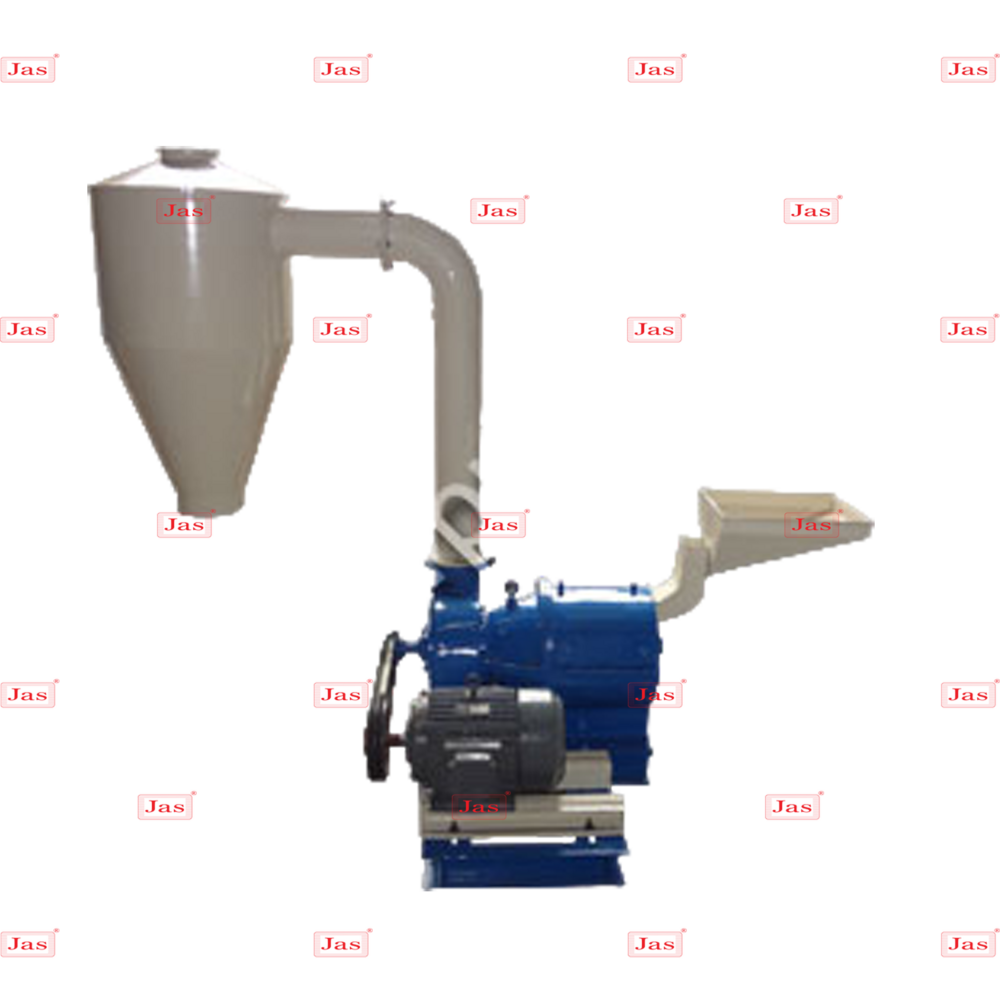

Sattu Plant

Price 190000 INR/ Unit

Sattu Plant Specification

- Phase

- Single Phase / Three Phase

- Frequency

- 50-60 Hertz (HZ)

- General Use

- Industrial

- Material

- Stainless Steel

- Capacity

- 30-2000 Kg/hr

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Voltage

- 230/440 Volt (v)

- Power

- 2-200 Horsepower (HP)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Warranty

- One year against manufacturing defect at our side

Sattu Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Delivery Time

- 5-10 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Sattu Plant

A Sattu Plant is a specialized agro-processing facility designed to produce sattu, a traditional Indian flour made primarily from roasted Bengal gram (chana), though other grains like barley or maize can also be used. Sattu is widely valued for its high nutritional content, being rich in protein, fiber, iron, and essential nutrients, and is a key ingredient in many traditional Indian foods and health drinks.

The process of manufacturing sattu involves several stages, each requiring specific machinery and technical precision to maintain the nutritional value and taste of the final product.

Efficient and Flexible Sattu Production

Our Sattu Plant supports capacities from 30 to 2000 kg per hour, making it suitable for both emerging enterprises and established manufacturers. Built with stainless steel, it ensures food safety and durability for long-term industrial use. The system's manual controls and voltage flexibility allow seamless integration into existing setups, offering high efficiency with eco-friendly performance.

Practical Eco-Friendly Design

This Sattu Plant stands out for its eco-conscious design, quiet operation, and compact structure that fits a variety of industrial spaces. Its low energy requirements help reduce operational costs while maintaining high output quality. Users benefit from easy maintenance and the assurance of a one-year warranty against manufacturing defects, ensuring reliable performance.

FAQ's of Sattu Plant:

Q: How does the Sattu Plant operate in an industrial setting?

A: The Sattu Plant functions using a manual control system, allowing operators to manage the production process efficiently. Connected to a single-phase or three-phase power supply, it processes raw ingredients into Sattu flour at capacities tailored to your requirements.Q: What materials are used in the construction of the Sattu Plant?

A: The plant is constructed entirely from high-grade stainless steel, ensuring enhanced durability, corrosion resistance, and compliance with food safety standards, making it ideal for industrial Sattu production.Q: When is maintenance typically required for this machine?

A: Basic maintenance, including cleaning and inspection, should be performed after each production cycle. Regular preventive checks can help ensure optimal performance and are covered under the one-year warranty for manufacturing defects.Q: Where can the Sattu Plant be installed and used?

A: It is ideal for industrial environments such as food processing factories, large-scale kitchens, and production facilities throughout India. Its compact design allows for flexible installation in varying industrial spaces.Q: What is the process involved in producing Sattu using this machine?

A: The process includes feeding the required grains or pulses into the stainless steel unit, where they are roasted, ground, and sieved according to your preset manual controls, resulting in high-quality Sattu powder.Q: How does the Sattu Plant benefit my business operations?

A: With its high processing efficiency, low energy consumption, and eco-friendly operation, the Sattu Plant reduces production costs, increases output, and ensures a reliable supply of quality Sattu, boosting business profitability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Grains Processing Machines Category

Mini Dal Mill Machine

Price 170000 INR / Unit

Minimum Order Quantity : 01 Unit

Feature : ECO Friendly, Compact Structure, Lower Energy Consumption, High Efficiency

Automatic : Yes

Warranty : 6 months against any manufacturing defects.

Besan Sattu Making Machine

Price 30000 INR / Piece

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Warranty : One year against manufacturing defect at our side

Pulse Lentils Polishers

Price Range 50000.00 - 95000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Lower Energy Consumption, ECO Friendly, High Efficiency, Low Noice, Compact Structure

Automatic : Yes

Warranty : One year against manufacturing defects at our site, except all wear and tear parts.

Peanut Frying Machine

Price 10500 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly

Warranty : 1 Year

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS