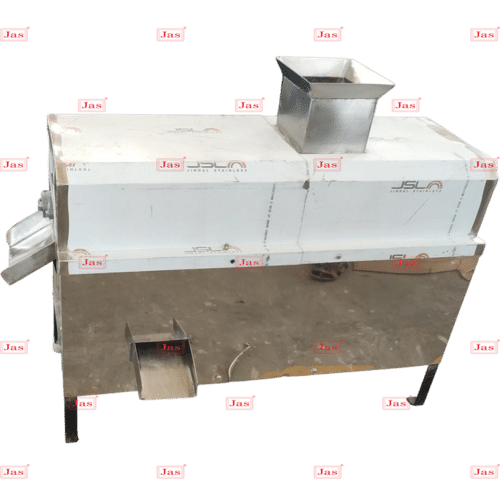

Dumpling Wrapper Making Machine

Price 40000 INR/ Unit

Dumpling Wrapper Making Machine Specification

- Frequency

- 50-60 Hertz (HZ)

- Automation Grade

- Semi Automatic

- Phase

- Single Phase

- General Use

- Industrial

- Material

- Stainless Steel

- Capacity

- 300-11000 Pcs/hr

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Voltage

- 230 Volt (v)

- Power

- 0.5-2 Horsepower (HP)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Warranty

- One year against manufacturing defect at our side

Dumpling Wrapper Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Dumpling Wrapper Making Machine

The Dumpling Wrapper Making Machine is a state-of-the-art food processing solution engineered to meet the growing demand for fast, consistent, and hygienic production of dumpling wrappers. Designed for use in commercial kitchens, central kitchens, food processing factories, and frozen food manufacturing plants, this machine automates the otherwise labor-intensive task of rolling and cutting dough into precise dumpling wrapper shapes.

Built with efficiency and food safety in mind, the machine delivers unmatched speed and uniformity, producing hundreds to thousands of wrappers per hour. Whether you are producing traditional Chinese dumplings, potstickers, wontons, or even wrappers for fusion or international stuffed foods like samosas and empanadas, this machine ensures consistent results every time.

Sturdy Industrial Performance

Manufactured using durable stainless steel and optimized for industrial applications, this semi-automatic dumpling wrapper machine delivers reliable performance, even in demanding environments. Its manual control system allows operators to easily manage the process for consistently high-quality output.

Efficient and Eco-Friendly Design

This machine is engineered to enhance productivity and sustainability. By minimizing noise and energy consumption while maximizing capacity, businesses can meet large production demands without compromising on environmental responsibility.

Compact and User-Friendly

The compact structure allows for easy installation in various industrial settings, making the most of available workspace. Despite its robust capacity, the machine is straightforward to operate, even for users without extensive technical experience.

FAQ's of Dumpling Wrapper Making Machine:

Q: How does the manual control system benefit the operation of the dumpling wrapper making machine?

A: The manual control system gives operators direct oversight of the production process, allowing for better handling and customization during operation. This enables efficient management of different wrapper sizes and thicknesses based on specific requirements.Q: What is the production capacity of this dumpling wrapper machine?

A: This semi-automatic machine is capable of producing between 300 and 11,000 pieces per hour, making it suitable for a variety of scales in industrial dumpling production.Q: When should the machine be serviced to maintain optimal performance?

A: Routine cleaning and basic maintenance after daily operation are recommended, with more thorough servicing every few months or as advised in the user manual to ensure continued efficiency and prevent downtime.Q: Where can this dumpling wrapper machine be installed?

A: The compact design allows it to be set up easily in commercial kitchens, food processing units, or factory production lines. The single-phase, 230 Volt connection makes it compatible with standard industrial electrical systems in India.Q: What steps are involved in the dumpling wrapper making process using this machine?

A: Operators manually load the dough into the machine, adjust settings to the desired thickness and size, then start production. The machine then flattens and cuts the dough into uniform dumpling wrappers, ready for further culinary use.Q: What are the main benefits of using this semi-automatic machine over a fully manual process?

A: It significantly reduces manual labor, increases output speed, and ensures consistency in wrapper size and thickness, all while maintaining low energy costs and operational noise. This results in higher productivity and superior quality control.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Tomato Crusher

Price 33000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Voltage : 230/440 Volt (v)

Capacity : 302600 Kg/hr

Automatic : Yes

Powder Mixers

Price 27000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One year against manufacturing defects at our site

Voltage : 110 to 440 Volt (v)

Capacity : 25 kg Kg/day

Automatic : Yes

Pulping Plant

Price 36000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One year against manufacturing defects at our site

Voltage : 110 to 440 Volt (v)

Capacity : 502000 Kg/hr

Automatic : Yes

Peanut Chikki Making Machine

Price 67500 INR / Piece

Minimum Order Quantity : 1 Unit

Warranty : One year against manufacturing defect at our side

Voltage : 230 Volt (v)

Capacity : 10400 Kg/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free