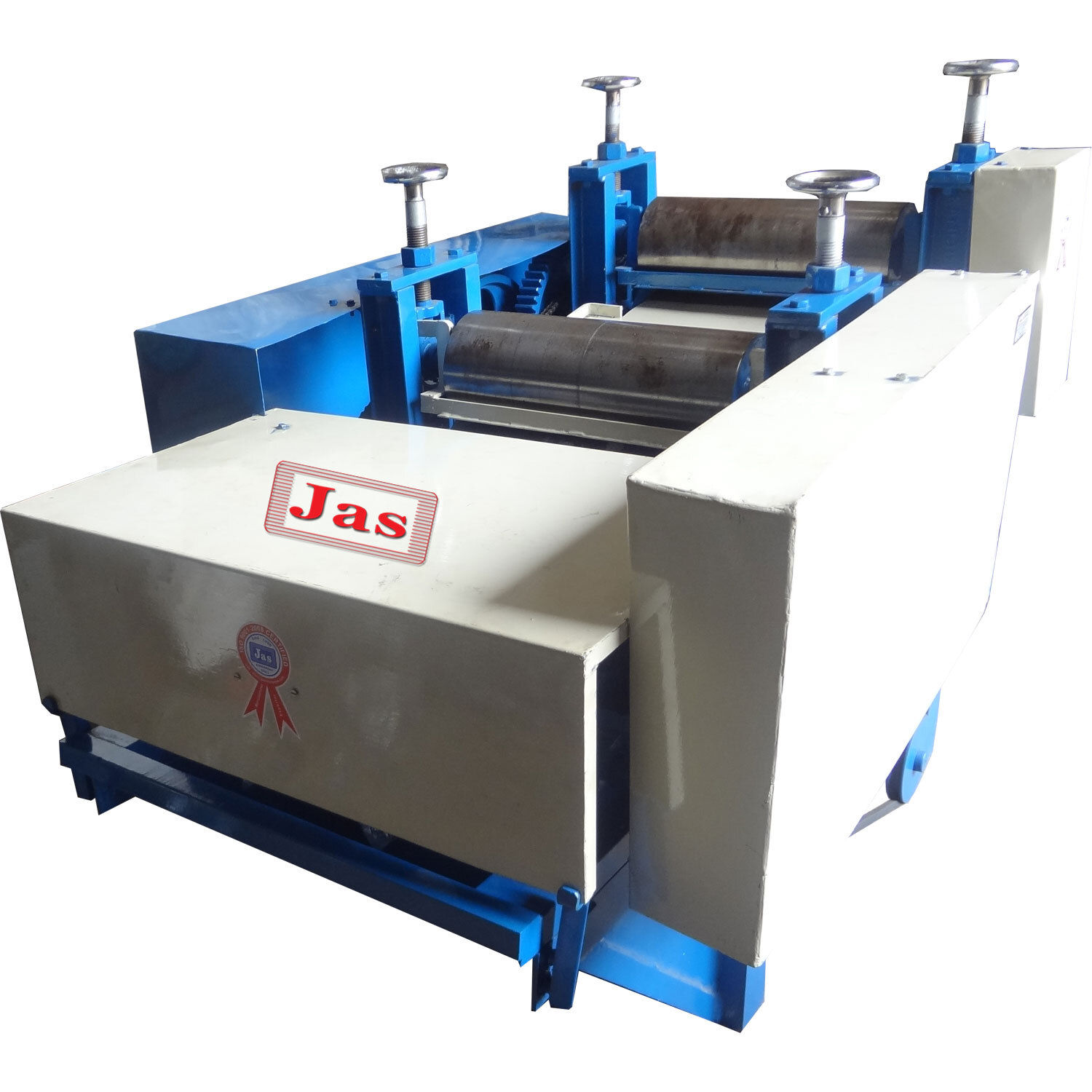

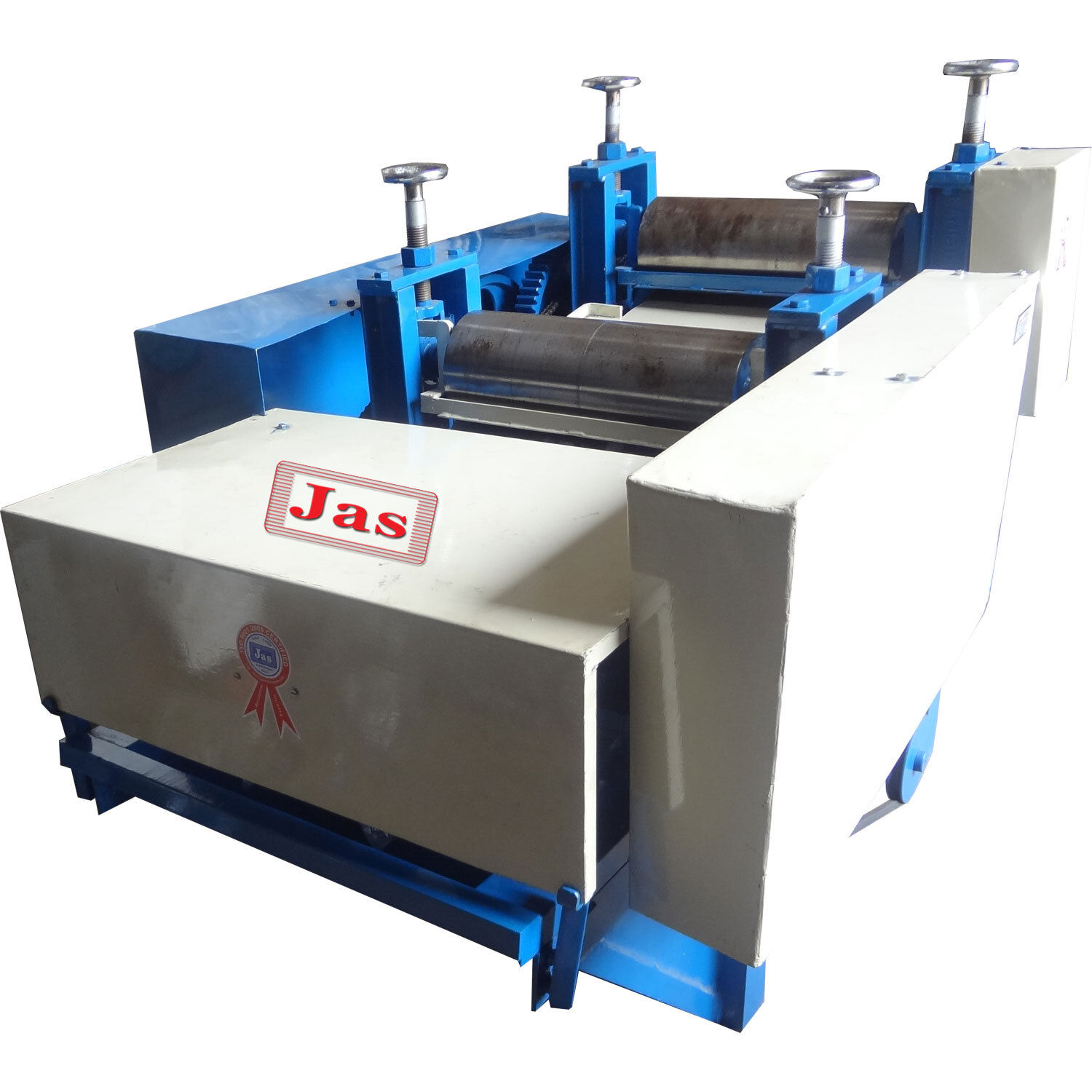

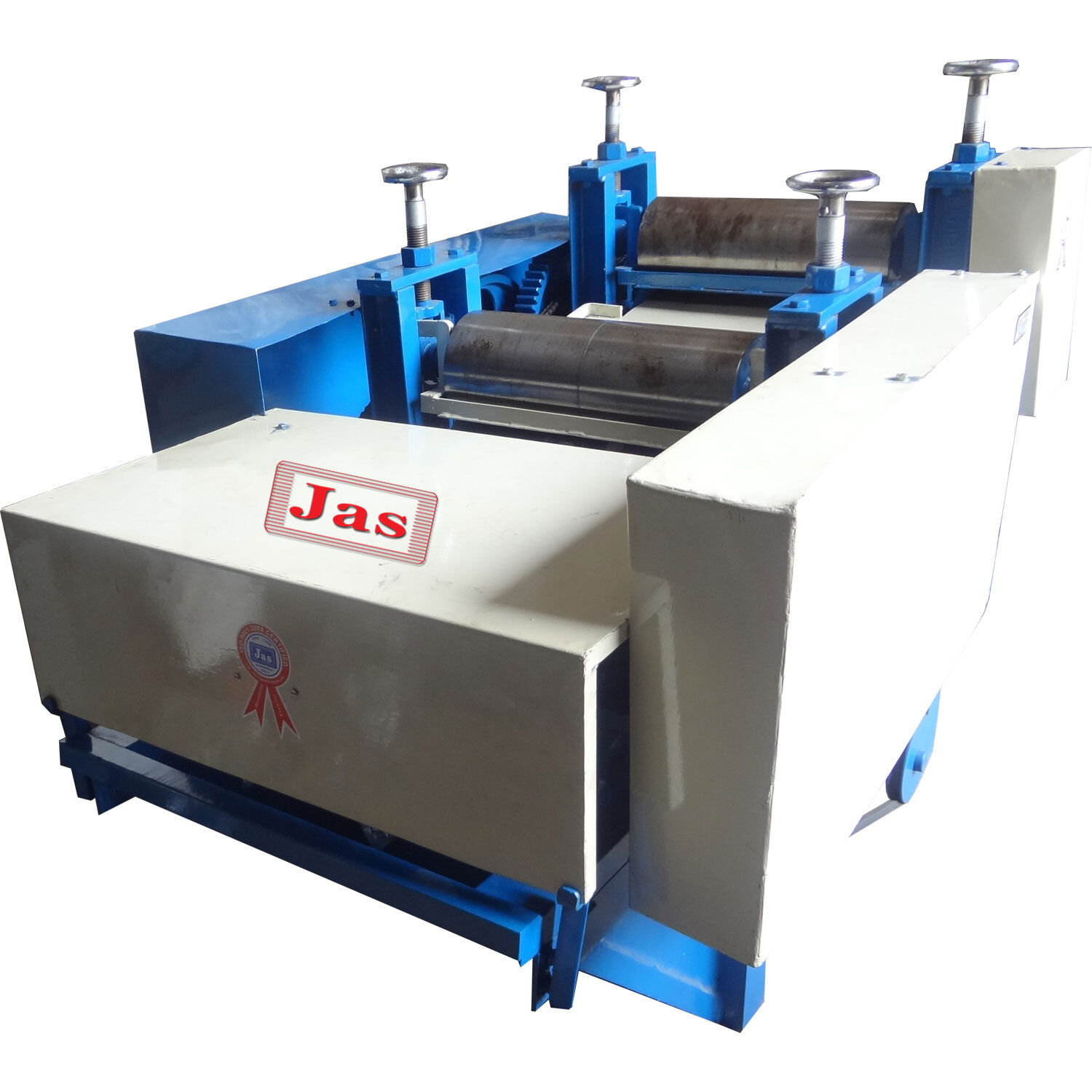

Nimki Making Machine

Nimki Making Machine Specification

- General Use

- for manufacturing NImki, khasta nimki, Ajwain and Kalonji Nimki, Namak para and many more Fried dough food

- Material

- Stainless Steel

- Product Shape

- Other

- Computerized

- No

- Automatic

- Yes

- Control System

- Manual

- Installation Type

- Free Stand

- Voltage

- 110-415 Volt (v)

- Power

- 2 - 15 Horsepower (HP)

- Raw Material

- Wheat

- Color

- Other

- Warranty

- 1 year against manufacturing defects at our site

Nimki Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- Assam, Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Nagaland, Uttarakhand, Daman and Diu, Lakshadweep, South India, North India, East India, Andaman and Nicobar Islands, Andhra Pradesh, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttar Pradesh, All India, Central India, West India, Chhattisgarh

- Certifications

- ISO 9001

About Nimki Making Machine

Nimki Making Machine

Jas enterprise have extensive knowledge of the namken, farsan and know how to design an effective process. We combine the latest technologies using computer simulation programs and build efficient and reliable process equipment. We take responsibility for design, manufacture and installation. We will commission the line and make sure that your staffs get professional training in maintenance and process control. Jas enterprise at present offers two kinds of namkeen, farsan processing line based on their production capacity and budgetary constraint. Products made by the namkeen extruder are: Gathiya or gathia bhavnagari gathiya, jamnagari gathiya, methi gathiya, makhaniya gathiya, Tum Tum and many more. Sev bhujia like aloo sev, garlic sev (lasun Sev), palak Sev (spinach sev), tomato sev, bikaneri bhujia, ratlami sev, nylon sev, and many more. Papadi or papdi This extruder can also be used for grating papaya and coconuts.

Efficient Production Process

This nimki making machine streamlines dough sheeting, slitting, and cutting, delivering consistently shaped fried snacks at a rapid pace. Its semi-automatic cutting function ensures precision, while electric drive enables smooth and reliable operation. Suitable for mass production, the machine maintains high output with minimal manual effort.

Durable Construction and Design

Crafted from high-grade steel and stainless steel, the machine promises longevity and resistance to wear. Its freestanding setup facilitates easy placement and relocation. Both the structural material and design ensure low maintenance and robust hygiene, crucial for food manufacturing environments.

User-Friendly Operation

Combining manual control with automatic operation, users can achieve desired results without requiring specialized skills. The control system is straightforward, allowing operators to adjust settings based on production needs, simplifying the process for manufacturers and suppliers alike.

FAQs of Nimki Making Machine:

Q: How does the Nimki Making Machine enhance the dough preparation process?

A: The machine automates dough sheeting, slitting, and cutting, enabling producers to achieve uniform thickness and perfectly shaped nimki and related snacks. This streamlining replaces multiple manual steps with a single, efficient process.Q: What is the primary usage of this machine in snack manufacturing?

A: It is principally used for manufacturing nimki varieties, khasta nimki, ajwain and kalonji nimki, namak para, and similar fried dough products, addressing the needs of commercial food producers and small businesses alike.Q: When is maintenance required for the Nimki Making Machine?

A: Routine cleaning after each production cycle is recommended to maintain hygiene. The machine is designed for minimal maintenance due to its sturdy steel and stainless steel construction. Should any manufacturing defect arise, it is covered under the one-year warranty.Q: Where can this machine be installed and operated most effectively?

A: Owing to its freestanding design, the machine can be installed in commercial kitchens, snack factories, and bakeries without the need for complex setup. Its electric drive system operates using 110415V, making it adaptable to various industrial environments.Q: What raw materials are compatible with this nimki making machine?

A: The machine is optimized for wheat-based dough but can also process other doughs suitable for making different types of fried snacks, provided they conform to standard recipes for these products.Q: How does manual control influence the operation despite its semi-automatic features?

A: Manual controls allow operators to make quick adjustments during processing, giving greater flexibility and control over the final product while still benefiting from the machines semi-automatic cutting efficiency.Q: What are the benefits of using this machine for large-scale food production?

A: Manufacturers enjoy increased productivityup to 200 kg per houralongside consistent snack quality, reduced labor costs, and simplicity in operation. The warranty and reliable construction further add to peace of mind for continuous operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Nimki Making Machine Category

Chilli Cutting Machine

Price Range 10000.00 - 20000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Automation Grade : Automatic

Voltage : 220240 V

Phase : Single Phase or Three Phase

Automatic : Yes

Vegetable Cutting Machine

Price Range 22000.00 - 100000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automation Grade : Automatic

Voltage : 220V

Phase : Single Phase

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS