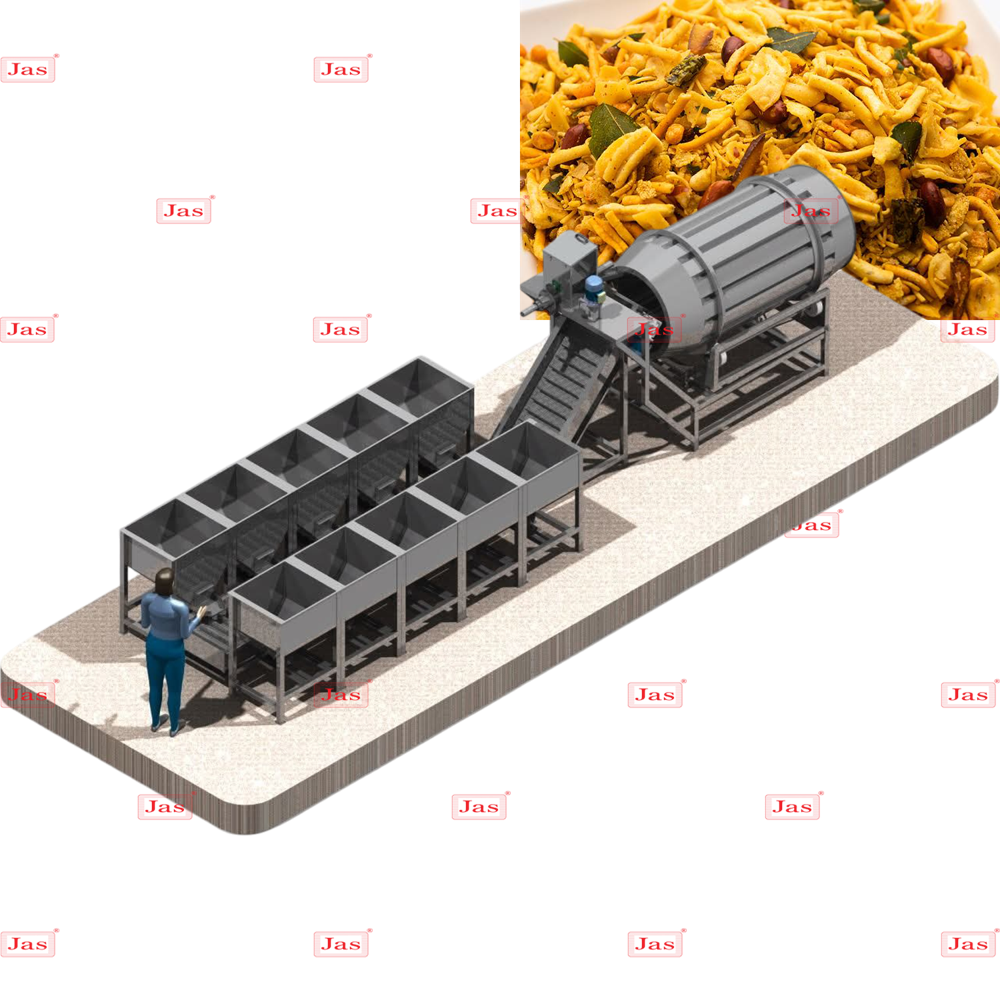

Industrial Online Namkeen Mixer Machine

Price 400000.0 INR/ Unit

Industrial Online Namkeen Mixer Machine Specification

- Speed Mode

- Variable

- Noise Level

- 85 db

- Frequency

- 50 Hertz (HZ)

- Phase

- 3 Phase

- Capacity

- 500 Kg/hr

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Installation Type

- Free Stand

- Voltage

- 415-440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Warranty

- 1 Year against Manufacturing Defect

Industrial Online Namkeen Mixer Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 4 Week

About Industrial Online Namkeen Mixer Machine

High-Efficiency Industrial Namkeen Mixer MachineOur Industrial Namkeen Mixer Machine is designed for snack manufacturers who refuse to compromise on taste and consistency. Whether you are making Bhujia, Sev, Chivda, or Gathiya, this machine ensures every single piece is perfectly coated with spices.

Why Choose Our Industrial Mixer?

-

Uniform Coating: Achieve 98% coating consistency, eliminating "dry spots" and ensuring the same great taste in every packet.

-

Reduced Breakage: Engineered with a gentle tumbling mechanism (24-36 RPM) to protect delicate snacks from crumbling.

-

Food-Grade Hygiene: Built with SS 304/316 Stainless Steel, meeting all FSSAI and global food safety standards.

-

High ROI: Lower your labor costs and reduce masala wastage by up to 15% per batch.

-

Versatile Design: Features an easy-tilting drum for quick discharge and cleaning.

Advanced Automation for Precision Mixing

Utilizing a state-of-the-art PLC control system, the Industrial Namkeen Mixer Machine delivers highly consistent results with every batch. The computerized features allow operators to easily program and monitor the process, ensuring uniform mixing while reducing human error and enhancing product quality. Its variable speed options further provide adaptability for different recipes.

Energy-Efficient and Eco-Friendly Design

Engineered with sustainability in mind, this mixer minimizes electricity consumption without sacrificing performance. Its compact structure also helps conserve valuable floor space in your production facility, while the low noise level ensures a more comfortable work environment.

User-Friendly Installation and Operation

Ready to use with a free-stand installation type, the mixer is designed for straightforward setup and easy integration into existing production lines. Its automated operation reduces manual labor and overall operational costs, supported by a 1-year warranty for added peace of mind.

FAQ's of Industrial Online Namkeen Mixer Machine:

Q: How does the PLC control system benefit the namkeen mixing process?

A: The PLC (Programmable Logic Controller) system ensures precise, automated control over mixing parameters, leading to uniform product quality and reduced chances of manual error. This advanced system improves process reliability and allows for easy monitoring and adjustments.Q: What capacity and speed options are available for this mixer?

A: The machine has a high mixing capacity of 500 kg per hour and offers variable speed modes. This enables users to tailor the mixing process according to different batch sizes and recipe requirements, enhancing operational flexibility.Q: Where can this industrial mixer be installed in a production facility?

A: Thanks to its compact and free-stand installation design, the mixer can be conveniently placed on the production floor without requiring extensive modifications. Its structure allows for easy integration into both new and existing lines.Q: When should maintenance and servicing be performed on this machine?

A: Routine maintenance should be carried out as per the manufacturer's recommendations to ensure optimal performance and longevity. The machine also comes with a 1-year warranty against manufacturing defects, providing additional support during early use.Q: What makes the mixer eco-friendly and energy-efficient?

A: The mixer is engineered to operate with lower energy consumption and reduced noise levels (85 dB). This, along with its efficient design, minimizes the environmental footprint and operating costs for large-scale food processing businesses.Q: How can users operate and monitor the machine's computerized features?

A: Operators can easily manage and monitor the mixer using its user-friendly computerized interface, which allows for programming, real-time adjustments, and tracking of key operating parameters during the production process.Q: What are the primary benefits of choosing this mixer for industrial food processing?

A: Key benefits include high efficiency, precise and automatic control, eco-friendly operation, low noise, energy savings, and a robust warranty period. These features provide consistent product quality and help lower overall production costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Namkeen Making Machine Category

Namkeen Mixture Making Machine

Price Range 50000.00 - 125000.00 INR / Unit

Minimum Order Quantity : 01 Unit

Material : Stainless Steel

Automatic : Yes

Capacity : 300600 Kg/hr

Computerized : No

Rectangular Batch Fryers

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Automatic : Other, Semi Automatic

Capacity : 100500 kg/hr

Computerized : No

Namkeen Farsan Mixer Machines

Price Range 45000.00 - 135000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Automatic : No

Capacity : 50 to 100 Kg/hr

Computerized : No

Nylon Sev Making Machine Farsan Machine

Price Range 22000.00 - 80000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Automatic : No

Capacity : 10 to 100 Kg/hr

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS