Red Chilli PoundingExporters

Price 41000 INR/ Unit

Red Chilli PoundingExporters Specification

- Capacity

- 8-20 Kg/hr

- Automatic

- Yes

- Power

- 1/2 Horsepower (HP)

- Voltage

- 230/440 Volt (v)

- Feature

- High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Red Chilli PoundingExporters Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Red Chilli PoundingExporters

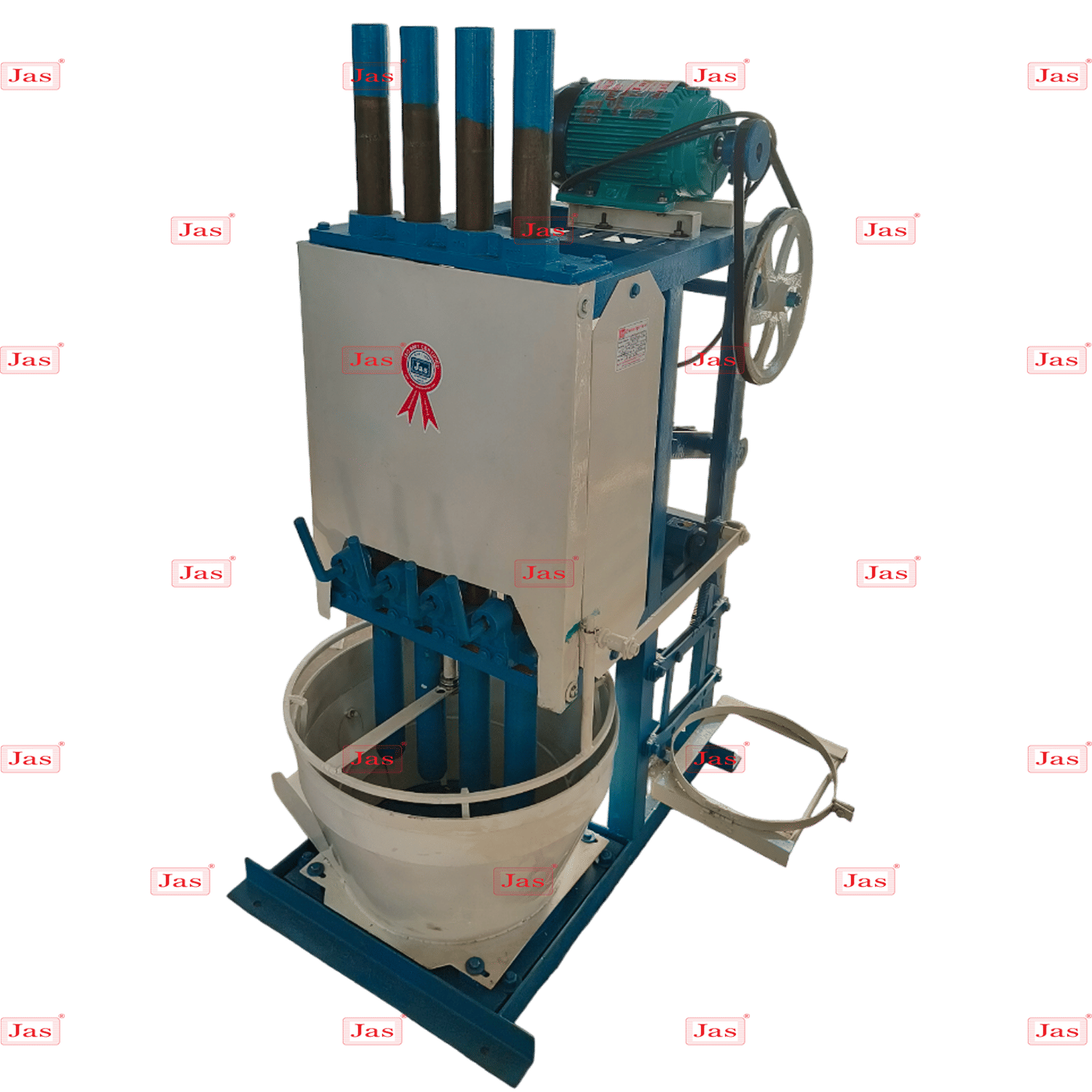

The machine typically consists of a hopper where the dried chilies are fed into, a grinding mechanism that pulverizes the chilies into the desired consistency (chunks or powder), and a collection container where the processed chilies are gathered.

Key features of a chili pounding machine may include:

-

Grinding Mechanism: This could be in the form of blades, burrs, or a hammer mill, depending on the machines design and intended use.

-

Adjustable Settings: Some machines allow for adjustments in the fineness of the grind, catering to different culinary or industrial requirements.

-

Material Construction: Stainless steel is often used for parts that come into contact with food to ensure hygiene and durability.

-

Capacity: Machines can vary greatly in terms of the amount of chilies they can process per hour, from small-scale machines for home use to industrial-sized units for large-scale production.

-

Power Source: Depending on the size and design, these machines can be powered by electricity, diesel engines, or even manually operated.

Advanced Pounding Technology

Our Red Chilli Pounding machines leverage automatic technology to deliver consistent and precise grinding, maximizing output while minimizing manual intervention. These machines are engineered for reliability and efficiency, making them ideal for commercial spice production.

Eco-Friendly and Quiet Operation

These machines incorporate energy-saving mechanisms and low-noise design, reducing environmental impact and creating a comfortable workspace. Their advanced engineering results in lower power consumption without sacrificing performance, aligning with modern sustainability practices.

FAQs of Red Chilli PoundingExporters:

Q: How does the automatic Red Chilli Pounding machine improve productivity?

A: The automatic feature significantly reduces manual labor and speeds up the grinding process, enabling users to process 820 kg of red chillies per hour with consistent quality and minimal supervision.Q: What steps are involved in the red chilli pounding process with this machine?

A: Users load cleaned and dried red chillies into the hopper, adjust the settings, and switch on the machine. The pounding mechanism then crushes and grinds the chillies efficiently while maintaining product quality and uniformity.Q: When is the best time to use this machine for commercial purposes?

A: The machine is ideal for continuous batch processing during working hours. Its high efficiency and low noise level make it suitable for use throughout the day in spice production factories, stores, or distribution centers.Q: Where can distributors and exporters source these Red Chilli Pounding machines in India?

A: Distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers can obtain these machines from trusted industrial equipment suppliers located across India, specializing in high-performance food processing machinery.Q: What are the main benefits of using this machine for red chilli processing?

A: The key benefits include high output, reduced energy consumption, minimal noise, eco-friendly operation, exceptional grinding consistency, and significant savings in labor and operational costs.Q: How energy-efficient is the Red Chilli Pounding machine?

A: Operating on 1/2 HP and 230/440 Volt power, the machine is designed for lower energy consumption. This not only cuts electricity expenses but also contributes to sustainable manufacturing practices.Q: What measures ensure the machines high performance and safety during use?

A: The machines robust construction, automatic controls, and thermal protection system guarantee safe operation and consistent high efficiency while mitigating common hazards related to overheating and overloading.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding, crushing and Pulverizing Machine Category

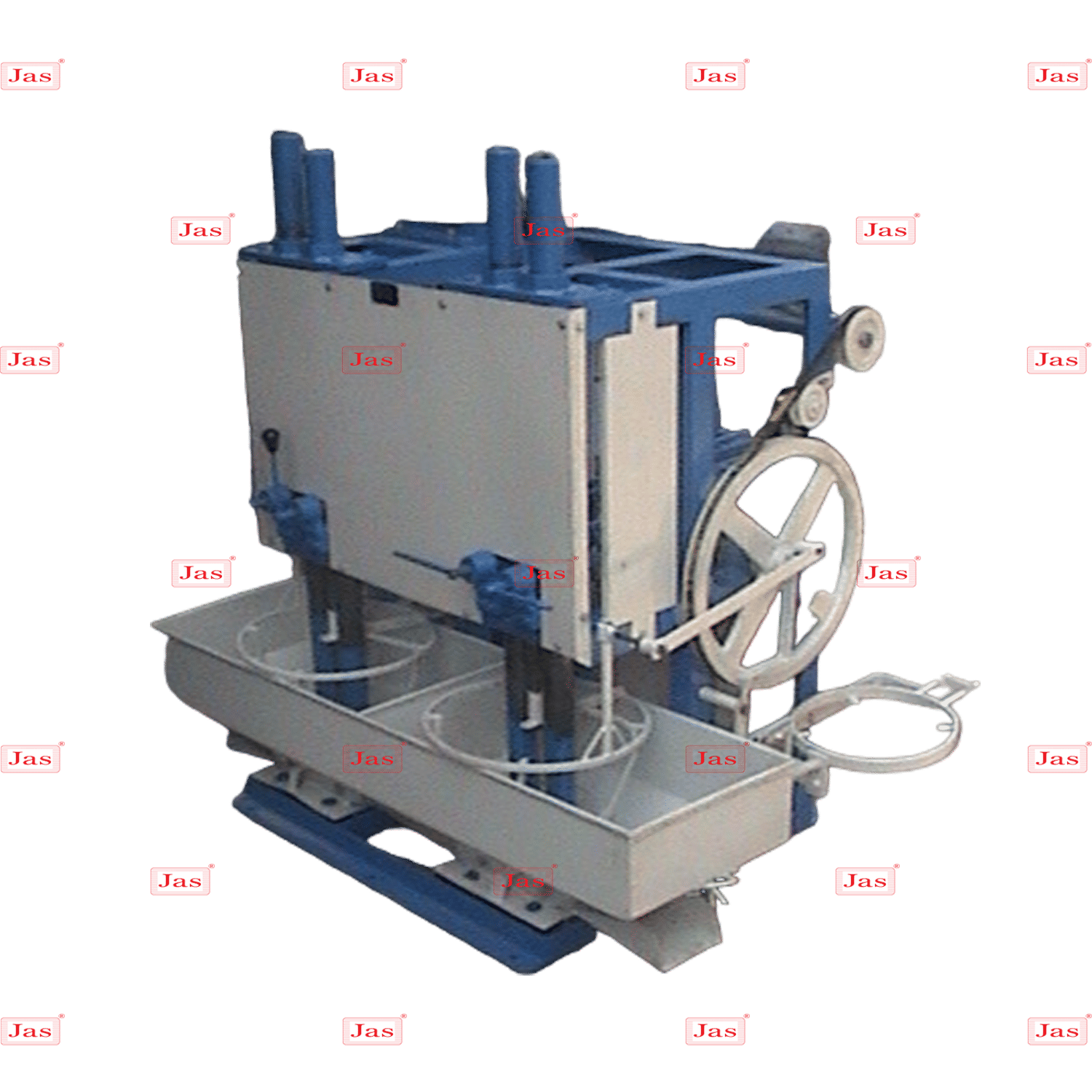

Red Chilli Pounding

Price 41000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Voltage : 230/440 Volt (v)

Automatic : Yes

Capacity : 820 Kg/hr

Herb Grinder

Price 56000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Voltage : 230/440 Volt (v)

Automatic : Yes

Capacity : 30160 Kg/hr

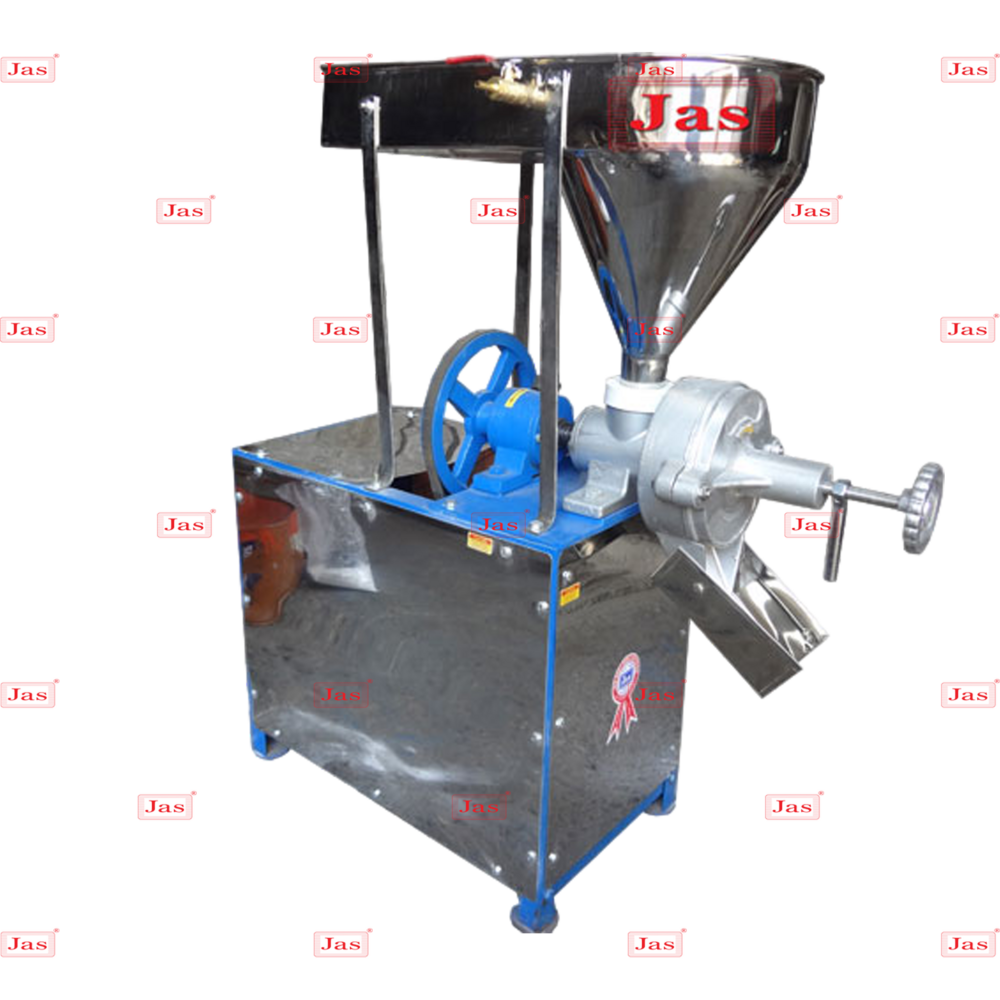

Small Millet Processing Machine

Price 30000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Voltage : 230/440 Volt (v)

Automatic : No

Capacity : 8200 Kg/hr

Rice Powder Grinding Machine

Price 24000 INR / Piece

Minimum Order Quantity : 1 Unit

Feature : High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Voltage : 230/440 Volt (v)

Capacity : 30100 Kg/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free