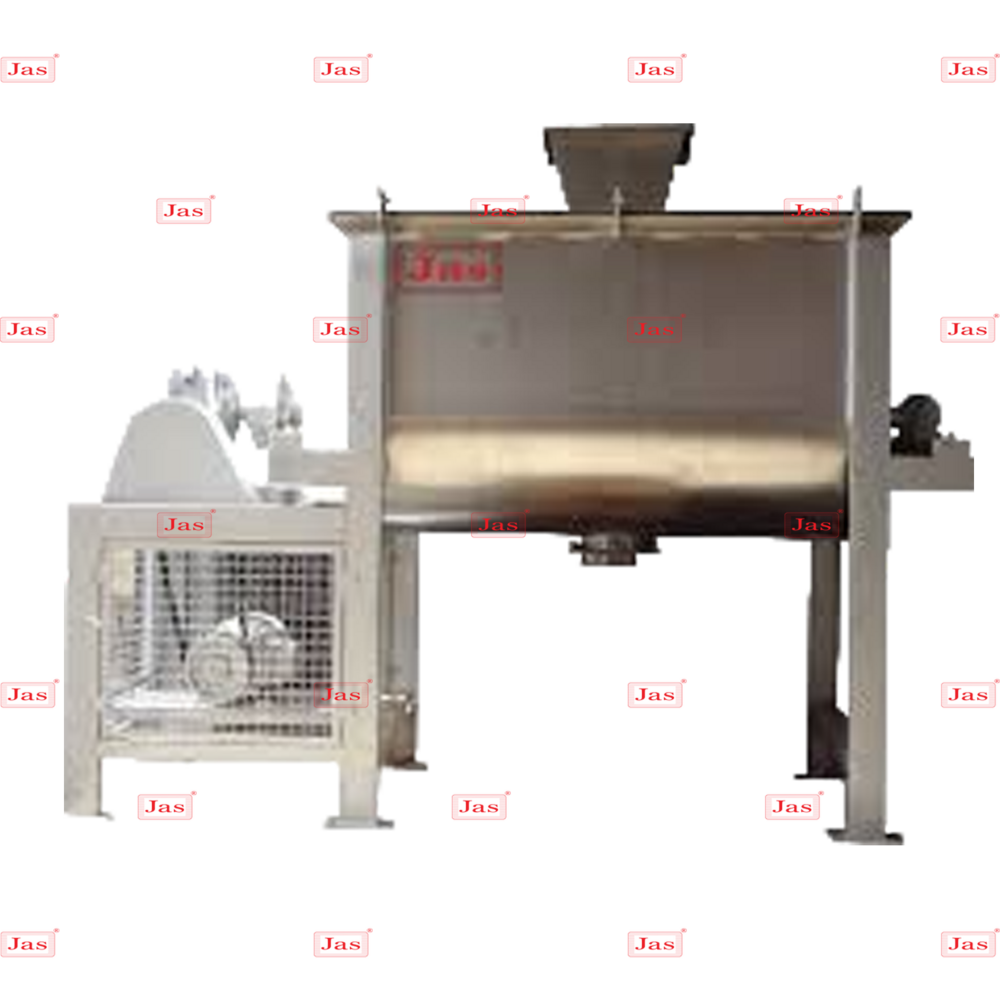

Blending Machines

Price 65000.00 INR/ Piece

Blending Machines Specification

- Frequency

- 50-60 Hertz (HZ)

- Automation Grade

- Semi Automatic

- Phase

- Single Phase / Three Phase

- Capacity

- 10-1000 kg/betch Kg

- Voltage

- 230/440 Volt (v)

- Power

- 1-15 Horsepower (HP)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Warranty

- One year against manufacturing defect at our side

Blending Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Blending Machines

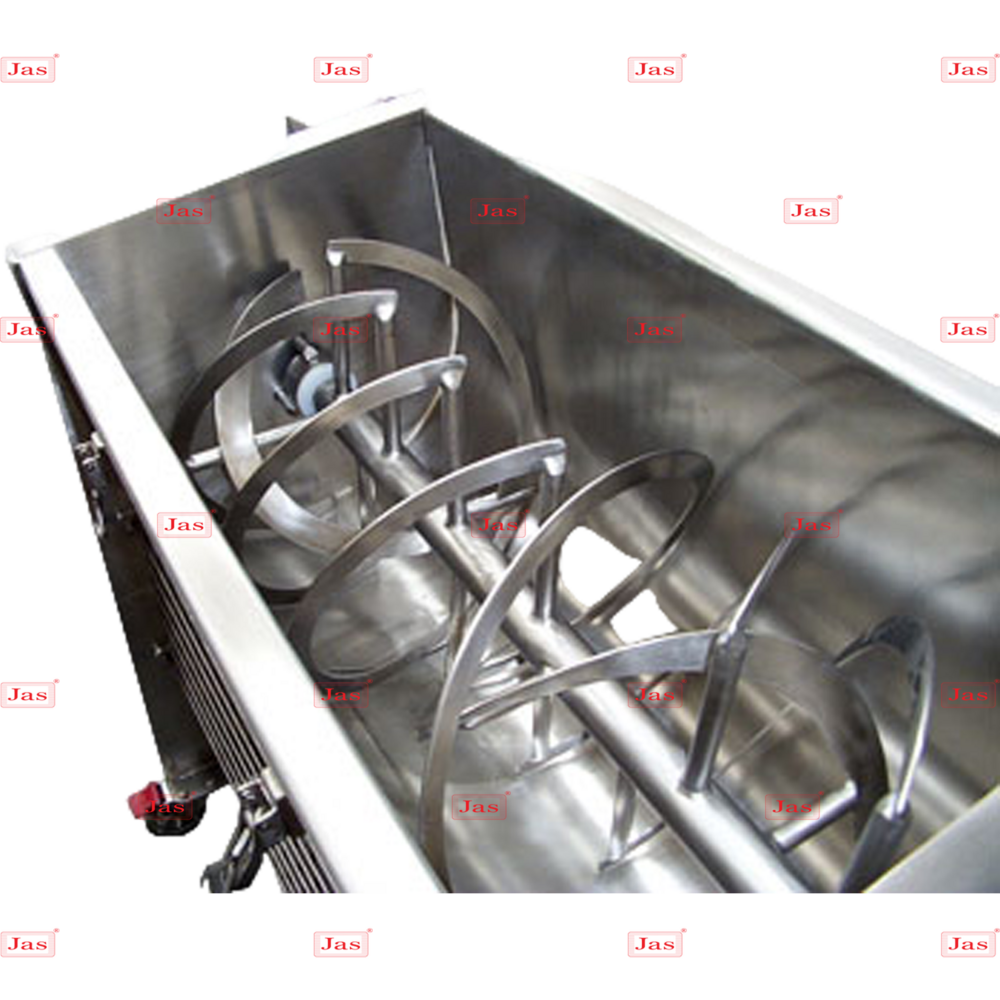

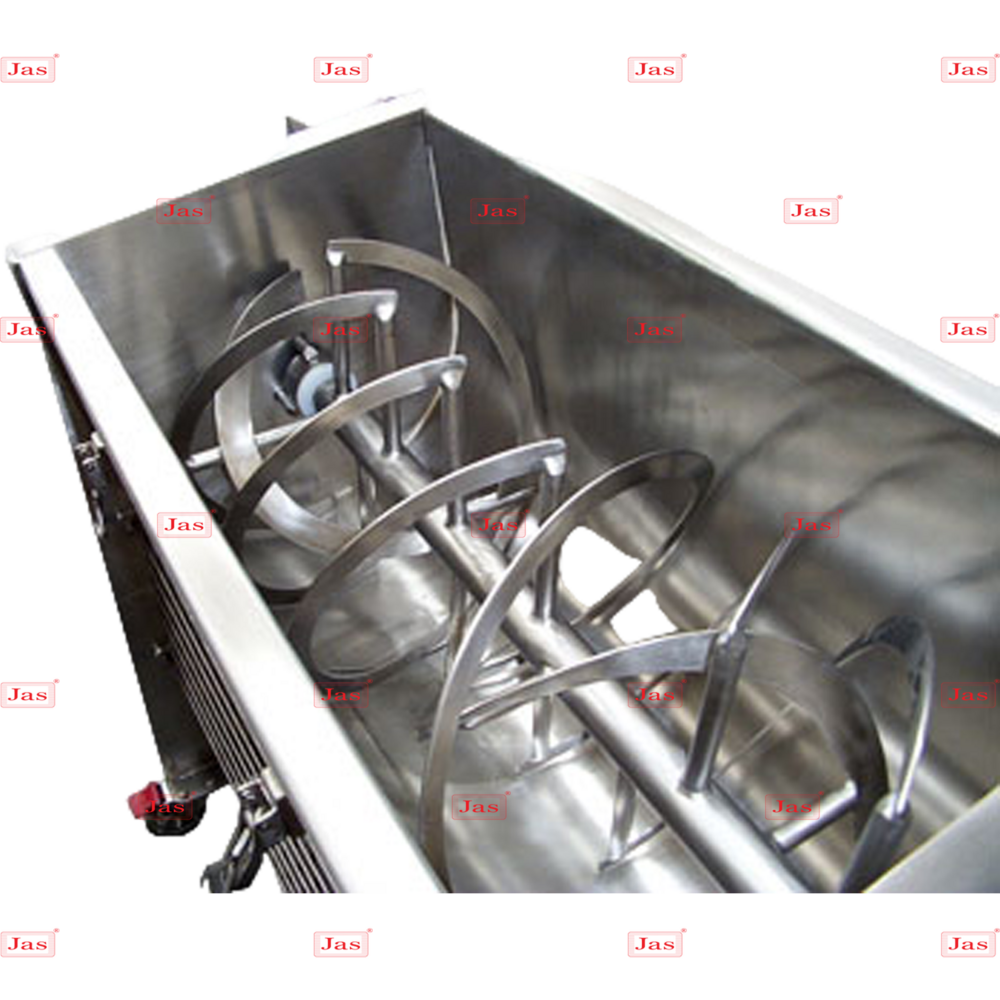

Blending machines are industrial equipment designed to mix, homogenize, or combine multiple components into a consistent and uniform mixture. These machines are essential in a wide range of industries, including food and beverage, pharmaceuticals, chemicals, plastics, cosmetics, and construction materials. Their primary function is to ensure even distribution of ingredients, whether solid-solid, solid-liquid, or liquid-liquid, depending on the process requirements.

Eco-conscious Innovation

The blending machines embody environmental responsibility by integrating low energy consumption and minimal noise emissions. This not only supports sustainability efforts but also provides a healthier workspace environment for operators. Compact structure ensures optimal use of floor space, making them versatile for small to large production facilities.

Exceptional Efficiency and Versatility

Engineered for high efficiency, these semi-automatic blending machines are suitable for various mix sizes, accommodating batches from 10 to 1000 kg. Whether powered by single or three-phase electricity, their wide voltage compatibility and horsepower range make them ideal for diverse industrial blending needs across India.

Warranty and Support Assurance

Every machine comes with a comprehensive one-year warranty against manufacturing defects, giving customers confidence in durability and post-purchase support. Our network of distributors, manufacturers, and service partners ensures reliable after-sales customer assistance throughout India.

FAQs of Blending Machines:

Q: How do I choose between single phase and three phase blending machines for my facility?

A: Select the phase type based on your facilitys electrical access. Single phase machines (230V) are suitable for smaller operations, while three phase models (440V) are ideal for larger industries requiring higher power and efficiency.Q: What batch capacity options are available, and how do I determine the right size for my process?

A: Batch capacities range from 10 to 1000 kg per batch. Assess your production volume and process requirements to choose a size that optimizes workflow without exceeding available space or resources.Q: When should I perform routine maintenance on the blending machine?

A: Regular maintenance should be scheduled monthly or according to the usage intensity, ensuring longevity and consistent high-efficiency performance. Always consult the user manual for model-specific recommendations.Q: Where can I purchase or service these blending machines in India?

A: These machines are available through a comprehensive network of distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers throughout India. Service and support are provided at authorized centers nationwide.Q: What process steps does the semi-automatic blending machine require during operation?

A: Users need to load materials, set desired parameters (capacity, time, etc.), and initiate the blending cycle. The semi-automatic system manages the mixing, but manual oversight ensures quality and prevents overloading.Q: How does the eco-friendly design of the machine benefit my operation?

A: The eco-friendly design features lower energy consumption and reduced noise levels, which not only decreases operational costs but also improves the working environment and aligns with sustainability goals.Q: What are the warranty terms, and what do they cover?

A: Each blending machine includes a one-year warranty against manufacturing defects, covering repairs and replacements for issues resulting from faulty workmanship or materials as determined by the manufacturer.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Vegetable Processing Plant

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One year against manufacturing defect at our side

Voltage : 230/440 Volt (v)

Automatic : No

Capacity : 302500 Kg/hr

Flavor Applicators

Price 20000.00-230000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One year against manufacturing defects at our site, except all wear and tear parts.

Voltage : 110 to 440

Automatic : Yes

Capacity : 15 to 180 kg/batch Kg/day

Pulping Plant

Price 36000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One year against manufacturing defects at our site

Voltage : 110 to 440 Volt (v)

Automatic : Yes

Capacity : 502000 Kg/hr

Commercial Atta Chakki Machine

Price 28000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One year against manufacturing defects at our site

Voltage : 110 to 440 Volt (v)

Automatic : Yes

Capacity : 30 to 170 Kg/hr Kg/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free