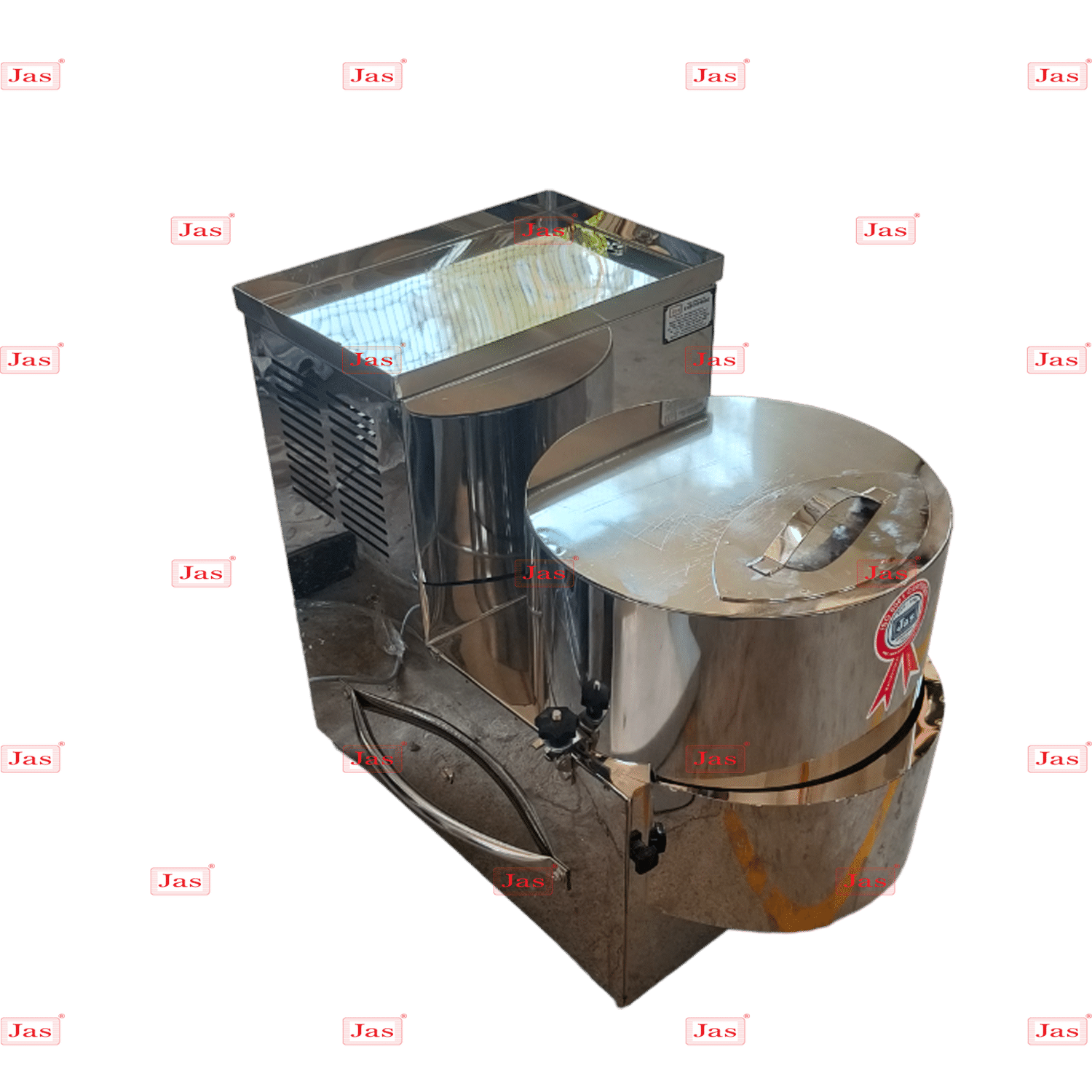

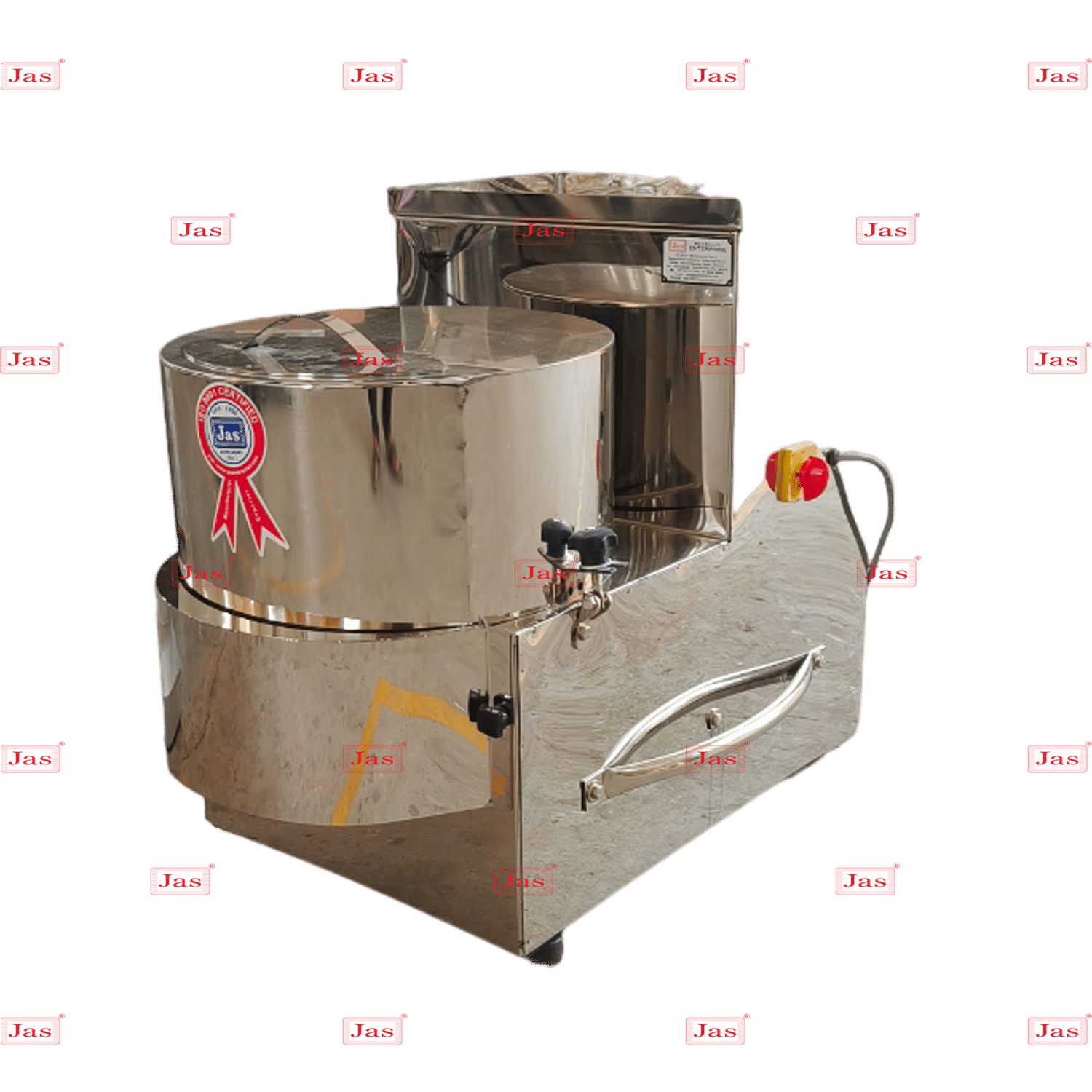

Price 24000 आईएनआर/ Unit

Specification

- क्षमता

- किलो/घंटा

- ऑटोमेटिक

- वोल्टेज

- वोल्ट (v)

- फ़ीचर

- , , , ,

Trade Information

- Minimum Order Quantity

- 1 Unit

- भुगतान की शर्तें

- , , , ,

- मुख्य निर्यात बाजार

- , , , , , , , ,

- मुख्य घरेलू बाज़ार

- , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , ,

- प्रमाणपत्र

- ISO

About

-

Cutting Mechanism Different models offer various cutting options such as blades for slicing dicing julienne and grating Some machines have interchangeable blades to provide versatility

Capacity Commercial vegetable cutters are designed to handle large volumes so consider the size of the hopper and the speed at which the machine processes vegetables

Material and Build Look for durable materials like stainless steel which is resistant to corrosion and easy to clean The build quality should be robust to withstand heavy use

Ease of Cleaning Machines with removable parts or those that can be easily disassembled will be easier to clean and maintain

Safety Features Ensure the cutter has safety mechanisms to protect users such as guards safety switches and nonslip feet

Size and Footprint Depending on your kitchen space you may need a compact model or one with a larger footprint

Power and Speed Higherpowered machines can cut through tougher vegetables more efficiently Check the motor power and speed settings

Attachments and Accessories Some models come with additional attachments or accessories like trays for collecting the cut vegetables or pusher tools to help with loading

Advanced Efficiency for High-Volume Kitchens

Engineered to process between 100 and 1000 kilograms of vegetables each hour, this commercial cutter is ideal for restaurants, hotels, and food processing plants. Its high efficiency allows users to meet demanding requirements without delays, all while maintaining energy efficiency and reducing operational costs. The intelligent design ensures consistent cutting results for a variety of vegetables.

Eco-Friendly and Low-Noise Operation

The vegetable cutter is thoughtfully constructed to minimize noise and energy usage, contributing to a quieter and more sustainable kitchen environment. Its eco-friendly features reduce the overall carbon footprint and ensure compliance with modern energy standards. This makes it an excellent choice for environmentally conscious food businesses.

Flexible Availability Across India

Available through leading distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers, this machine can be sourced conveniently from various channels across India. Its robust build and reliable service support make it a trusted investment for businesses of any scale.

FAQs of Commercial Vegetable Cutter:

Q: How does the commercial vegetable cutter streamline the vegetable preparation process?

A: The cutter automates the slicing, chopping, and dicing of vegetables, significantly reducing manual labor and preparation time. Its high-capacity mechanism enables users to process large volumesfrom 100 kg to 1000 kg per hourmaking it ideal for commercial operations.Q: What are the key features and benefits of this model?

A: This vegetable cutter boasts a compact structure, high efficiency, low noise, and eco-friendly engineering. It operates on 230/440 volts and consumes less energy, offering long-term savings. Users benefit from consistent vegetable cuts, faster turnaround, and a quieter work environment.Q: When is it recommended to use an automatic commercial vegetable cutter?

A: This equipment is best used when handling large quantities of vegetables is a routine requirementsuch as in catering services, hotels, restaurants, and food processing plants. It is especially useful during peak service hours or whenever rapid, uniform cutting is essential.Q: Where can I purchase or source this commercial vegetable cutter in India?

A: The product is widely available through distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers across India. This ensures businesses can conveniently find the best purchasing option to suit their needs.Q: What is the typical usage process for the vegetable cutter?

A: To use the machine, simply connect it to a 230/440-volt power supply, load the vegetables into the hopper, and select your desired cutting style. The automatic system processes vegetables without manual intervention, ensuring safety and efficiency.Q: How does the cutter support eco-friendly kitchen operations?

A: Its lower energy consumption and efficient design reduce electrical usage and associated emissions. This, combined with its quiet operation, makes it a sustainable choice for commercial kitchens aiming to lower their environmental impact.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in खाद्य प्रसंस्करण तंत्र Category

वाणिज्यिक पॉपकॉर्न बनाने की मशीन

मूल्य या मूल्य सीमा : आईएनआर

वोल्टेज : 110440 वोल्ट (v)

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 1

ऑटोमेटिक : हाँ

मुरुक्कू मेकिंग मशीन

मूल्य या मूल्य सीमा : आईएनआर

वोल्टेज : 110440 वोल्ट (v)

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 1

ऑटोमेटिक : हाँ

स्क्रू टाइप जूस एक्सट्रैक्टर

मूल्य या मूल्य सीमा : आईएनआर

वोल्टेज : 110 से 440 वोल्ट (v)

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 1

ऑटोमेटिक : हाँ

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें