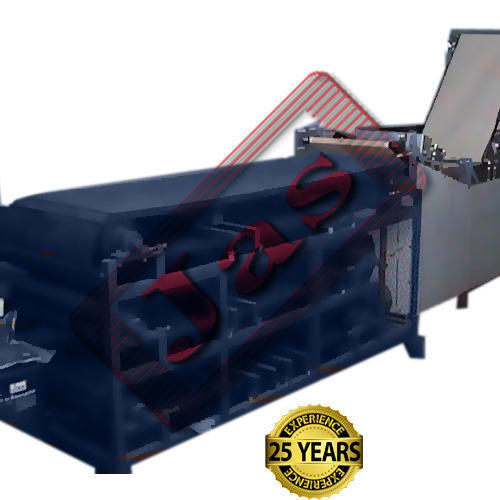

Jowar Roti Making Machine

Jowar Roti Making Machine Specification

- Product Type

- Semi Automatic

- General Use

- Jowar roti, jowar bhakri, jolada rotti Making

- Material

- Food Grade

- Capacity

- 500 Kg/hr

- Weight (kg)

- 180 Kilograms (kg)

- Product Thickness

- 1 Millimeter (mm)

- Product Shape

- Round

- Computerized

- No

- Automatic

- No

- PLC Control

- No

- Voltage

- 110/220/380/415 Volt (v)

Jowar Roti Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- All India

- Certifications

- ISO 9001: 2008 Certified

About Jowar Roti Making Machine

FAQs of Jowar Roti Making Machine:

Q: What types of products can be made using this Jowar Roti Making Machine?

Q: Is this machine fully automatic?

Q: What is the production capacity of the machine?

Q: What shape and thickness does the machine produce?

Q: Where is this machine manufactured?

Efficient and Reliable Roti Production

This jowar roti making machine delivers high output up to 500 kg per hour, ideal for environments with high demand. It produces round rotis consistently at a precise thickness of 1 mm, ensuring uniformity for every batch. Its manual controls offer reliability and simplicity without the need for computerized settings.

Versatile Voltage Compatibility

The machine accommodates multiple voltage standards110, 220, 380, and 415 Voltsallowing installation in varied industrial and commercial settings across India. Its sturdy, food-grade construction ensures durability and safety in continuous operations.

Perfect for Multiple Applications

Specifically engineered for jowar roti, bhakri, and jolada rotti, this machine caters to different regional preferences and menus. It is ideally distributed, exported, supplied, and retailed by leading providers in India, guaranteeing accessibility for diverse user requirements.

FAQs of Jowar Roti Making Machine:

Q: How does the Jowar Roti Making Machine operate without automatic or computerized controls?

A: The machine is designed for manual operation without automation or computerized controls, offering simple, hands-on use. Operators manually control the process, resulting in precise, customizable results and low maintenance requirements.Q: What types of jowar-based products can be made with this machine?

A: This machine is suitable for making round jowar roti, jowar bhakri, and jolada rotti, accommodating a range of regional Indian flatbreads with consistent thickness and shape.Q: When is the Jowar Roti Making Machine ideal to use in a business setup?

A: This machine is best suited for busy commercial kitchens, catering companies, restaurants, or wholesale operations needing large quantities of uniform rotis, especially when high-volume, consistent output is required.Q: Where can the Jowar Roti Making Machine be installed?

A: Thanks to its voltage compatibility and robust build, the machine can be installed in a variety of settings, including restaurants, factories, and food processing units across India, wherever local voltage provisions (110/220/380/415 V) are available.Q: What is the process for creating rotis using this equipment?

A: The process involves preparing jowar dough and feeding it into the machine. The operator then manually shapes and presses the dough into round rotis, which the machine flattens to a 1 mm thickness, ready for further cooking.Q: What are the key benefits of using this non-automatic jowar roti making machine?

A: Major benefits include high production capacity, simple manual operation, flexibility for varying recipes, and the assurance of food-grade safety. It is cost-effective, requires minimal technical training, and provides reliable performance for large-scale food preparation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chapati Making Machines Category

Fully Automatic Chapati Making Machine

Price 10000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 600 to 3000 Chapati/Hr Pcs/min

Automatic : Yes

Feature : High Quality, Non Stick Coating, Environment Friendly, Low Noise, High Efficiency, Multi Functional

Voltage : 110 440 Volt (v)

Raw Chapati Making Machines

Price 10000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 600 to 3000 Chapati/Hr Pcs/min

Automatic : Yes

Feature : High Quality, Non Stick Coating, Environment Friendly, Low Noise, High Efficiency, Multi Functional

Voltage : 110 440 Volt (v)

roti making machine

Capacity : 10001200 rotis/hour

Automatic : Yes

Feature : Efficient operation high production rate, Other

Voltage : 220240 V

Phulka Roti Making Machine

Price 10000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 600 to 3000 Roti/Hr Pcs/min

Automatic : Yes

Feature : High Quality, Non Stick Coating, Environment Friendly, Low Noise, High Efficiency, Multi Functional

Voltage : 110 440 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free