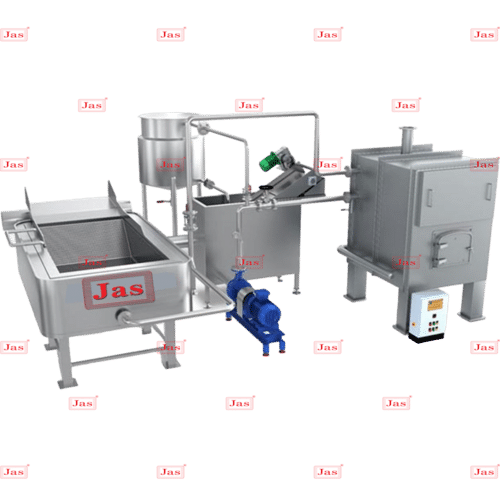

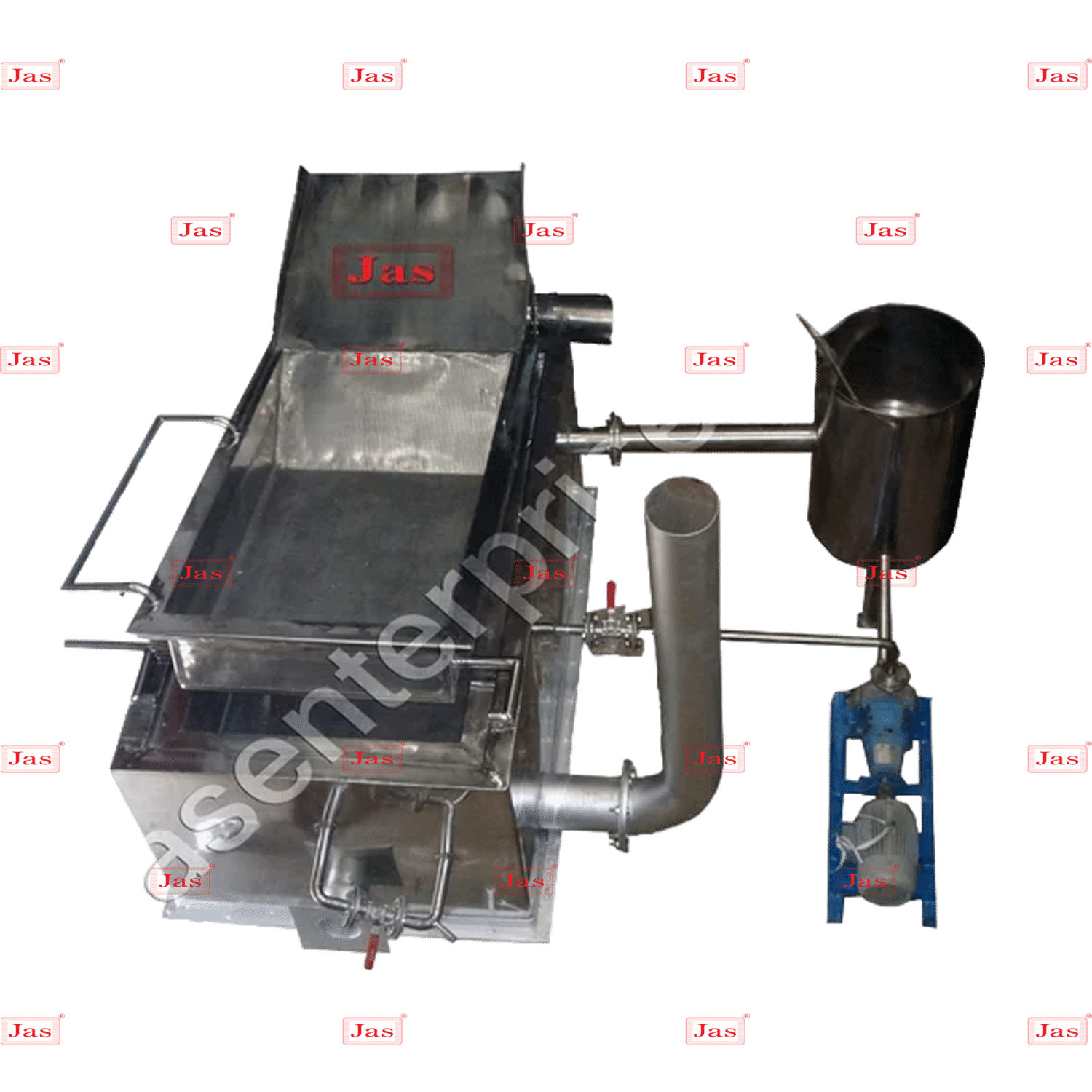

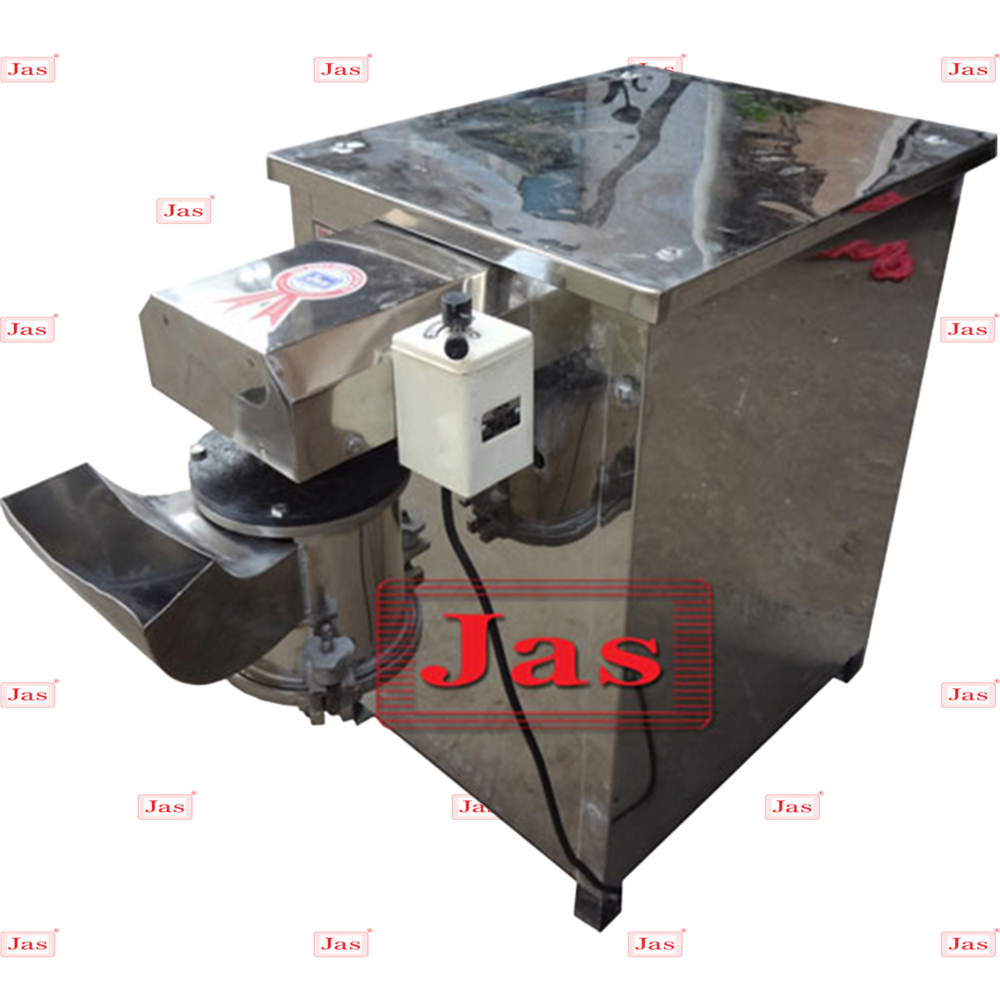

Diesel Batch Fryer

Price 10500 INR/ Unit

Diesel Batch Fryer Specification

- Capacity

- 12-32 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Diesel Batch Fryer Trade Information

- Minimum Order Quantity

- 1 Unit

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Diesel Batch Fryer

-

Feeder System This component is responsible for feeding raw fruits into the machine It often includes conveyors or hoppers to ensure a steady flow

Slicing Mechanism This part slices the fruit into thin uniform chips It can use sharp blades or cutting rollers to achieve the desired thickness

Drying Chamber After slicing the fruit chips are dried to remove moisture Drying methods can vary

Hot Air Drying Uses hot air to evaporate moisture

Freeze Drying Involves freezing the fruit and then removing the ice through sublimation

Dehydration Employs heat and airflow to dry the fruit

Cooling System Once dried the chips need to be cooled before packaging to prevent moisture absorption and ensure freshness

Packaging Unit Some machines come with an integrated packaging system to seal the chips in bags or containers

Control Panel Allows operators to set parameters like temperature drying time and slicing thickness

Versatile and Robust Performance

Engineered to accommodate capacities from 12 to 32 kg/hr, this fryer can handle varying production demands with ease. Its automatic controls streamline the frying process, ensuring consistency and safety during operation. Reliable voltage adaptability (230/440V) allows deployment in diverse industrial settings.

Eco-Friendly and Cost-Effective

The fryer is designed with environmental responsibility in mind, utilizing fuel-efficient diesel technology to lower operational costs. Its compact structure conserves valuable kitchen space, while its low-energy consumption and minimal noise enhance workplace comfort and sustainability.

FAQs of Diesel Batch Fryer:

Q: How does the automatic feature in the Diesel Batch Fryer enhance the frying process?

A: The automatic function regulates temperature and frying time, ensuring each batch is fried to perfection with minimal manual intervention. This leads to consistent results, improved safety, and reduced labor requirements, making the process efficient and reliable.Q: What are the primary benefits of using this Diesel Batch Fryer for commercial purposes?

A: Key benefits include high efficiency, lower energy consumption, eco-friendly operation, and compact design. The fryer produces minimal noise, ensuring a better work environment, and supports significant batch capacities, making it ideal for busy commercial kitchens.Q: When is the Diesel Batch Fryer most suitable for use in food production?

A: This fryer is best suited for medium to large-scale operations where consistent output, energy savings, and reliable performance are required. It is particularly valuable during peak production periods due to its high throughput and automation.Q: Where can I purchase or source this Diesel Batch Fryer in India?

A: The fryer is available through various distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers throughout India. You can reach out to established industry suppliers for efficient procurement and after-sales support.Q: What is the process for operating the Diesel Batch Fryer safely and efficiently?

A: To operate the fryer, connect it to a compatible voltage source (230/440V), load the frying basket, and set the automatic controls. The machine manages the frying cycle, requiring only basic supervision. Regular cleaning and maintenance ensure consistent high performance.Q: How does the eco-friendly aspect of the fryer benefit my business?

A: Its eco-friendly design minimizes environmental impact by reducing diesel consumption and emissions. Lower energy usage translates into cost savings over time, aligning your business with sustainable operational practices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

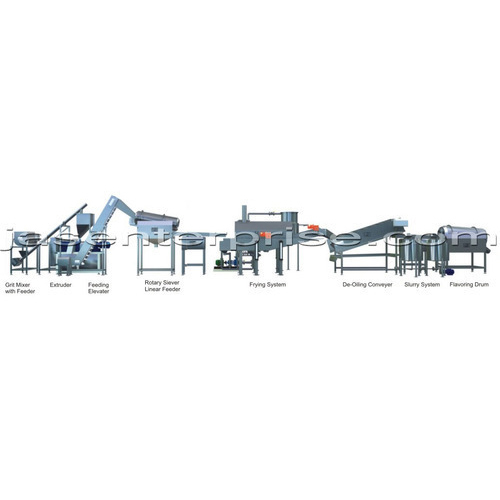

Fully Automatic Corn Curls Kurkure Production Line

Minimum Order Quantity : 1 Unit

Voltage : 440 Volt (v)

Capacity : 100 TO 300 Kg/hr

Power : 5 to 20 Horsepower (HP)

Curd Churner Machine

Price 1590 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230 Volt (v)

Capacity : 50200 liter Ltr

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Power : 0.51 Horsepower (HP)

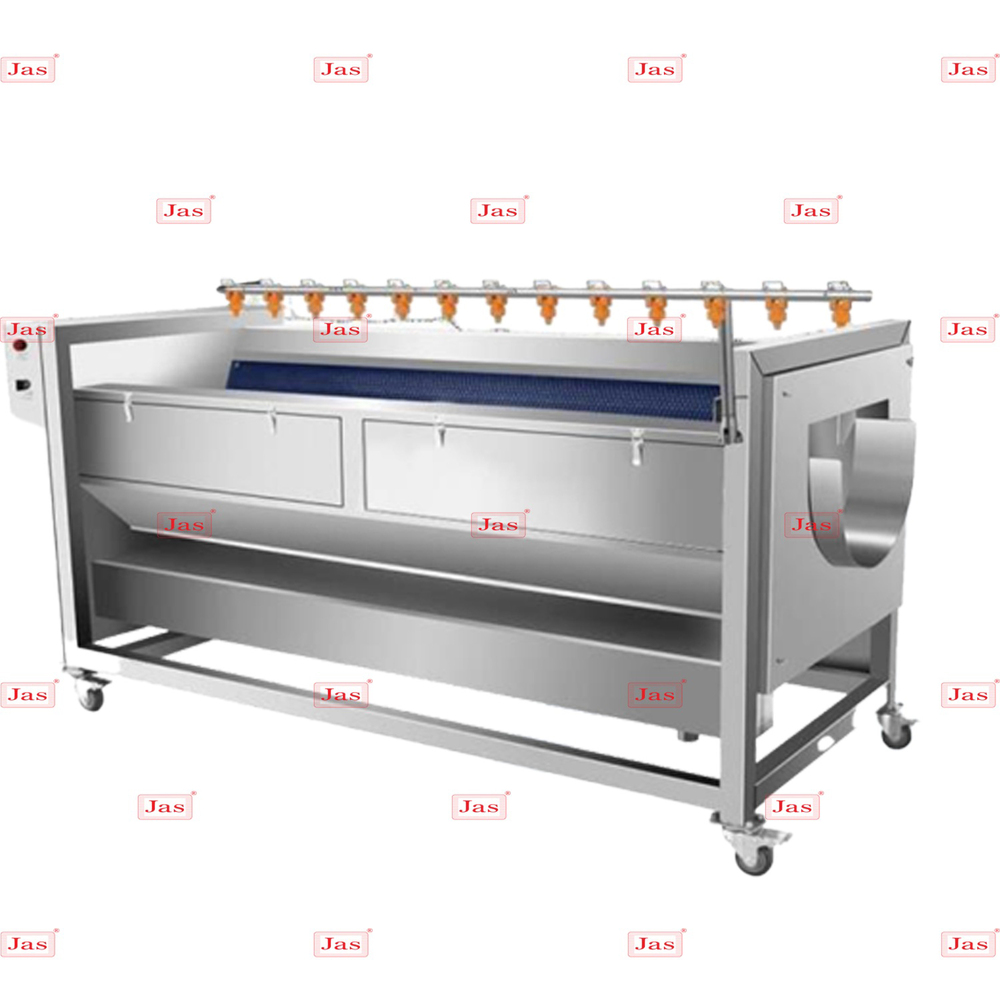

Industrial Vegetable Washing Machine

Price 615000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 440 Volt (v)

Capacity : 200 Kg/hr

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Power : 515 Horsepower (HP)

Wheat Kurdai Machine Rice Kurdai Machine

Price 50000 INR / Piece

Minimum Order Quantity : 1 Unit

Voltage : 230 Volt (v)

Capacity : 4045 Kg/hr

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Power : 1 Horsepower (HP)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS