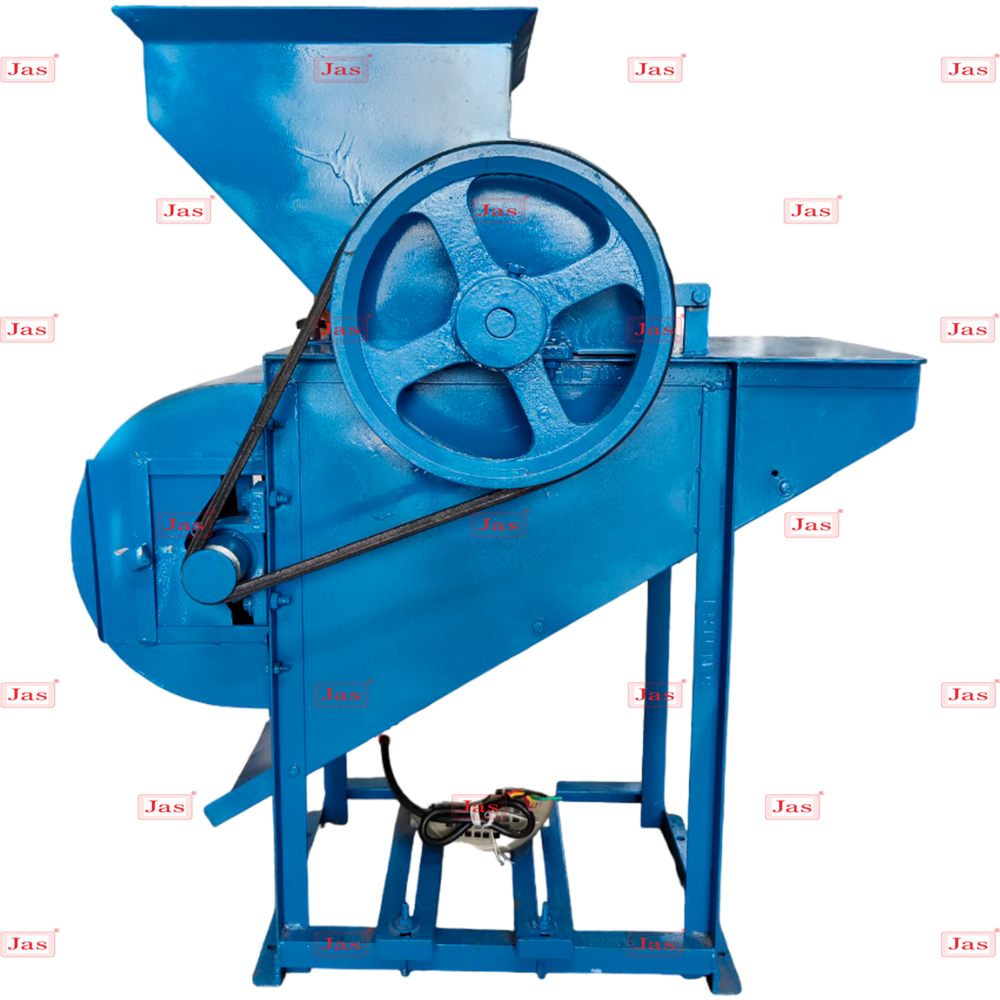

Sawdust Dryer Machine

Price 390000 INR/ Unit

Sawdust Dryer Machine Specification

- Capacity

- 30-2500 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Sawdust Dryer Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Sawdust Dryer Machine

Types of Sawdust Dryers:

-

Rotary Drum Dryer:

- How It Works: A rotating drum tumbles the sawdust while hot air is blown through it. This method is efficient for large quantities and is suitable for continuous operation.

- Pros: High capacity, efficient drying, and can handle varying sizes of sawdust.

- Cons: Requires significant space and energy.

-

Airflow Dryer:

- How It Works: Hot air is passed through a stream of sawdust. This type is often used for smaller quantities and can be more compact.

- Pros: Compact size and lower energy consumption.

- Cons: Less efficient for large volumes and may require more frequent maintenance.

-

Flash Dryer:

- How It Works: Sawdust is suspended in a hot air stream and dried rapidly. This is ideal for fine sawdust and smaller volumes.

- Pros: Fast drying time and compact design.

- Cons: Can be more complex and expensive.

-

Belt Dryer:

- How It Works: Sawdust moves along a conveyor belt while hot air is circulated around it. This method is suited for continuous drying and is often used for larger volumes.

- Pros: Continuous operation and efficient for large quantities.

- Cons: Higher initial cost and requires more space.

Key Features to Consider:

- Capacity: Choose a machine based on the volume of sawdust you need to dry.

- Energy Efficiency: Look for machines that use energy efficiently to reduce operating costs.

- Temperature Control: Precise temperature control helps prevent overheating and preserves the quality of the sawdust.

- Maintenance: Consider the ease of maintenance and availability of replacement parts.

Robust and Reliable Drying Technology

The Sawdust Dryer Machine employs advanced automation to deliver consistent and uniform drying. Its compact and eco-friendly design minimizes space requirements while keeping energy usage low. The machines high efficiency means faster drying cycles, making it a dependable solution for industries focused on bioenergy and wood processing.

Versatile Applications for Every Sector

Ideal for use by distributors, exporters, manufacturers, retailers, and traders across India, the machine is tailored for both large-scale industries and smaller enterprises. Its broad capacity range accommodates different production needs, ensuring flexible and scalable operations for various sawdust processing requirements.

FAQs of Sawdust Dryer Machine:

Q: How does the Sawdust Dryer Machine operate automatically?

A: The Sawdust Dryer Machine utilizes an automated control system that manages temperature, airflow, and drying cycles. This ensures consistent moisture reduction in sawdust, freeing operators from manual supervision and increasing productivity overall.Q: What are the main benefits of using this sawdust dryer?

A: The machine offers eco-friendly operation, lower energy consumption, low noise output, and high efficiency. Its compact structure also allows it to fit into limited spaces, making it suitable for a wide range of commercial and industrial settings.Q: When should you use a sawdust dryer machine?

A: A sawdust dryer machine is recommended whenever raw sawdust has high moisture content and needs to be processed for biofuel, pellets, or other wood products. It is especially useful in wood processing plants, biomass fuel plants, and carpentry workshops.Q: Where can I purchase or source the Sawdust Dryer Machine in India?

A: The machine is available across India through a network of distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers. This wide availability ensures accessibility for different business sizes and needs.Q: What is involved in the sawdust drying process?

A: The drying process involves feeding wet sawdust into the machine, where hot air or heat circulates to reduce moisture content. The automated system efficiently controls drying parameters to produce evenly dried sawdust.Q: How energy efficient is the Sawdust Dryer Machine?

A: This sawdust dryer is built with energy-saving components and optimized heat systems, resulting in lower electricity consumption while maintaining high drying performance. It operates on 230 or 440 volts, making it adaptable to various industrial power supplies.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Industrial Flavoring Drum

Price 45000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Lower Energy Consumption, High Efficiency

Capacity : 12580 Kg/hr

Voltage : 230/440 Volt (v)

Automatic : Yes

Corn Grinder

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, High Efficiency, Compact Structure

Capacity : 10 to 100 Kg/hr

Voltage : 110440 Volt (v)

Automatic : Yes

Fruits And Vegetables Dryer

Price 390000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Capacity : 302500 kg/batch Kg

Voltage : 400 Volt (v)

Peanut Processing Plant

Price 345000 INR / Piece

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Capacity : 501000 Kg/hr

Voltage : 230/440 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS