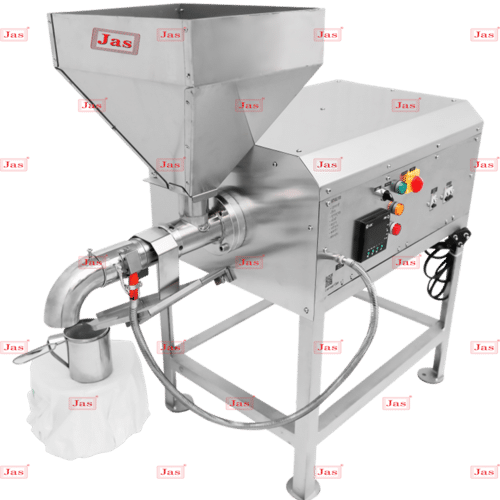

Flaxseed Oil Extraction Machine

MOQ : 1 Unit

Flaxseed Oil Extraction Machine Specification

- Material

- Stainless Steel

- Capacity

- 2 to 20 Kg/hr

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Installation Type

- Table Top

- Warranty

- One year against manufacturing defects at our site, except all wear and tear parts.

Flaxseed Oil Extraction Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 1000 Units Per Month

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, South America, Eastern Europe, Western Europe, Middle East, Asia, Central America, North America, Africa

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Daman and Diu, South India, North India, East India, West India, Assam, Arunachal Pradesh, Bihar, Chhattisgarh, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Maharashtra, Mizoram, Meghalaya, Manipur, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal, Delhi, Gujarat, Madhya Pradesh, Andhra Pradesh, Central India, All India

- Certifications

- ISO 9001

About Flaxseed Oil Extraction Machine

First Indian Manufacturer of Oil Extraction Machine. We have gained remarkable success in India as well as in the global market by producing oil Extraction Machine, Commercial oil maker machine, oil extraction machine, and mini oil Ghani.Advanced Control and Operation

Outfitted with a PLC-controlled, computerized system, this flaxseed oil extraction machine ensures precise, automated performance. Its user-friendly interface and table-top installation maximize ease in both upkeep and operation, making it suitable for businesses prioritizing efficiency.

Versatile Capacity for Various Needs

Boasting a throughput of 2 to 20 kg per hour, this machine is tailored for varied commercial scales. Whether youre processing small batches or larger volumes, it fulfills a wide spectrum of production demands, driving both productivity and business growth.

Quality Construction with Stainless Steel

Constructed from premium stainless steel, the machine resists corrosion and upholds hygiene standards vital for food processing. This guarantees longevity and a reliable, clean extraction process, supporting health-focused production environments.

FAQs of Flaxseed Oil Extraction Machine:

Q: How does the flaxseed oil extraction machine operate automatically?

A: The machine utilizes a PLC control system that enables automated extraction processes. Operators simply set parameters through the computerized interface, allowing the unit to handle pressing, monitoring, and output with minimal manual intervention.Q: What type of material is used in the construction of the machine and why?

A: This machine is made entirely from stainless steel, which provides durability, resists corrosion, and maintains hygienic conditionsan essential consideration for extracting edible oils from flaxseed.Q: When is the ideal time to perform maintenance on the wear and tear parts?

A: Routine inspection is recommended according to the usage frequency and operational hours. While the machine has a one-year warranty for manufacturing defects, regular maintenance of wear and tear parts should be scheduled to maximize efficiency and prevent breakdowns.Q: Where can this flaxseed oil extraction machine be installed?

A: Designed as a table-top unit, it is suitable for installation in processing facilities, commercial kitchens, or any space with adequate support and ventilation. Its compact build allows flexible placement within industrial environments.Q: What is the process involved in extracting oil with this machine?

A: Flaxseed is loaded into the hopper, and with the help of automated pressing mechanisms controlled by the PLC system, oil is extracted, filtered, and collected, while residual cake is automatically separatedall in a seamless cycle.Q: How can businesses benefit from adopting this machine?

A: Businesses gain consistent oil quality, increased production efficiency, and reduced labor costs due to automation. The reliable stainless steel build and support for varying capacities enable adaptation to market demand and scalable growth.Q: Who should consider purchasing this flaxseed oil extraction machine?

A: This equipment is well-suited for distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers throughout India looking to enhance or expand their oil processing capabilities.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Oil Mill, Oil Extraction Machinery & Equipment Category

Wooden Press Oil Extraction Machine

Price Range 71000.00 - 86000.00 / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Automatic : No

Warranty : One year against manufacturing defects at our site, except all wear and tear parts.

Oil Processing Machinery

Price 16000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Automatic : Yes

Warranty : 1 Year

Flex Seed Oil Extraction Machine

Price 20000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Automatic : Yes

Warranty : One year against manufacturing defects at our site

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS