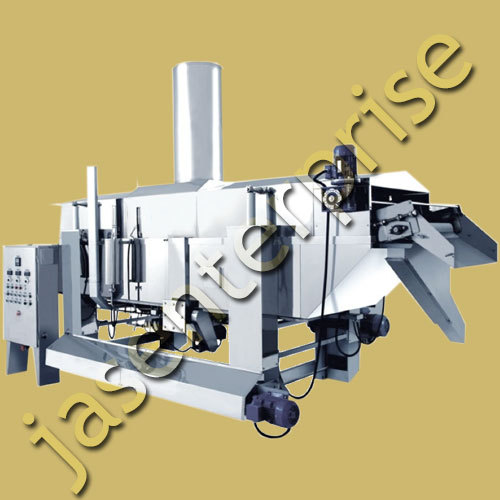

Rectangular Batch Fryers

Price 50000 INR/ Unit

Rectangular Batch Fryers Specification

- Speed Mode

- Variable

- Power Source

- Electric

- Noise Level

- Low

- Operating Temperature

- 150C - 220C

- Function Type

- Frying

- Frequency

- 50/60 Hz

- Automation Grade

- Semi Automatic

- Feeding System

- Manual

- Heating Method

- Diesel/Gas/Electric

- Machine Type

- Food Processing Machinery

- Features

- Oil Filtration, High Thermal Efficiency

- Phase

- Three Phase

- Product Type

- Batch Fryer

- General Use

- Industrial Food Frying

- Material

- Stainless Steel

- Type

- Batch Fryer

- Capacity

- 100-500 kg/hr

- Weight (kg)

- 300 kg

- Product Shape

- Rectangular

- Computerized

- No

- Automatic

- Semi Automatic

- Control System

- Manual/Pneumatic

- Installation Type

- Free Standing

- Voltage

- 220-380 V

- Power

- 250 Watt (w)

- Dimension (L*W*H)

- 152.4 x 66.04 Millimeter (mm)

- Raw Material

- Stainless Steel

- Feature

- Corrosion Resistant, High Efficiency, Easy Operation

- Color

- Silver

Rectangular Batch Fryers Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Months

About Rectangular Batch Fryers

We hold expertise in offering supreme quality Rectangular Batch Fryers. The fryers are are mounted on a stainless steel performance for sturdy construction and stable performance. These fryers are fitted with a pan with and inlet and outlet for the flow of oil. The pan is insulated from the bottom to prevent heat loss and improve performance. Furthermore, we offer these Rectangular Batch Fryers with a digital temperature controller and control panel for adjusting the temperature and adjust the functionality.

Features:

- Longer service life

- Low maintenance

- Sturdy construction

Other details:

Rectangular Batch Fryers with Inbuilt Heat Exchanger

Rectangular frying system is fabricated in stainless steel body having pan is mounted on a stainless steel body. The pan is having multiple opening for oil inlet from one side and outlet from the other side, the flow of oil is regulated by an oil circulating pump. The heated oil in the pan is coming from the heat exchanger and going out into the bucket type filter from the side of the pan. The pan is properly insulated from the bottom to avoid heat loss. Continuous bucket types filter for filtering the edible oil continuously. The frying system is connected with Digital Temperature Controller and Control Panel. The unique feature of this fryer is its tilting system that enables unloading of products in a single stroke after frying for uniform and consistent product quality.

|

Products |

Production Capacity |

Fuel Consumption |

|

Chana Dal |

100-110 Kg/Hour |

11-12 litters/Hour |

|

Moong Dal |

90-95 Kg/Hour |

11-12 litters/Hour |

|

Banana chips |

50- 55 Kg/Hour |

11-12 litters/Hour |

|

Potato Chips |

50-55 Kg/Hour |

11-12 litters/Hour |

Exceptional Performance and Efficiency

Our batch fryer offers high efficiency and supports an oil holding capacity of 150 liters, making it apt for industrial use. With adjustable frying times and variable speed modes, it ensures precise results, accommodating diverse frying requirements with ease and speed.

Advanced Safety and User-Friendly Operation

Equipped with overheat protection and emergency stop features, the fryer prioritizes user safety. Heavy-duty castor wheels allow easy mobility, while the manual ball type oil drain valve and easy-open cleaning system streamline maintenance and promote safe operation.

Durable Construction and Corrosion Resistance

Constructed from polished stainless steel, this batch fryer resists corrosion and maintains hygiene. The heavy gauge SS basket with perforated divider design ensures even frying, simplifies cleaning, and withstands rigorous daily use in demanding industrial environments.

FAQs of Rectangular Batch Fryers:

Q: How do I operate the Rectangular Batch Fryer for optimal frying results?

A: To achieve optimal frying results, load the food into the heavy gauge stainless steel perforated basket, set the desired frying temperature (between 150C and 220C), and adjust the variable speed mode as needed. Monitor the batch for 515 minutes, depending on your recipe, and use the manual pneumatic controls to operate the system efficiently.Q: What safety features are included in this batch fryer?

A: This fryer is equipped with overheat protection and an emergency stop button to safeguard users during operation. These features help prevent accidents and ensure safe functioning, even during high-volume industrial use.Q: When and how should I clean the fryer?

A: For best results, clean the fryer after each production cycle by opening the easy-access drain valve. Ensure the unit is off and cooled before draining the oil. The polished stainless steel surface and removable perforated baskets simplify cleaning and maintenance.Q: Where can the Rectangular Batch Fryer be installed and used?

A: Designed as a free-standing unit, this fryer is suitable for installation in industrial kitchens, food processing plants, and commercial frying facilities across India. Heavy-duty castor wheels make it easy to move and position as needed.Q: What is the frying process using the manual feeding system?

A: Food items are manually placed into the perforated divider-type baskets. After setting operational parameters, the batch fries for 515 minutes. The manual feeding system offers precise control over batch size and timing, supporting consistent results batch after batch.Q: What benefits does the polished stainless steel construction provide?

A: Polished stainless steel ensures superior durability, corrosion resistance, and ease of cleaning. This material maintains food hygiene standards and withstands continuous use, making the fryer reliable for long-term industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Namkeen Making Machine Category

continuous namkeen fryer

Price 50000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 415 Volt (v)

Capacity : 325 350 Kg/hr

Feature : Other, Energy Efficient, Corrosion Resistant, Low Maintenance

Namkeen Mixture Making Machine

Price Range 50000.00 - 125000.00 INR / Unit

Minimum Order Quantity : 01 Unit

Voltage : 220240V

Capacity : 300600 Kg/hr

Feature : Other, High Efficiency, Rust Proof, Easy To Operate

Farsan Making Machine

Price 22000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Capacity : 25200 Kg/hr

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Tilting Type Centrifuge

Price Range 25000.00 - 125000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110440 Volt (v)

Capacity : 7 to 60 Kg/Batch Kg/day

Feature : Lower Energy Consumption, High Efficiency, ECO Friendly, Low Noice, Compact Structure

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free