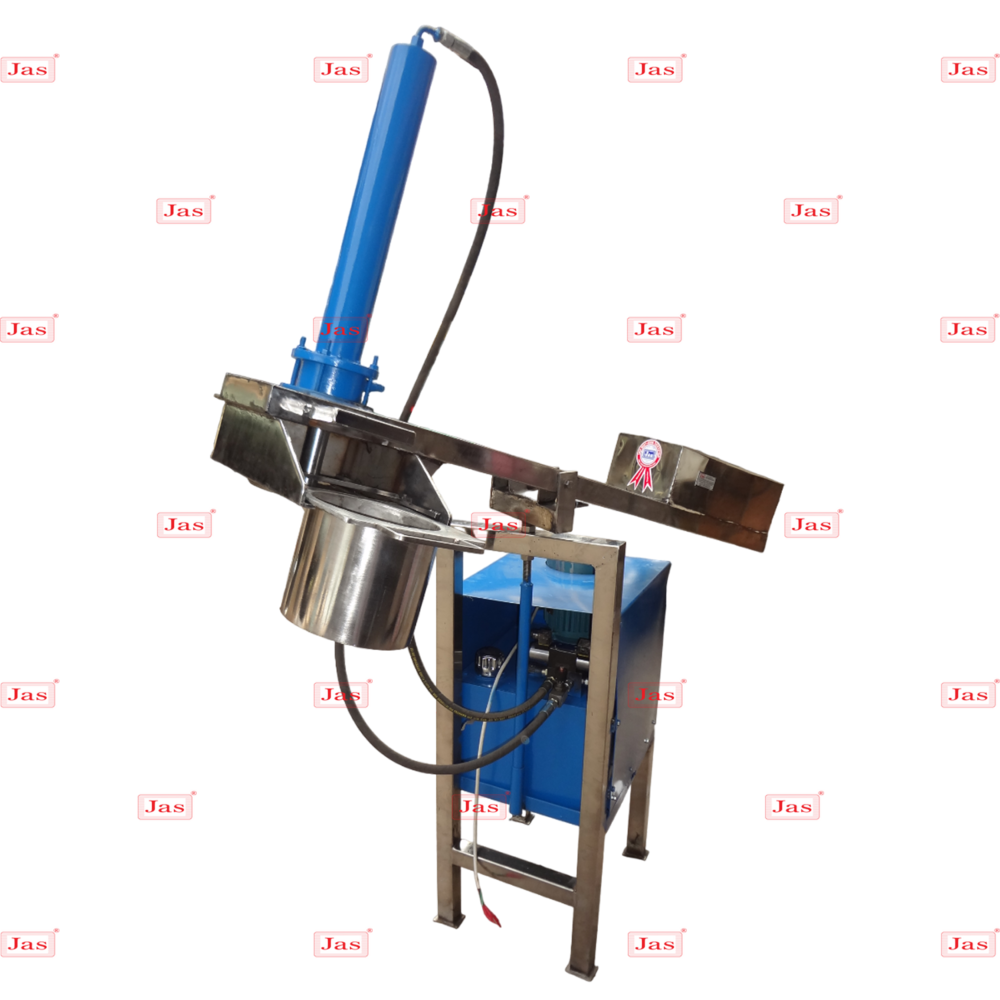

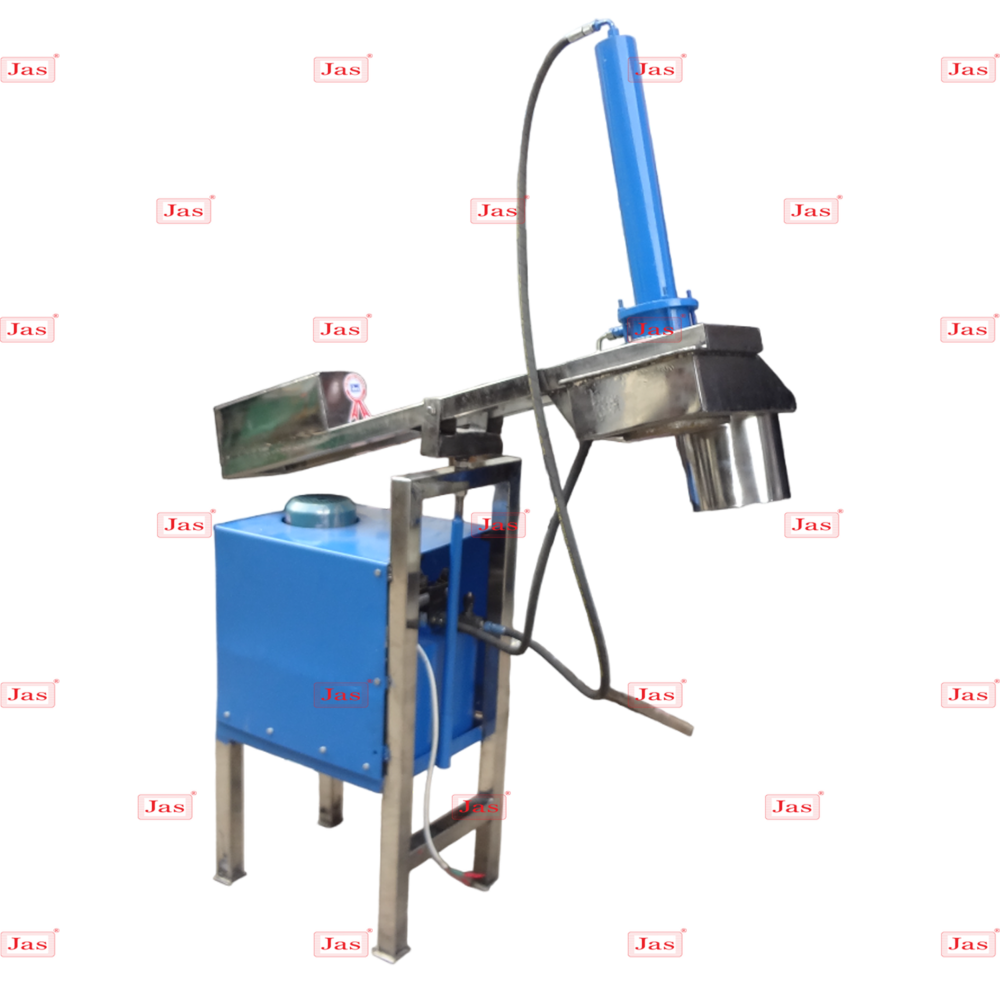

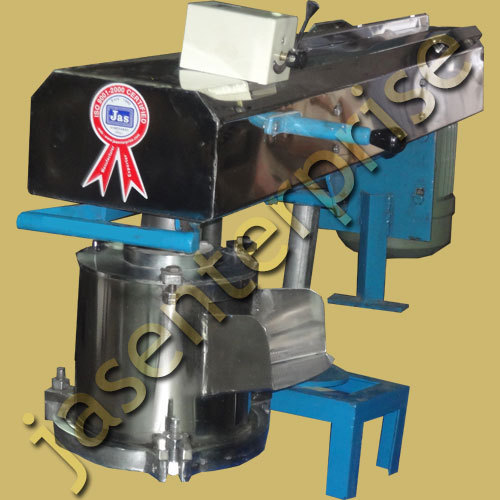

Automatic Namkeen Omapodi Making Machine

Price 100000.00 INR/ Piece

Automatic Namkeen Omapodi Making Machine Specification

- Frequency

- 50-60 Hertz (HZ)

- Phase

- Single Phase / Three Phase

- Automation Grade

- Semi Automatic

- Capacity

- 45-100 Kg/hr

- Voltage

- 230/440 Volt (v)

- Power

- 2-3 Horsepower (HP)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Warranty

- One year against manufacturing defect at our side

Automatic Namkeen Omapodi Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Automatic Namkeen Omapodi Making Machine

The Automatic Namkeen Omapodi Making Machine is an advanced food processing unit specifically engineered for the large-scale and efficient production of omapodi, a traditional South Indian savory snack made from gram flour (besan). Also known as sev or bhujia in various parts of India, omapodi is a staple item in the namkeen industry, and this machine is designed to streamline and automate its production while maintaining authentic taste and texture.

Built with robust stainless-steel construction and food-grade components, the machine offers a hygienic, durable, and corrosion-resistant solution suitable for commercial snack production units. It features an automated dough feeding and extrusion system that shapes the dough into fine strands using specialized dies.

High Efficiency Meets Eco Friendliness

This machine integrates high production rates with an eco-conscious approach. It minimizes energy usage and operates quietly, contributing to a better work environment. Its build quality ensures reliable performance and reduced maintenance, making it a trusted choice for businesses targeting sustainable snack production.

Versatile Installation and Usage

Compact and adaptable, the machine supports both single-phase and three-phase electrical setups. It easily fits into limited spaces, making it suitable for both small shops and larger manufacturing units. Its semi-automatic operation balances ease of use with consistent omapodi quality.

FAQs of Automatic Namkeen Omapodi Making Machine:

Q: How does the Automatic Namkeen Omapodi Making Machine benefit my business operations?

A: This machine boosts efficiency by producing 45-100 kg of omapodi per hour with minimal energy consumption and low noise. Its semi-automatic operation and compact structure allow for easy integration into existing setups, making it ideal for scaling production.Q: What is the process for making omapodi with this machine?

A: Ingredients are loaded into the hopper, and the semi-automatic system extrudes and shapes the omapodi automatically. The user needs to monitor and collect the finished product, ensuring continuous and consistent output due to its high efficiency.Q: When is it necessary to consider the machines warranty and support?

A: The machine comes with a one-year warranty against manufacturing defects. This warranty is applicable from the date of purchase and provides support and repair in case any faults arise due to manufacturing issues.Q: Where can this machine be installed for optimal performance?

A: Its compact design allows installation in limited spaces, such as small shops or larger factory floors. Suitable electrical connections (230/440V, single or three phase) and a stable surface are recommended to ensure safe and efficient operation.Q: What are the main benefits of the machines eco-friendly and low noise features?

A: It substantially lowers energy consumption, reducing operating costs and environmental impact. The low noise output creates a more comfortable workplace, making it ideal for urban or residential manufacturing areas.Q: How does the machines automation grade affect its usage?

A: Being semi-automatic, the machine simplifies the production process while requiring minimal manual intervention. Operators can focus on overseeing production and quality control, enhancing both productivity and consistency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

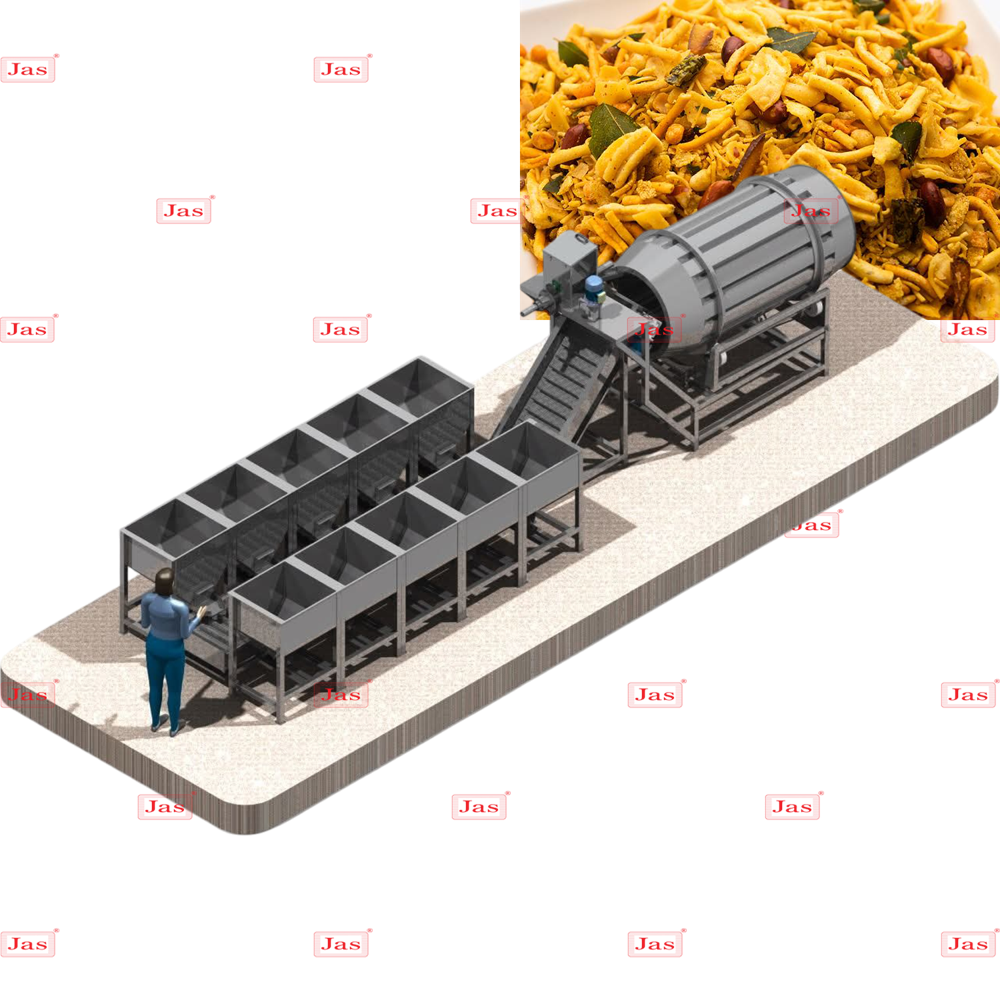

More Products in Namkeen Making Machine Category

Namkeen Mixture Making Machine

Price Range 50000.00 - 125000.00 INR / Unit

Minimum Order Quantity : 01 Unit

Automatic : Yes

Capacity : 300600 Kg/hr

Feature : Other, High Efficiency, Rust Proof, Easy To Operate

Farsan Machine

Price Range 22000.00 - 65000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Capacity : 25200 Kg/hr

Feature : Lower Energy Consumption, ECO Friendly, High Efficiency, Low Noice, Compact Structure

Industrial Online Namkeen Mixer Machine

Price 400000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Capacity : 500 Kg/hr

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Dal Washer

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free