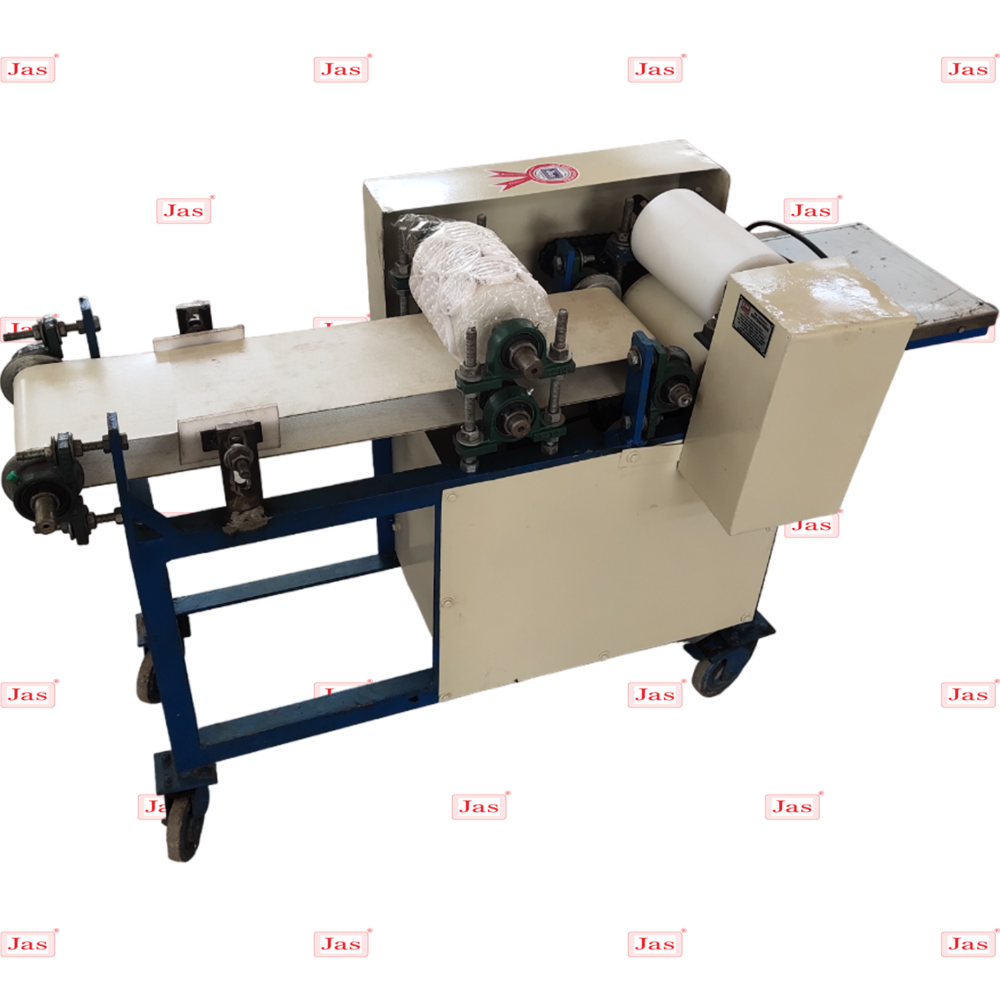

Semi Automatice Momo Dough Sheet Cutting Machine

Price 40000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230 Volt (v)

Capacity : 3002000 Pcs/hr

Warranty : One year against manufacturing defect at our side

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS