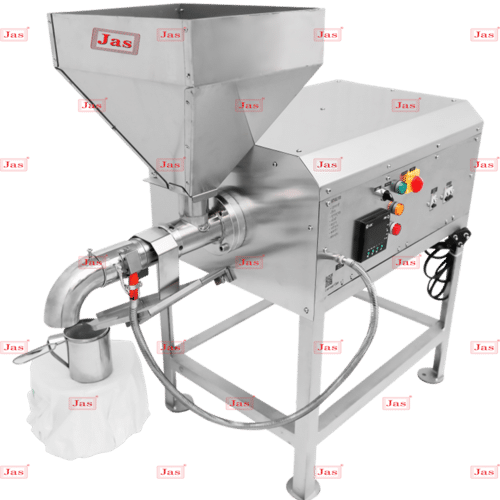

Centrifugal Hydro Extractor

Price 29500 INR/ Unit

Centrifugal Hydro Extractor Specification

- Capacity

- 14-60 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Centrifugal Hydro Extractor Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO 9001

About Centrifugal Hydro Extractor

A centrifugal hydro extractor is a machine designed to remove excess water or moisture from various materials using centrifugal force. Heres a detailed description of its components and functionality:

Components:- Drum/Basket: The central part of the hydro extractor where the material to be dried is placed. It is usually made of perforated stainless steel to allow water to escape.

- Motor: Powers the drum to spin at high speeds, generating centrifugal force.

- Casing: An outer shell that houses the drum and motor, often made of durable materials to withstand high-speed rotations.

- Vibration Dampers: Reduce vibrations and ensure stable operation.

- Control Panel: Provides user control for starting, stopping, and adjusting the speed of the machine.

- Discharge Outlet: Allows the extracted water to be expelled from the machine.

- Safety Features: Includes mechanisms such as automatic shutdown in case of imbalance or overloading to ensure safe operation.

- Loading: The material to be dried is placed inside the drum.

- Spinning: Once the machine is activated, the motor spins the drum at high speeds.

- Centrifugal Force: As the drum spins, centrifugal force pushes the water out of the material towards the walls of the drum.

- Water Extraction: The water escapes through the perforations in the drum and is collected or discharged through the outlet.

- Completion: After a set period or when the desired dryness is achieved, the machine stops, and the dried material can be removed

Superior Performance for Industrial Applications

With its automatic feature and robust centrifugal action, this hydro extractor is crafted to deliver repeatable results in demanding environments. Its energy-saving design ensures optimal water removal with minimal consumption, making it suitable for small and large businesses alike. Its eco-friendly construction reduces operational impact, delivering reliable efficiency without sacrificing sustainability.

Flexible Installation & Operation

Thanks to its compact structure and choice between 230V and 440V voltage, this extractor is easy to install in various settings. Whether upgrading existing facilities or building new ones, integrating this machine streamlines overall workflows. The user-friendly controls further simplify daily operations, allowing teams to focus on productivity and quality.

FAQs of Centrifugal Hydro Extractor:

Q: How does the Centrifugal Hydro Extractor achieve high efficiency with low energy consumption?

A: The extractor utilizes advanced centrifugal force to rapidly remove excess water, requiring less energy per batch. Its automatic operation streamlines the process, minimizing manual intervention and conserving energy while delivering quick, efficient extraction.Q: What capacity options are available for this hydro extractor?

A: This model supports capacities ranging from 14 to 60 Kg/hr, making it suitable for various scales of production, from small operations to larger industrial applications.Q: Where can the Centrifugal Hydro Extractor be installed and used?

A: Its compact structure and adaptable voltage options (230/440 Volt) make it easy to install in a wide range of settings, including laundries, textile factories, and other industrial environments across India.Q: What are the main benefits of using this hydro extractor in my facility?

A: The primary benefits include lower noise levels, reduced energy consumption, high operational efficiency, eco-friendly performance, and a space-saving design, all contributing to better productivity and lower operational costs.Q: How is the extractor supplied and by whom in India?

A: This hydro extractor is distributed, exported, manufactured, supplied, and retailed by a network of reputable partners across India, including traders and wholesalers, ensuring accessibility and reliable after-sales support for customers.Q: What is the process for operating the automatic hydro extractor?

A: To operate, users simply load the material, set the required parameters on the user-friendly interface, and start the machine. The automatic system manages the extraction process, stopping once the cycle completes, thereby simplifying operation and saving time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Oil Mill, Oil Extraction Machinery & Equipment Category

Wooden Press Oil Extraction Machine

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Voltage : 230 Volts Volt (v)

Automatic : No

Oil Processing Machinery

Price 16000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Voltage : 230/440 Volt (v)

Automatic : Yes

Capacity : 225 Kg/hr

Oil Mill Oil Extraction Machinery and Equipment

Price 20000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Lower Energy Consumption, ECO Friendly, High Efficiency, Low Noice, Compact Structure

Voltage : 110 to 440 Horsepower (HP)

Automatic : Yes

Capacity : 8 Kg/hr

Commercial Automatic Copra Cutter

Price 11000 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, High Efficiency

Voltage : 110415 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free