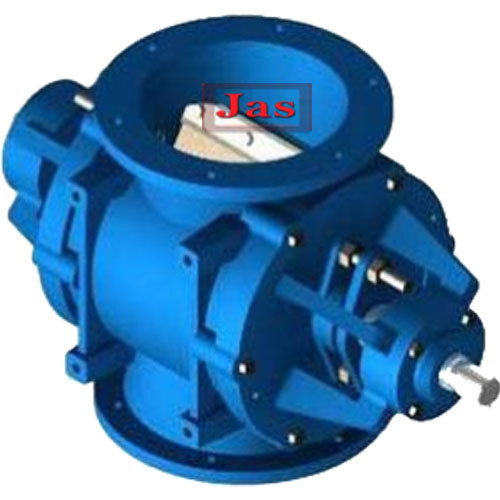

Rotary Airlock Feeder And Valve

Price 10000 INR/ Unit

MOQ : 1 Unit

Rotary Airlock Feeder And Valve Specification

- Computerized

- No

- Automatic

- Yes

- Installation Type

- Free Stand

- Voltage

- 110 to 440 Volt (v)

- Power

- 3 HP Horsepower (HP)

- Feature

- High Efficiency, Lower Energy Consumption, ECO Friendly, Low Noice, Compact Structure

- Warranty

- One year against manufacturing defects at our site

Rotary Airlock Feeder And Valve Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahemadabad

- Supply Ability

- 10000 Units Per Month

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Sikkim, Pondicherry, Daman and Diu, , South India, North India, East India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Lakshadweep, Nagaland, Odisha, Punjab, Rajasthan, Tamil Nadu, Telangana, Tripura, Uttarakhand, West Bengal, Uttar Pradesh, Haryana, Kerala, Central India, West India, Chhattisgarh, All India

- Certifications

- ISO 9001

About Rotary Airlock Feeder And Valve

We, at Jas Enterprise design and manufacture one of the most vital products in industrial powder handling process. This are called Rotary Air Lock Feeder/valve. Handling powder material is a very complicated process and unless we discuss and understand our buyers exact requirement, then only we go into the further process. This is our fundamental policy since 1990, when we put our foot into the Rotary Air Lock Valves manufacturing activities.Our clients are our friends and we ask them to give us full feedback of their requirement and then it becomes our responsibility to ensure that they get most efficient Rotary Air Lock Valve from us and that they will not face any problem or worries. we can supply different type of valves like Couple Drive Rotary Air Lock Valve, Rotary Valve with Direct Mount Geared Motor, Rotary Valve with Sight Glass, V belt Drive Rotary Air lock Valve, Rotary Air lock Valve with vfd for different speed.

Applications

Rotary airlock feeders/valves have wide application in industry wherever dry free-flowing powders, granules, crystals, or pellets are used. Typical materials include

- Cement

- Ore

- Sugar

- Minerals

- Grains

- PVC Chips

- Dust

- Fly ash

- Starch

- Guar gum Powder

- Flour

- Gypsum

- Lime

- Coffee

- Cereals

- Pharmaceuticals

Rotary feeders are ideal for pollution control applications in wood, grain, food, textile, paper, tobacco, rubber, and paint industries. The Standard Series works beneath dust collectors and cyclone separators even with high temperatures and different pressure differentials.

Our valves are available in size 150 mm to 400 mm on regular basis with material of construction like Cast Iron, Cast Steel, Cast SS 304, 316, 316L etc.

Superior Efficiency and ECO-Friendly Operation

This rotary airlock feeder incorporates advanced features like low energy consumption and reduced noise levels, making it ideal for modern industrial setups. Its compact design allows seamless integration into existing processes, contributing to a cleaner workspace and improved operational efficiency.

Reliable and Easy Installation

Designed for automatic operation, the free-standing installation type simplifies setup, minimizing downtime so your facility can quickly benefit from its robust performance. The units durability is backed by a one-year warranty against manufacturing defects at the installation site.

FAQs of Rotary Airlock Feeder And Valve:

Q: How is the Rotary Airlock Feeder And Valve installed in an industrial setting?

A: This feeder is designed for free-standing installation, which enables a straightforward, hassle-free setup without the need for intricate mounting hardware, making it suitable for varying industrial environments.Q: What processes benefit most from using this rotary airlock feeder?

A: The rotary airlock feeder is highly effective for material handling applications that require precise feeding and airlock functionality, such as pneumatic conveying systems, bulk solids handling, and dust collection operations.Q: When does this feeder require maintenance or service?

A: Routine maintenance is minimal due to its compact and robust structure. However, periodic inspection is advised to ensure optimal performance, with the added reassurance of a one-year manufacturers warranty against defects.Q: Where is this product distributed and available for installation?

A: The Rotary Airlock Feeder and Valve is available through distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers across India, ensuring widespread accessibility for industrial clients.Q: What are the main benefits of using this high efficiency rotary airlock feeder?

A: Users will experience lower operational costs due to its lower energy consumption, less ambient noise, environmentally considerate design, automatic operation, and overall improved reliability in handling materials.Q: Is the valve compatible with varying voltage and power needs?

A: Yes, the feeder operates across a broad voltage range from 110 to 440 volts and utilizes a 3 HP motor, making it suitable for diverse electrical setups typically encountered in industrial operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Food Processing Machinery Category

Idli Steamer Gas

Price 15000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 440 Volt (v)

Computerized : No

Feature : Other, Rust Proof, Durable Construction, Energy Efficient

Khichu Making Machine

Price 25000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110440 Volt (v)

Computerized : No

Pasta Extruder Machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 440 Volt (v)

Computerized : No

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Juice Press

Price 6800 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 440 Volt (v)

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free