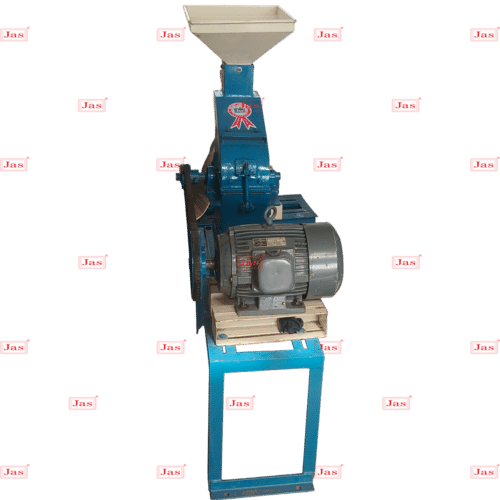

Full Circle Hammer Mill

Price 18000 INR/ Unit

MOQ : 1 Unit

Full Circle Hammer Mill Specification

- Capacity

- 20-2200 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Full Circle Hammer Mill Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Full Circle Hammer Mill

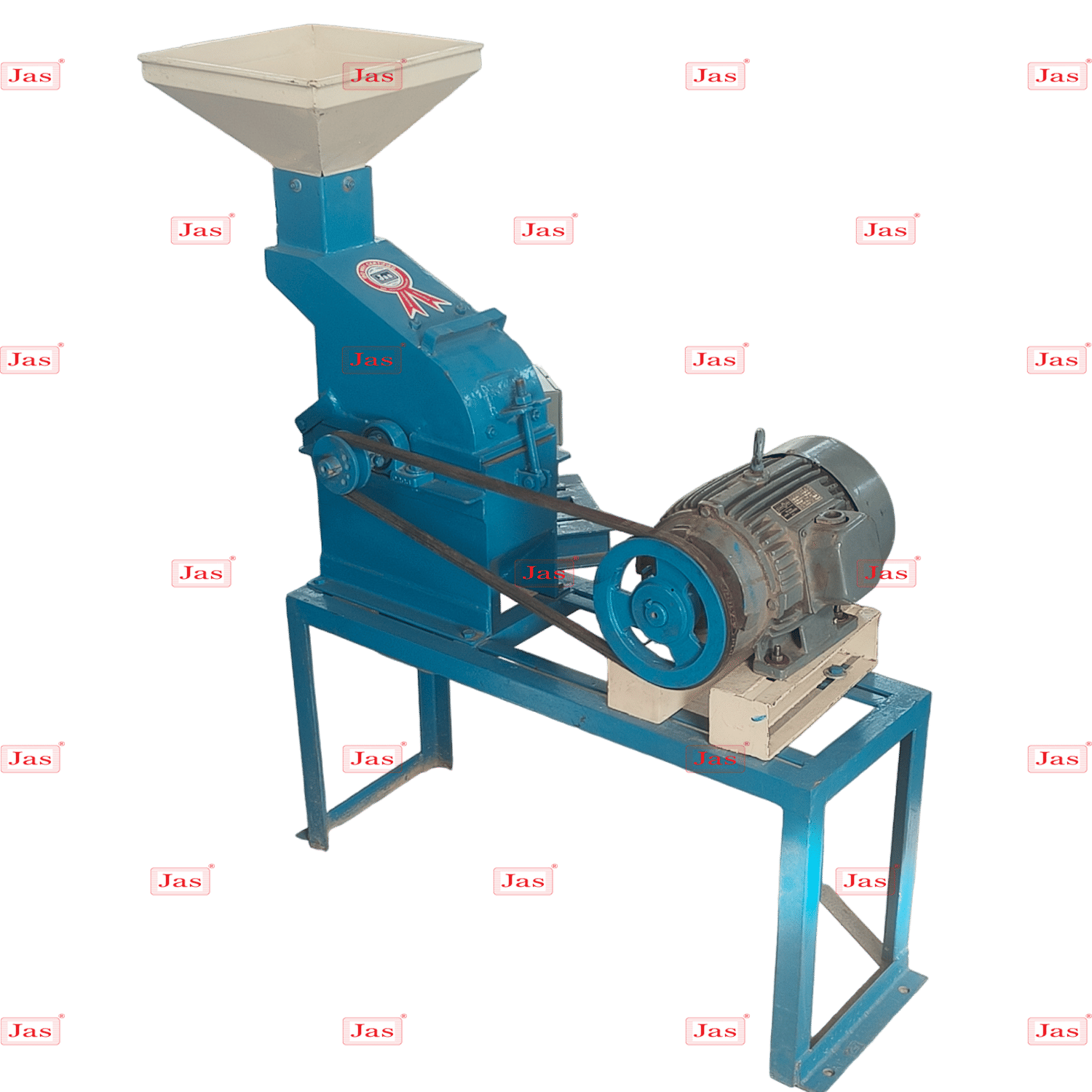

How It Works

Material Feeding Raw materials are fed into the mill through a hopper

Impact Grinding The rotating hammers impact the material breaking it down into smaller particles

Screening The ground material passes through a screen with specific mesh sizes determining the final particle size The screen helps in controlling the fineness of the ground product

Discharge The processed material is then discharged from the mill usually via an outlet

Key Features

Full Circle Design This means the hammers are positioned around the entire circumference of the mill chamber This design helps to ensure a more uniform grind and efficient use of the hammers

Versatility Capable of handling a wide range of materials from grains to wood chips depending on the size and type of the mill

Efficiency The full circle design maximizes the use of the hammers surface area leading to higher efficiency and reduced energy consumption compared to other types of hammer mills

Engineered for Superior Performance

This Full Circle Hammer Mill delivers consistent, high-capacity grinding with minimal noise and low energy demand. Designed for both large-scale and smaller operations, its robust mechanism handles diverse material types efficiently, ensuring optimal throughput for every application. The automatic system reduces manual intervention, improving productivity and workplace safety.

Eco-Friendly and Cost-Efficient Solution

Built with sustainability in mind, the hammer mill utilizes advanced technology to lower energy consumption and decrease operational costs. The reduced noise output helps maintain a comfortable working environment, while its efficient design minimizes environmental impact. This makes it a reliable choice for enterprises keen on ecological responsibility.

FAQs of Full Circle Hammer Mill:

Q: How does the Full Circle Hammer Mill enhance productivity in industrial operations?

A: The Full Circle Hammer Mill is fully automatic and engineered for high efficiency, allowing it to process a wide range of materials swiftly. Its capacity of 20-2200 kg/hr enables continuous operations, while low noise and reduced energy consumption contribute to smoother workflows and operational savings.Q: What are the main benefits of using this hammer mill compared to traditional models?

A: This hammer mill stands out due to its high performance, eco-friendly design, lower energy consumption, and minimized noise levels. It offers greater energy efficiency and throughput, making it a cost-effective and environmentally responsible choice for various processing applications.Q: When should I consider using a Full Circle Hammer Mill in my production process?

A: You should consider integrating this hammer mill when you require consistent, high-capacity material reduction with minimal manual supervision, especially for agricultural, food processing, or recycling applications that demand reliability and efficiency.Q: Where can the Full Circle Hammer Mill be sourced in India?

A: The hammer mill is available through multiple channels in India, including distributors, manufacturers, exporters, retailers, suppliers, traders, and wholesalers. This widespread accessibility ensures support and quick delivery nationwide.Q: What is the process for installing and operating the Full Circle Hammer Mill?

A: Installation involves connecting the machine to a compatible electrical supply (230/440 Volt). Once set up, its automatic controls enable seamless operation with limited manual input. Comprehensive instructions from the supplier or manufacturer support safe setup and use.Q: Can the hammer mill be used for eco-friendly operations?

A: Absolutely. The hammer mill is designed with energy-efficient technology and operates at low noise levels, promoting sustainable practices while minimizing the environmental footprint of your processing operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Grinding, crushing and Pulverizing Machine Category

Pulses and Grains Grinding Pulverizer

Price 30000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 8 to 80 Kg/hr

Automatic : Yes

Voltage : 110 to 415 Volt (v)

Food Grinder

Price 56000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 30160 Kg/hr

Automatic : Yes

Voltage : 230/440 Volt (v)

Material : Stainless Steel

Pulverizing Machine

Price 18000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 202200 Kg/hr

Automatic : Yes

Voltage : 230/440 Volt (v)

Material : Stainless Steel

Sugar Grinding Machine

Minimum Order Quantity : 1 Unit

Capacity : 3035 Kg/hr

Automatic : Yes

Voltage : 110 to 415 Volt (v)

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free