Price 56000 आईएनआर/ Unit

Specification

- सामान्य उपयोग

- Industrial

- मटेरियल

- क्षमता

- किलो/घंटा

- कम्प्यूटरीकृत

- ऑटोमेटिक

- वोल्टेज

- वोल्ट (v)

- फ़ीचर

- , , , ,

- रंग

- वारंटी

- 1 Year

Trade Information

- Minimum Order Quantity

- 1 Unit

- भुगतान की शर्तें

- , , , ,

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- हफ़्ता

- मुख्य निर्यात बाजार

- , , , , , , , ,

- मुख्य घरेलू बाज़ार

- , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , ,

- प्रमाणपत्र

- ISO

About

-

Motor Power: Look for machines with powerful motors (usually measured in horsepower or watts) to handle tough ingredients and continuous use.

-

Grinding Plates and Blades: High-quality stainless steel plates and blades ensure durability and sharpness for efficient grinding.

-

Feed Hopper Size: A larger feed hopper allows for more food to be processed at once, which is useful for high-volume tasks.

-

Multiple Grinding Settings: Different settings or plates for coarse and fine grinding provide versatility in food preparation.

-

Build Quality: Heavy-duty machines are typically made from sturdy materials like stainless steel or cast iron to withstand rigorous use.

-

Ease of Cleaning: Removable parts and dishwasher-safe components make cleaning easier and more efficient.

-

Safety Features: Look for features like overload protection, non-slip feet, and safety switches to ensure safe operation.

-

Size and Portability: Depending on your space and needs, consider whether you need a stationary machine or one that is easier to move around.

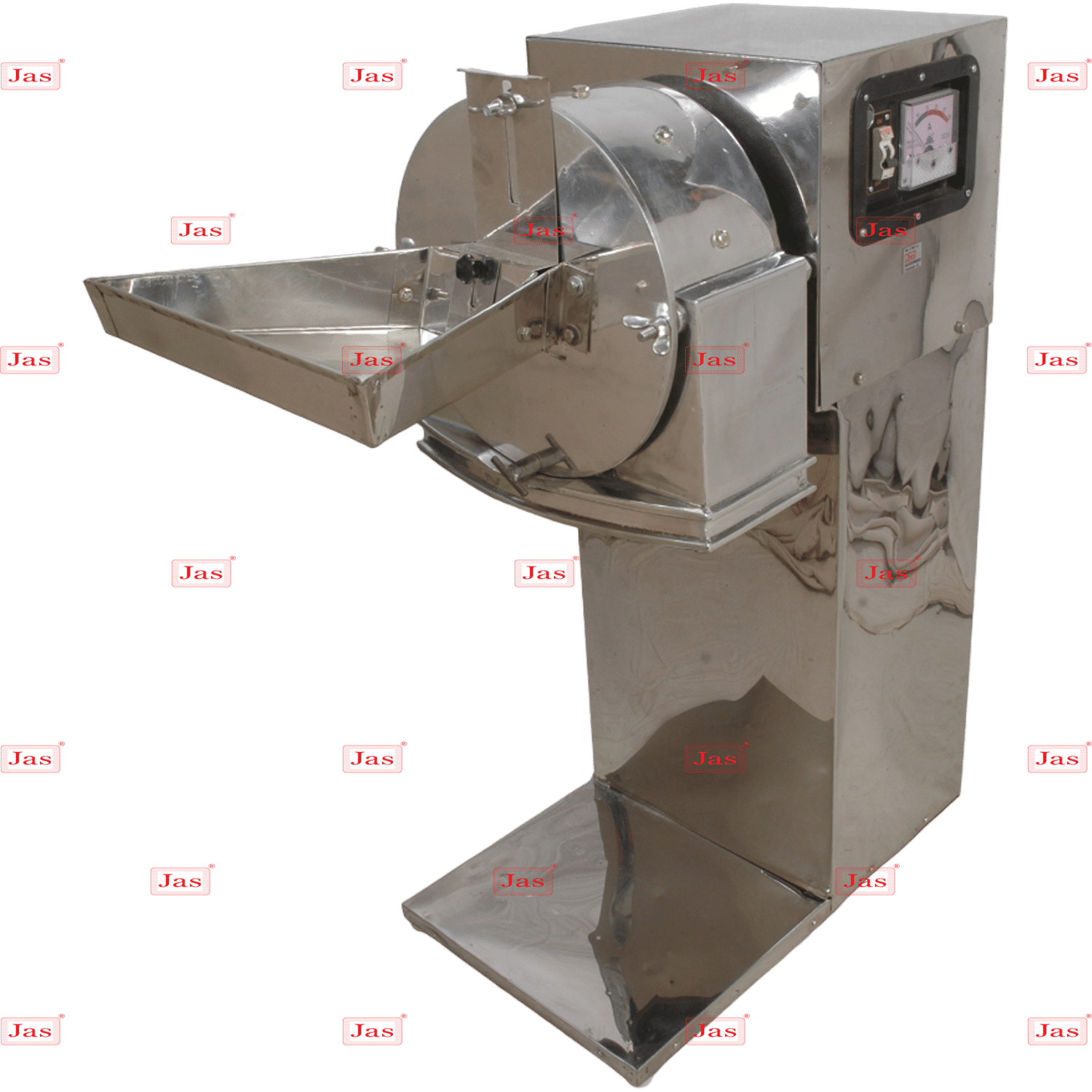

Advanced Industrial Grinding Solutions

This heavy duty grinding machine combines cutting-edge technology with high efficiency to handle demanding grinding tasks in industrial environments. Featuring an automatic operation and a robust stainless steel construction, the machine ensures reliable, consistent grinding while lowering energy consumption and environmental impact. Its versatile capacity accommodates multiple industrial needs.

Remarkable Energy Savings & Performance

Operating at both 230 and 440 Volt, this grinding machine is designed for optimal power management, minimizing electricity use without compromising performance. Low noise levels and eco-friendly features make it a preferred choice for industries seeking sustainable manufacturing processes, alongside the assurance provided by a 1-year warranty.

FAQs of Heavy Duty Grinding Machine:

Q: How does the heavy duty grinding machine ensure high performance while maintaining low energy consumption?

A: The machine uses advanced engineering and automatic systems to optimize grinding efficiency. Its powerful motor and precision components reduce energy requirements while delivering consistent high output.Q: What materials can be processed with this industrial grinding machine?

A: Designed primarily for industrial applications, this machine can efficiently process various materials such as grains, spices, and other commercial goods suitable for grinding, thanks to its robust stainless steel build.Q: When is regular maintenance required for the grinding machine?

A: For optimal performance, standard maintenance is recommended every 3-6 months, depending on usage intensity. The stainless steel construction simplifies cleaning and upkeep.Q: Where can I purchase or source this heavy duty grinding machine in India?

A: It is available through authorized distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers across India. Contacting these channels ensures access to genuine products and support.Q: What is the process for operating the machine automatically?

A: To operate, connect to the appropriate voltage supply (230/440V), load raw materials, and use the machines simple automatic controls. The system manages grinding operations efficiently with minimal manual intervention.Q: How does using this grinding machine benefit industrial operations?

A: Benefits include increased grinding speed and efficiency, lower operating costs due to reduced energy consumption, compliance with eco-friendly standards, low noise, and a sturdy stainless steel design for longevity.Q: Is the machine computerized, and what warranty support is provided?

A: No, the machine is not computerized, but its automatic functions streamline operations. It comes with a 1-year warranty, covering manufacturing defects and ensuring reliable service support.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in पीस, कुचलने और मशीन को पल्स करना Category

जैकेटेड मिनी पुल्वराइज़र

न्यूनतम आदेश मात्रा : 01

मूल्य की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : यूनिट/यूनिट

वोल्टेज : 110 से 415 वोल्ट (v)

आटा चक्की मशीनरी और सहायक उपकरण

न्यूनतम आदेश मात्रा : 1

मूल्य की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : यूनिट/यूनिट

वोल्टेज : 110 वोल्ट (v)

क्षमता : 3035 किलो/घंटा

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें