Industrial Fryums Extruder Machine

Price 25500 INR/ Unit

Industrial Fryums Extruder Machine Specification

- Automation Grade

- Automatic

- Power Source

- Electric

- General Use

- Industrial

- Material

- Stainless Steel

- Capacity

- 14-60 Kg/hr

- Computerized

- No

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Color

- Other

- Warranty

- 1 Year

Industrial Fryums Extruder Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Industrial Fryums Extruder Machine

Key Components and Functions:

-

Feeding System: The machine has a hopper where ingredients (like flour, starch, and seasoning) are fed into the extruder.

-

Extruder Barrel and Screw: Inside the machine, the barrel contains a rotating screw that mixes and kneads the ingredients. The screws rotation applies pressure and heat to the mixture, causing it to cook and expand.

-

Die Head: The extruded mixture is forced through a die head, which shapes the dough into various forms (e.g., rings, stars, or other shapes).

-

Cutting System: After exiting the die head, the extrudate is cut into desired lengths by a cutting mechanism.

-

Cooling System: The fried or baked fryums are cooled to harden and become crisp.

-

Frying System: Some machines include an integrated frying unit. Alternatively, the fryums can be fried in a separate fryer after extrusion.

Efficient Automatic Operation

This extruder machine operates automatically, reducing manual intervention and enhancing productivity. Designed for industrial settings, it facilitates consistent and high-quality output with minimal operational hassle. Its computerized-free architecture streamlines the process and offers ease of control, making it a preferred choice for manufacturers and distributors.

Eco-Friendly and Cost-Effective Design

Built with eco-friendly features, the machine provides lower noise levels and reduced energy consumption, contributing to a healthier work environment and lower operational costs. The stainless steel construction ensures durability and robust performance, supporting heavy-duty production cycles required in industrial contexts.

FAQs of Industrial Fryums Extruder Machine:

Q: How does the Industrial Fryums Extruder Machine work?

A: The machine automatically processes raw materials into fryums using electric power (230/440V). It extrudes and shapes fryums with consistent quality, all without the need for computerized controls, making operation straightforward and reliable for industrial users.Q: What is the production capacity of this machine?

A: Depending on configuration and usage, the machine can produce between 14 to 60 kg of fryums per hour. This makes it suitable for large-scale manufacturing setups seeking efficient, continuous production.Q: When is the best time to conduct maintenance on the extruder?

A: Regular maintenance should be scheduled after every significant production cycle or as recommended by the manufacturer. Preventive checks help ensure optimal performance, prolong machine lifespan, and minimize unexpected downtime.Q: Where is this fryums extruder machine distributed and sold in India?

A: This machine is available nationwide through various channels, including exporters, distributors, manufacturers, suppliers, retailers, traders, and wholesalers based in India, ensuring widespread availability for industrial purchasers.Q: What is the benefit of the automatic and eco-friendly features?

A: The automatic operation cuts down manual labor and errors, leading to higher efficiency and output consistency. Eco-friendly aspects, including low energy consumption and noise, help reduce operational costs and promote a sustainable manufacturing environment.Q: How do users operate the machine without computerization?

A: Operators manage the machine through mechanical controls and pre-set functions that do not require a computer interface, simplifying the process while maintaining precise operation for industrial fryums production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Paddle Mixer Machine

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 440 Volt (v)

Installation Type : Free Stand

Computerized : Yes

Peeling Machine

Price 18000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 440 Volt (v)

Installation Type : Free Stand

Computerized : No

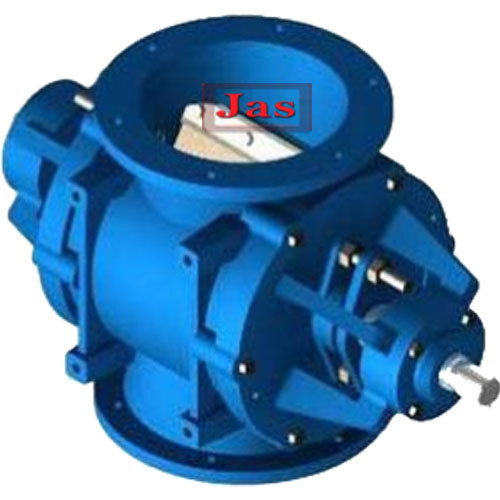

Rotary Airlock Feeder And Valve

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 440 Volt (v)

Installation Type : Free Stand

Computerized : No

Vibro Cleaner

Price 45000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 440 Volt (v)

Installation Type : Free Stand

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS