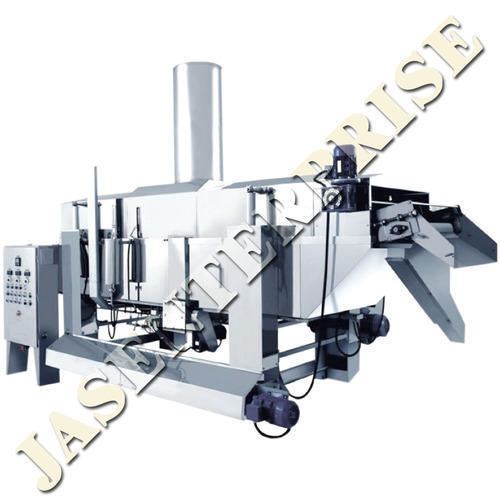

Potato Chip Line

Price 65000.00 INR/ Unit

Potato Chip Line Specification

- Material

- Stainless Steel

- Capacity

- 100 TO 500 Kg/hr

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Voltage

- 110-440 Volt (v)

- Power

- 10 TO 22 Horsepower (HP)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Warranty

- 1 Year Against Manufacturing Defect At Our Site

Potato Chip Line Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 1000 Units Per Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Manipur, Uttarakhand, Dadra and Nagar Haveli, Lakshadweep, , South India, North India, East India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Delhi, Daman and Diu, Gujarat, Goa, Haryana, Jammu and Kashmir, Karnataka, Kerala, Madhya Pradesh, Mizoram, Meghalaya, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Maharashtra, Uttar Pradesh, Bihar, Central India, Jharkhand, West India, Chhattisgarh, All India

- Certifications

- ISO 9001

About Potato Chip Line

Potato Chip Line

Semi automatic potato/banana chips line capacity: - 100 kg/hr products made by the line are

- Potato chips (plain , ruffles)

- Potato sticks (salli)

- Banana/plantain chips

Some of the main features of Semi automatic potato chips line are.

Food safety

- All contact materials and components are food grade to ensure food safety.

- Oil filtration system prolongs cooking oil life time which promotes better product shelf life.

- Oil enters the fryer kettle through strategically places inlets to ensure even temperature across the fryer.

- Fryer is automatically control to stabilize cooking oil temperature.

- Cooking time is adjusted by controlling fryers conveyor speed.

Engineering excellence

- Jas semi automatic potato chips line are made of high quality components and material to ensure endurance and high performance.

- Semi automatic potato chips line are designed to work around the clock with minimum downtime.

- Semi automatic potato chips line are comes in various sizes and configurations to meet different product and capacity requirements.

- Potato peeler

- Potato chips slicer

- Hydro Extractor

- Hopper with Metered Feeder

- Shaker

- Frying System Heat Exchanger

- Oil Tank

- Control Panel

Fuel : Diesel, LPG, Natural Gas

Material of Construction : AISS-304 Grade Stainless Steel

Advanced Automation and Control

Equipped with computerized PLC control, this potato chip line offers streamlined operations and precise quality management. The automatic system minimizes manual intervention, reducing human error and ensuring consistent results batch after batch.

Eco-Friendly and Energy Efficient

The machine is designed with environmental sustainability in mind. It operates quietly with lower energy consumption, requiring only 1022 horsepower, which helps businesses reduce operational expenses and carbon footprint, while maintaining high production efficiency.

Flexible Capacity and Compact Build

Featuring a compact structure, the line fits efficiently into various production spaces and can handle payloads from 100 up to 500 kg per hour. Stainless steel construction ensures product hygiene and long-term durability, tailored for the needs of commercial kitchens and factories.

FAQs of Potato Chip Line:

Q: How does the potato chip line contribute to environmental sustainability?

A: The potato chip line is designed with eco-friendly features such as lower energy consumption and a quiet operation, significantly reducing both power usage and noise pollution in food processing environments.Q: What control system does the potato chip line utilize for operation?

A: The system uses a PLC (Programmable Logic Controller) for computerized control, enabling precise management of the production process and facilitating ease of operation and monitoring.Q: Where can I purchase or find support for this potato chip line in India?

A: You can acquire the potato chip line or receive support through a wide network of distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers located throughout India.Q: What is the warranty policy for the potato chip line?

A: The product includes a 1-year warranty against manufacturing defects, with service provided at your site for prompt and convenient support.Q: What process does the chip line use to guarantee high efficiency and output?

A: Featuring a fully automatic, computerized workflow with a capacity of 100 to 500 kg/hr, the line ensures high efficiency by optimizing each stage, from slicing to frying and packaging, with minimal manual intervention.Q: What types of material are used in the construction of the potato chip line?

A: The machine is made from stainless steel, ensuring hygiene, durability, and resistance to corrosion, all of which contribute to superior product quality and reduced maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Potato Chips Making Machines Category

Chips Making Machine

Price 30000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 12 Horsepower (HP)

Feature : Other, Low Maintenance, Energy Efficient, High Performance

Material : Stainless Steel

Potato Peeler Machine

Price Range 25000.00 - 75000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 750 Watt (w)

Feature : Low Noice, Lower Energy Consumption, ECO Friendly, High Efficiency, Compact Structure

Material : Stainless Steel

Potato Chips Making Machines

Price 23000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 7501500 Watt (w)

Feature : High Efficiency, ECO Friendly, Low Noice

Material : Stainless Steel

Potato Peelers

Price Range 15000.00 - 90000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 0.5 to 3 Horsepower (HP)

Feature : ECO Friendly, Lower Energy Consumption, High Efficiency, Low Noice, Compact Structure

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS