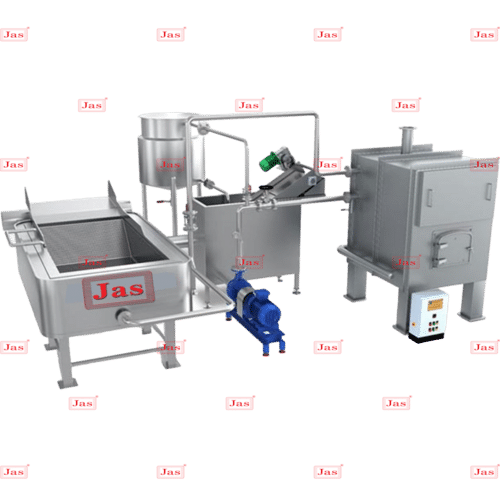

Industrial Batch Fryer

Price 17799.0 INR/ Unit

Industrial Batch Fryer Specification

- Capacity

- 12-32 Ltr/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Industrial Batch Fryer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Industrial Batch Fryer

-

Capacity: Industrial batch fryers come in various sizes, from smaller units that handle a few hundred pounds of food per batch to large models that can process thousands of pounds.

-

Heating System: They typically use gas or electric heating elements to reach and maintain the high temperatures required for frying. Some models may use oil heaters or direct flame.

-

Temperature Control: Precise temperature control is crucial for achieving consistent results and ensuring food safety. Most batch fryers come with adjustable thermostats and digital controls.

-

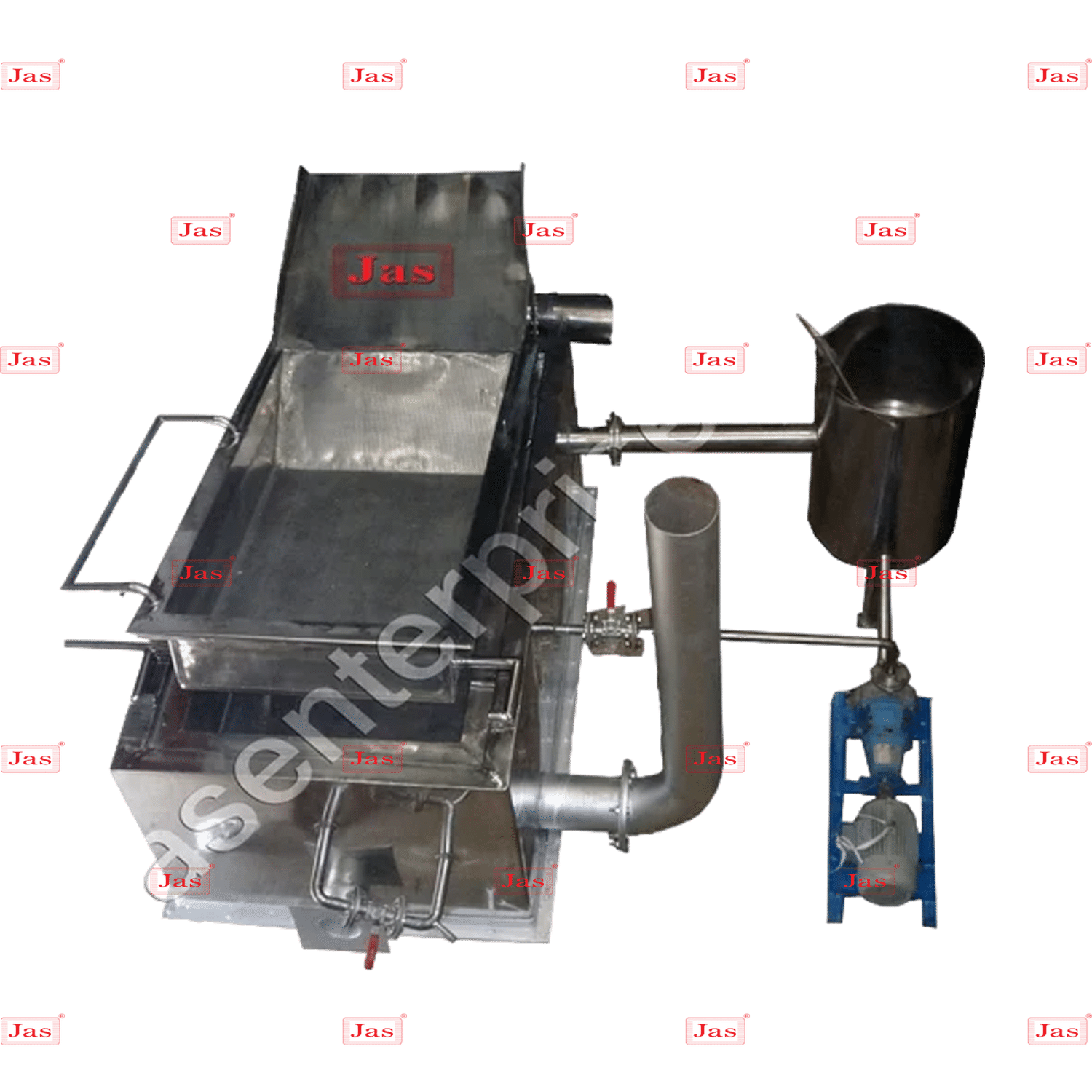

Oil Filtration: Many industrial fryers are equipped with oil filtration systems to extend the life of the oil and maintain the quality of the fried products.

-

Basket and Racking Systems: Batch fryers often use baskets or racks to hold the food while it fries. These systems can be manually or automatically operated, depending on the model.

-

Cooling and Draining: After frying, the food needs to be cooled and drained. Some fryers have built-in systems for this, while others may require separate equipment.

-

Safety Features: These can include automatic shut-off systems, over-temperature alarms, and safety guards to prevent accidents.

-

Ease of Cleaning: Since frying involves oil, which can be messy, many industrial fryers are designed for easy cleaning with features like removable parts and smooth surfaces.

Eco-Friendly and Efficient Performance

The Industrial Batch Fryer is designed with energy conservation and environmental impact in mind. Its advanced features, such as lower energy consumption and quiet operation, make it ideal for urban and rural locations alike. This solution ensures high frying efficiency while supporting responsible production practices.

Versatile Usage for Multiple Businesses

Whether you are a manufacturer, supplier, trader, or wholesaler, the batch fryer integrates seamlessly into food processing lines. Its compact structure facilitates easy installation and adaptability to different scales of operation. From small restaurants to large food factories, it elevates productivity while maintaining quality.

FAQs of Industrial Batch Fryer:

Q: How does the automatic function of the Industrial Batch Fryer enhance cooking efficiency?

A: The automatic operation streamlines frying processes by regulating temperature, timing, and oil management, resulting in consistent batch quality and minimizing the need for manual intervention.Q: What benefits can businesses expect from the fryers low energy consumption and eco-friendly features?

A: Businesses can reduce operational costs while adhering to environmental standards. Lower energy consumption decreases electricity expenses, and the eco-friendly design supports sustainable production, making it ideal for responsible enterprises.Q: When is the optimal time to use the Industrial Batch Fryer in your production cycle?

A: The fryer should be used during peak production hours when batch frying is required, as its high efficiency and quick cycle times enable rapid turnover without compromising quality.Q: Where is the Industrial Batch Fryer most commonly installed in food processing setups in India?

A: This fryer is frequently installed in commercial kitchens, food factories, and industrial facilities throughout India, especially where space-saving, efficient, and reliable batch frying is necessary.Q: What is the process for maintaining the fryer to ensure continued high efficiency and low noise operation?

A: Routine maintenance involves regular cleaning, scheduled component inspections, and following manufacturer guidelines for lubrication and calibration to preserve optimal performance and quieter operation.Q: How can users maximize the capacity range of 12-32 ltr/hr for different batch sizes?

A: Users can adjust batch inputs according to demand, utilizing the fryers adjustable settings to scale up or down within its specified capacity, ensuring flexibility in production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Puff Extruder Machine

Price 250000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Automatic : Yes

Installation Type : Free Stand

Computerized : No

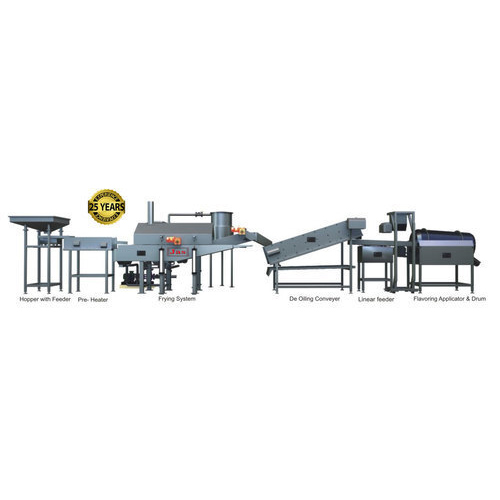

Automatic Snacks Frying Machine

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Automatic : Yes

Installation Type : Free Stand

Computerized : No

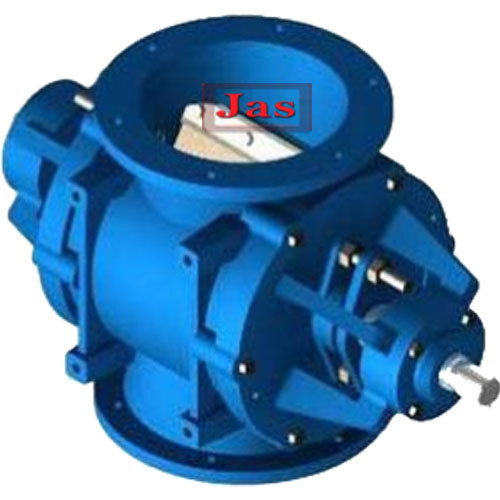

Rotary Airlock Feeder And Valve

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Automatic : Yes

Installation Type : Free Stand

Computerized : No

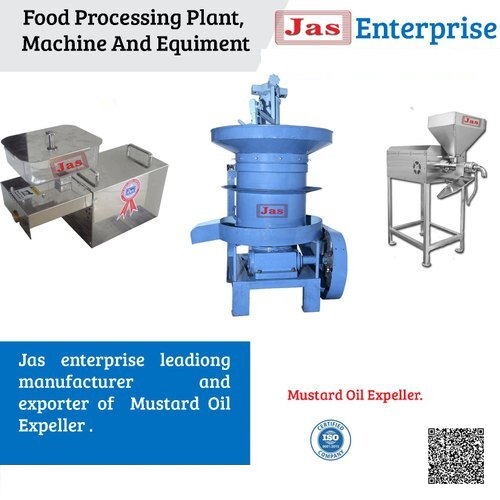

Mustard Oil Expeller

Price 20000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Automatic : Yes

Installation Type : Free Stand

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS