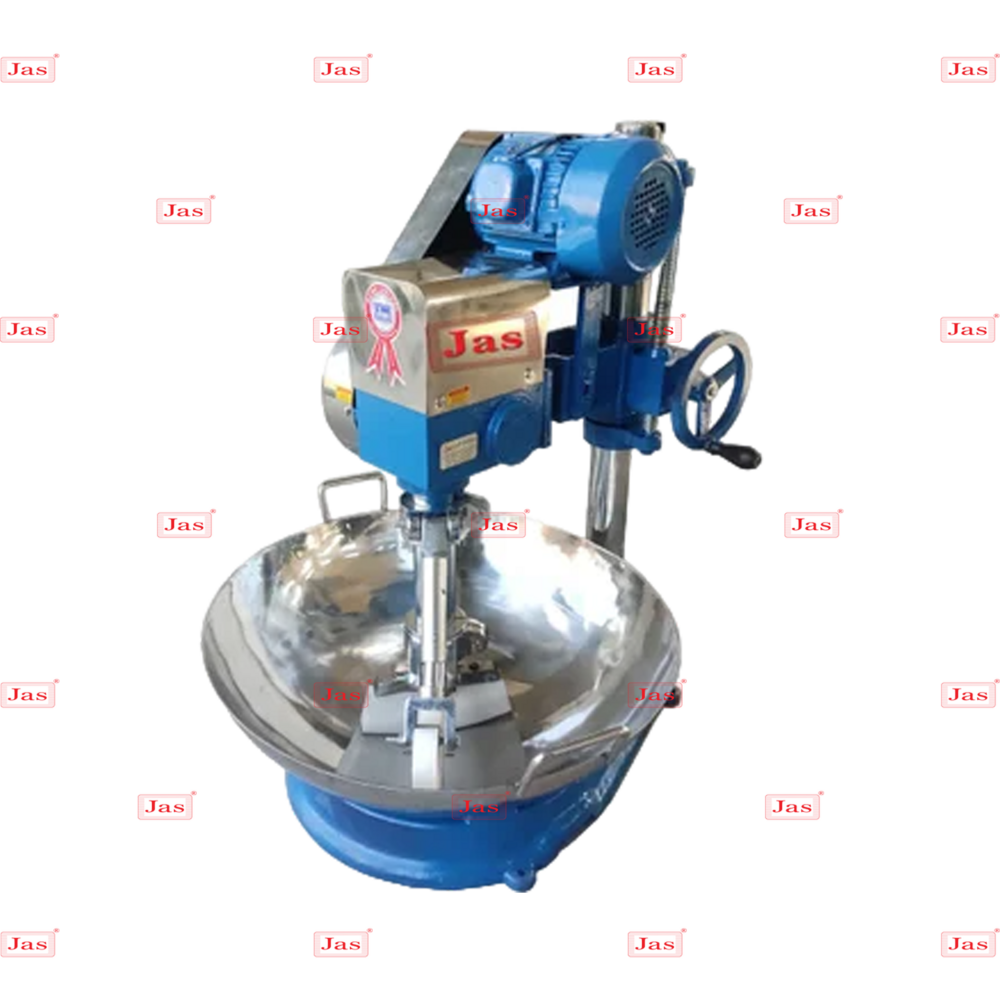

Mawa And Basundi Making Machine

Mawa And Basundi Making Machine Specification

- Material

- Stainless Steel

- Capacity

- 5 to 200 per Batch Kg/day

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Installation Type

- Free Stand

- Warranty

- One year against manufacturing defects at our site, except all wear and tear parts.

Mawa And Basundi Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 1000 Units Per Month

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Asia, Central America, Eastern Europe, North America, Africa

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Tripura, Manipur, Pondicherry, Uttarakhand, Dadra and Nagar Haveli, South India, North India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Daman and Diu, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Maharashtra, Mizoram, Meghalaya, Nagaland, Odisha, Rajasthan, Sikkim, Tamil Nadu, Telangana, West Bengal, Delhi, Gujarat, Madhya Pradesh, Punjab, East India, Andhra Pradesh, Central India, West India, Chhattisgarh, Uttar Pradesh, All India

- Certifications

- ISO 9001

About Mawa And Basundi Making Machine

We are engaged in offering our clients with Basundi Machine that are available in various sizes, shapes and models at market leading prices. All our machines are widely acclaimed by the customers for their corrosion & abrasion resistance, robust constraint and excellent performance. Our machines are designed in compliance with international quality norms, using premium raw material, obtained from the reliable vendors of the market.

Advanced PLC Control System

Equipped with a modern PLC control system, this machine allows accurate and seamless operation, reducing manual intervention. The advanced automation not only ensures consistency in quality but also enhances overall productivity, making it suitable for high-volume production environments.

Versatile Capacity & Usage

Adaptable to varying production requirements, the machine handles batch sizes from 5 to 200 kg per day. Its automated process streamlines the making of traditional delicacies like mawa and basundi, catering to small and large-scale businesses alike. The stainless steel construction guarantees food safety and lasting performance.

FAQs of Mawa And Basundi Making Machine:

Q: How is the Mawa and Basundi Making Machine installed and operated?

A: This machine features a free-stand installation, making setup simple and versatile. After installation, operation is straightforward due to the computerized PLC control system, allowing users to automate most processes with minimal training.Q: What materials are used in the construction of this machine?

A: The machine is manufactured from premium stainless steel, ensuring high durability, easy cleaning, and compliance with strict hygiene standards vital for dairy processing.Q: When should wear and tear parts be checked or replaced?

A: Routine maintenance is recommended to inspect wear and tear parts regularly, as these components are not covered under the one-year warranty. The replacement frequency varies depending on usage intensity.Q: Where can this machine be used?

A: This versatile equipment is suitable for dairy plants, sweet shops, food processing industries, and large-scale kitchens across India, thanks to its flexible capacity and easy installation.Q: What is the process of making mawa and basundi in this machine?

A: The automated system controls heating, stirring, and reduction processes for milk, ensuring consistent texture and flavor. Users simply load the ingredients and set batch parameters through the PLC interface.Q: How does the machine benefit dairy and food processing businesses?

A: Automation increases efficiency and batch consistency, while stainless steel construction ensures hygienic production and easier maintenance. The broad capacity range caters to both small and large operations, optimizing resource usage and output.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sweets Making Machine Category

Mysore Pak making machine

Price Range 100000.00 - 325000.00 / Unit

Minimum Order Quantity : 1 Unit

Capacity : 20 50 Kg/hr

Voltage : 230 Volts Volt (v)

Warranty : One year against manufacturing defects at our site, except all wear and tear parts.

Steam Kadai Type Khoa Machine

Price 67500 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 32150 Ltr/hr

Voltage : 230 Volt (v)

Warranty : One year against manufacturing defect at our side

Stainless Steel Khoya Making Machine Gas operated

Price Range 90000.00 - 230000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 5 to 200 liters per Batch Liter/day

Warranty : One year against manufacturing defects at our site, except all wear and tear parts.

Kaju Muska Machine

Price 68000 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : 1015 kg/betch Pcs/hr

Voltage : 230 Volt (v)

Warranty : One year against manufacturing defect at our side

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS