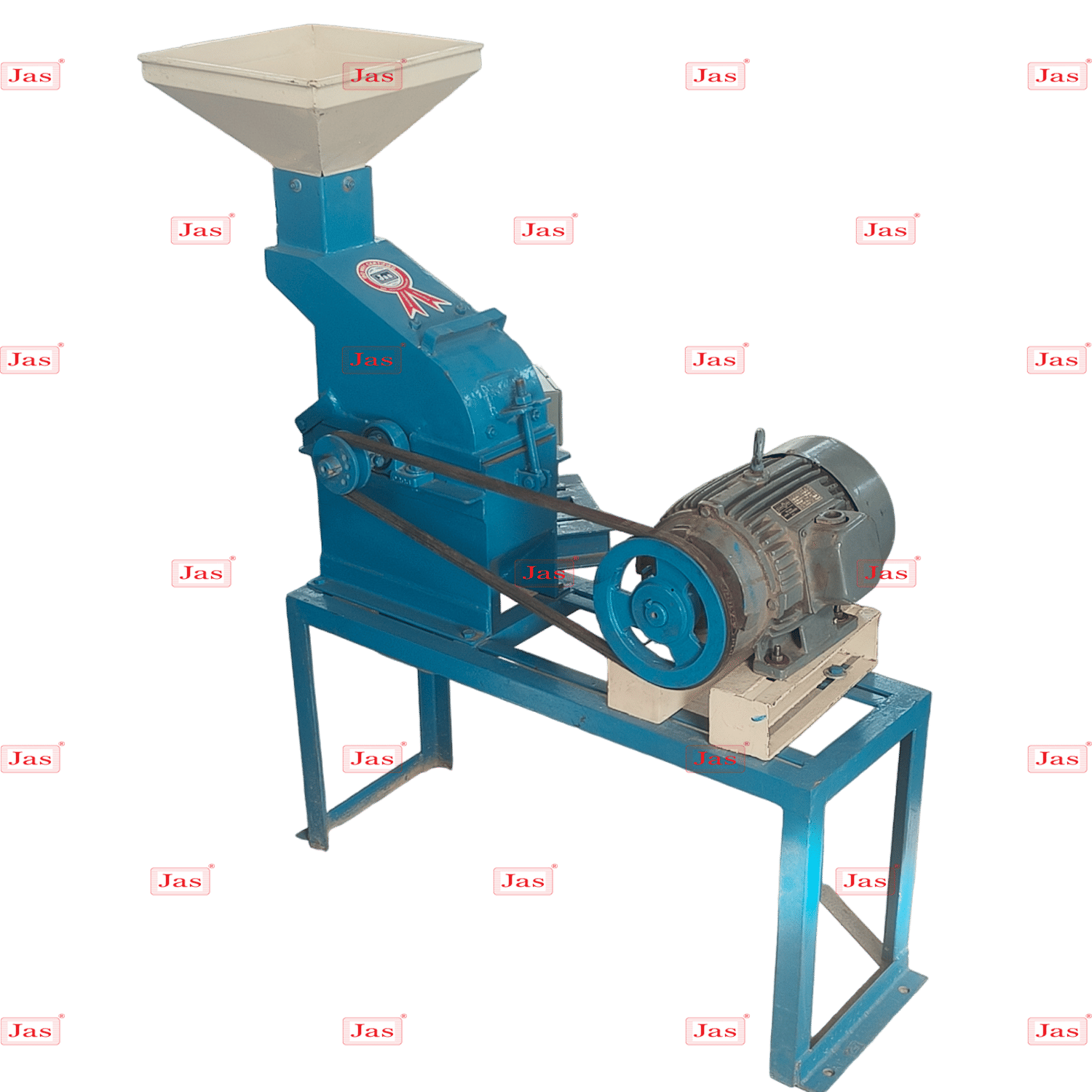

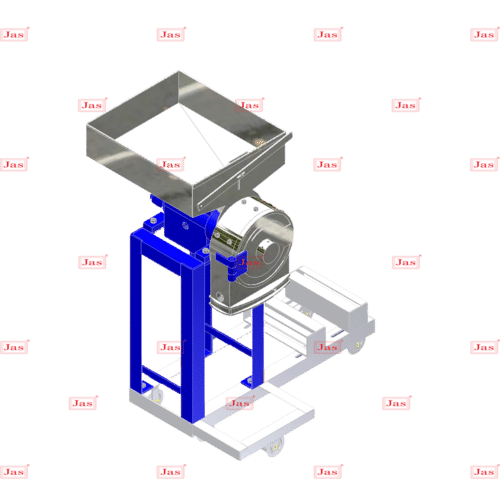

Pulverizing Machine

Price 18000 INR/ Unit

Pulverizing Machine Specification

- Material

- Stainless Steel

- Capacity

- 20-2200 Kg/hr

- Automatic

- Yes

- Control System

- Manual

- Voltage

- 230/440 Volt (v)

- Feature

- High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

- Color

- Blue

- Warranty

- 1 Year

Pulverizing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, Australia

- Main Domestic Market

- Manipur, Andhra Pradesh, Bihar, Chandigarh, All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Pulverizing Machine

-

Hammer Mills: These use rotating hammers to crush and grind materials. Theyre often used for grinding grain, wood chips, and other bulk materials.

-

Ball Mills: These consist of a rotating drum filled with balls (usually made of steel or ceramic). As the drum rotates, the balls grind the material into a fine powder. Theyre commonly used in mining and manufacturing.

-

Raymond Mills: These are used to pulverize materials into a fine powder for use in various industries, including mining, metallurgy, and construction. They use a combination of grinding rolls and a rotating classifier.

-

Jet Mills: These use high-velocity air streams to pulverize materials. Theyre often used for materials that need to be ground very finely, such as in the pharmaceutical or chemical industries.

-

Roller Mills: These use two or more cylindrical rollers to crush and grind materials. Theyre frequently used in the production of flour and feed.

-

Disc Mills: These use rotating discs to grind and crush materials. Theyre used for processing grains and other materials that require a finer texture.

Eco-Friendly and Efficient Operations

Enjoy environmentally conscious pulverization with reduced noise and minimal energy consumption. This machine is engineered to prioritize high performance while maintaining eco-friendly standards, making it an excellent choice for sustainable industrial practices. Its innovative design helps you lower operational costs and improve productivity.

Wide Range of Capacities and Applications

With a broad capacity range from 20 to 2200 kg/hr, this pulverizing machine handles diverse processing volumes. It is perfect for businesses of all sizes in food, chemical, or pharmaceutical sectors, catering to small batches or large industrial requirements without compromising output quality.

User-Friendly Manual Control

While the pulverizing process is automatic, the machine is equipped with a manual control system for straightforward operation and fine-tuned adjustments. This ensures operators can easily manage and monitor the process, enhancing safety and output consistency with minimal training.

FAQs of Pulverizing Machine:

Q: How does the pulverizing machine ensure high performance and efficiency?

A: The machine is engineered with high-quality stainless steel components and advanced mechanisms designed for efficient material breakdown. Its automatic operation and high throughput range from 20 to 2200 kg/hr guarantee consistent, energy-saving performance while minimizing noise.Q: What types of materials can be processed with this pulverizing machine?

A: This pulverizer is suitable for a wide range of materials including grains, spices, herbs, minerals, and certain industrial chemicals. Its robust build and capacity allow it to handle various textures and sizes with reliable output quality.Q: When is this pulverizing machine most beneficial for industrial use?

A: The machine is ideal for continuous processing in environments where high efficiency, low energy consumption, and noise reduction are essential. It proves especially beneficial during long production runs or when transitioning between different material types due to its flexible capacity and adjustability.Q: Where can I purchase this pulverizing machine in India?

A: The machine is widely available throughout India via distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers. Buyers can conveniently access it from major industrial equipment providers across the country.Q: What is the process for operating the pulverizing machine?

A: Using the machine involves loading the raw material into the feeding hopper, adjusting the manual control settings as needed, and activating the system. The automatic mechanism pulverizes the material efficiently, with operators able to monitor and make necessary adjustments via the control interface.Q: How does the eco-friendly feature benefit my operations?

A: Its eco-friendly design not only reduces environmental impact through lower energy use and quieter operation, but also helps decrease utility costs and promotes a safer, more pleasant workplace for operators.Q: What warranty and support options are available for this machine?

A: The pulverizing machine comes with a 1-year warranty covering major components and manufacturing defects. Comprehensive support is available through the supplier network in India, ensuring quick response times for servicing or spare parts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding, crushing and Pulverizing Machine Category

Mill Masala Mill

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 440 Volt (v)

Capacity : 30 to 160 Kg/hr

Material : Stainless Steel

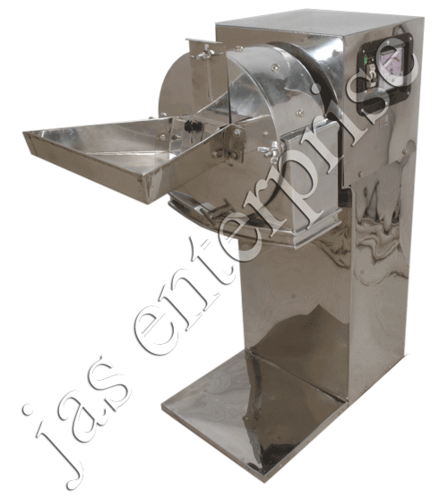

Semi Automatic Micro Pulverizer

Price 11500 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : No

Voltage : 230/440 Volt (v)

Material : Stainless Steel

Coriander Grinder Machine

Price 56000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : No

Voltage : 220/440 Volt (v)

Capacity : 30160 Kg/hr

Maize Grinding Hammer Mill

Price 15000.00-650000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 20 to 2200 Kg/hr

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS