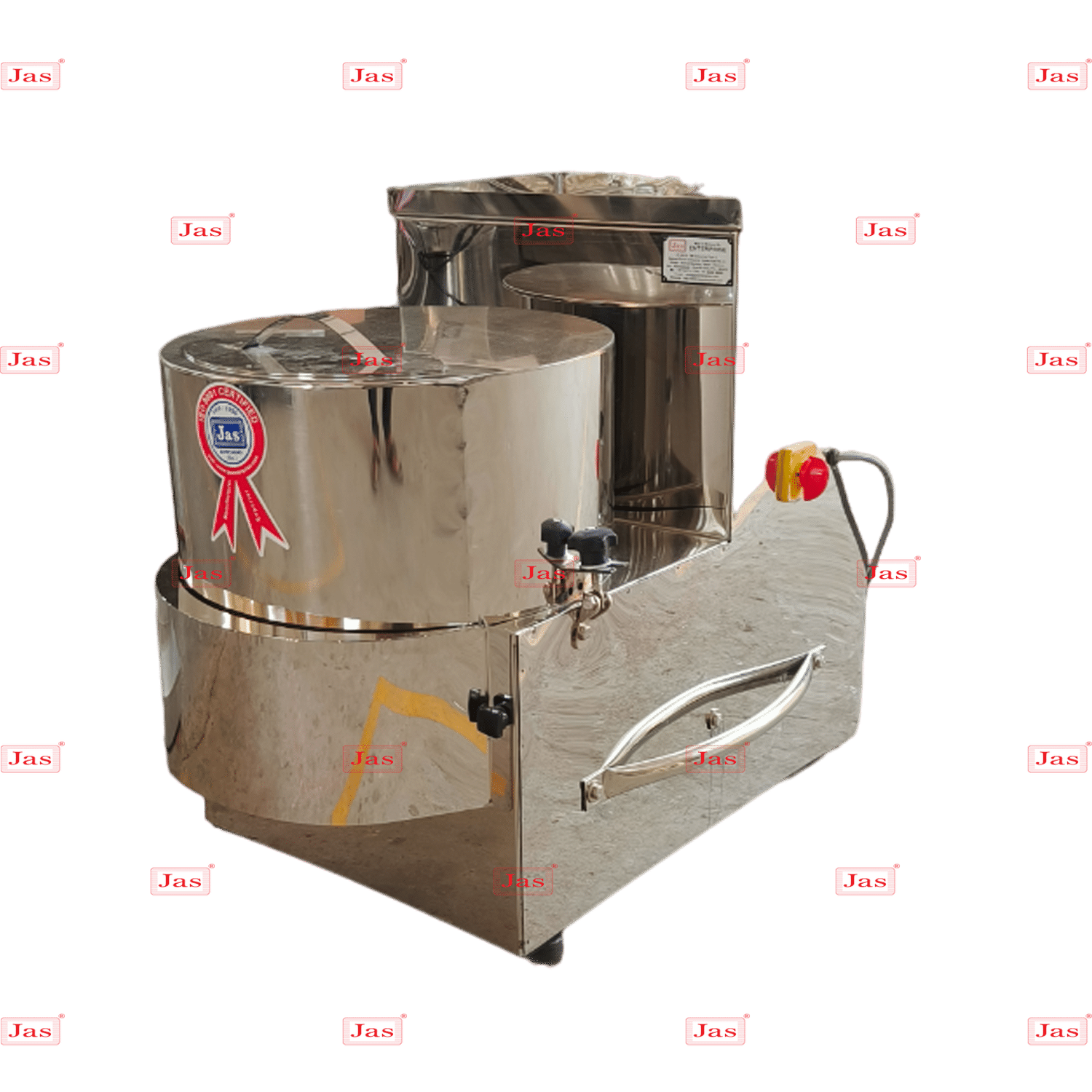

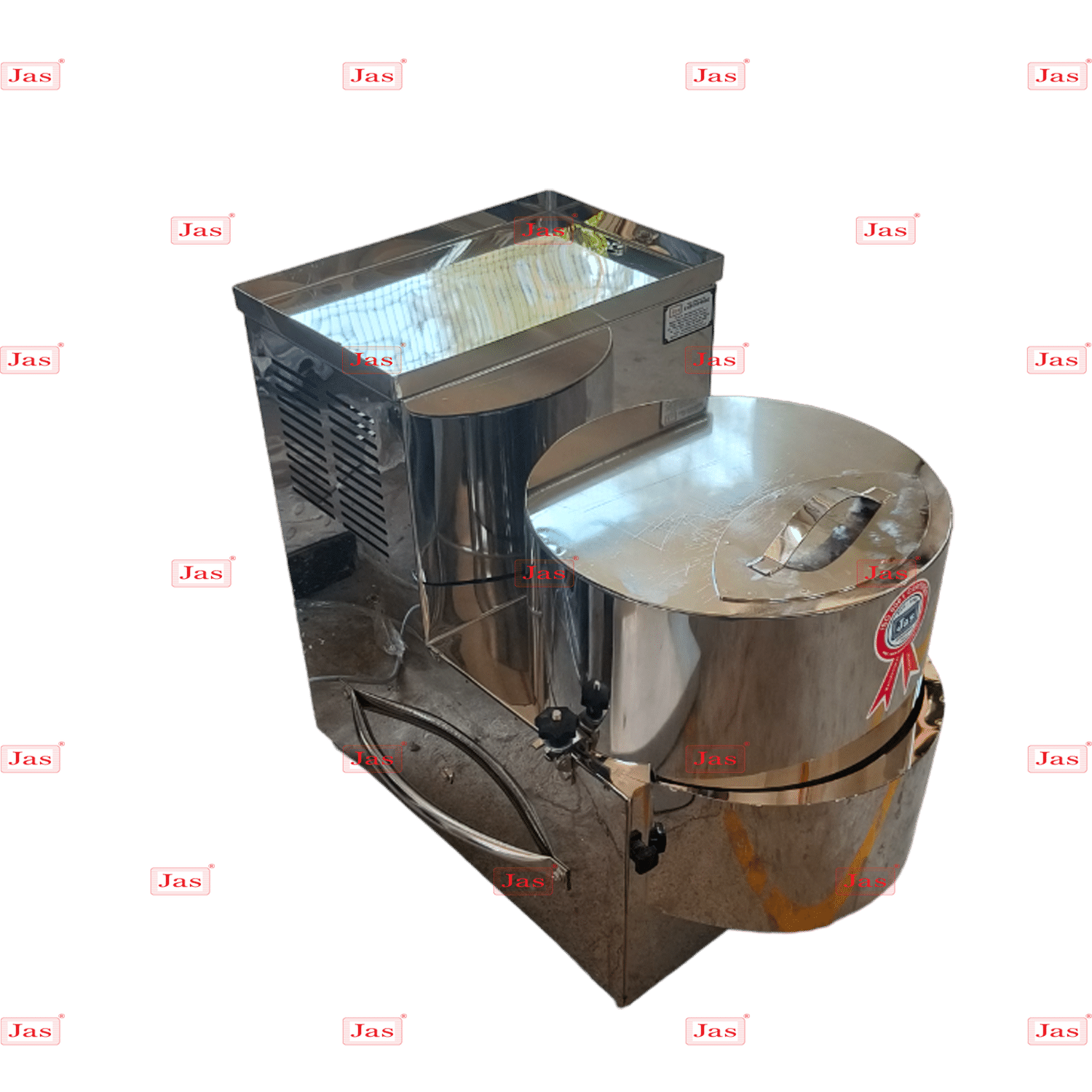

Metallic Vegetable Cutter

Price 25000 INR/ Unit

Metallic Vegetable Cutter Specification

- Capacity

- 100-1000 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Metallic Vegetable Cutter Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Metallic Vegetable Cutter

-

Manual Handheld Vegetable Slicers: These are usually compact and have interchangeable metal blades for slicing, julienning, or shredding vegetables. They are operated by hand, requiring the user to push the vegetable through the blades.

-

Electric Food Processors: These machines often have metal blades that rotate or oscillate to chop, slice, or shred vegetables. They are more powerful and can handle larger quantities of vegetables compared to manual slicers.

-

Mandoline Slicers: These are handheld or countertop devices with a flat, metal slicing surface and an adjustable blade for slicing vegetables into consistent thicknesses. They are popular for creating uniform slices quickly.

-

Multi-function Kitchen Appliances: Some food processors or kitchen mixers come with vegetable cutting attachments that include metal blades for different cutting styles, such as slicing, grating, or dicing.

Eco-Friendly and Energy-Efficient Operation

The Metallic Vegetable Cutter is crafted with an emphasis on sustainability, significantly lowering energy consumption while maintaining high performance. Its eco-friendly attributes contribute both to operational savings and reduced environmental impact. With low noise levels, it provides a quieter work environment, especially important in busy commercial kitchens.

Automated Cutting for High Efficiency

This vegetable cutter features an automatic mechanism that simplifies the slicing and chopping process. The high efficiency allows for continuous operation, processing from 100 up to 1000 kg of vegetables every hour. Automation reduces manual labor, making it ideal for bulk vegetable processing needs.

Robust Structure and Flexible Installation

Thanks to its compact build, the cutter fits easily into various food preparation setups without requiring excess space. The robust metallic body ensures durability, supporting long-term use in demanding environments. Operating on 230/440 volt (v) power supply, it adapts seamlessly in commercial kitchens and industrial food lines.

FAQs of Metallic Vegetable Cutter:

Q: How does the automatic metallic vegetable cutter process such large volumes efficiently?

A: The cutter utilizes a high-powered motor and automated slicing technology, allowing it to process between 100 and 1000 kg of vegetables per hour. Its compact structure helps optimize space, while components are engineered to ensure consistent and uniform cutting results.Q: What are the main benefits of using this eco-friendly vegetable cutter in commercial kitchens?

A: Key advantages include lower energy consumption, reduced noise levels, and high operational efficiency. These features collectively minimize costs, provide a safer and quieter workspace, and contribute to a more sustainable kitchen environment.Q: When is it ideal to use this vegetable cutter in industrial or retail settings?

A: This cutter is best suited for times of peak demand, such as during large batch meal preparations, food processing, or when handling bulk quantities in restaurants, hotels, and food distribution centers.Q: Where can I purchase or source the metallic vegetable cutter in India?

A: The cutter is available through various channels in India, including distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers. Interested buyers can contact these entities for procurement or further information.Q: What is the process for operating the automatic vegetable cutter?

A: Simply connect the cutter to a compatible power source (230/440 volt), load the vegetables, and choose the desired cutting settings. The machine automatically performs slicing, significantly reducing the need for manual labor and monitoring.Q: How does the compact design benefit the usage of this vegetable cutter?

A: The compact structure enables easy installation even in space-constrained environments, while maintaining robust performance. It is particularly advantageous for kitchens with limited room but high processing requirements.Q: What safety features ensure the reliable use of this cutter in busy environments?

A: The cutter is built with safety mechanisms such as stable metallic housing and automated shut-off functions to minimize risks during operation. Its low noise and efficient energy use further enhance workplace safety and comfort.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Khoya Making Machine

Price 25000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220240 V

Feature : Other, Energy Efficient, Low Maintenance

Automation Grade : SemiAutomatic / Automatic

Material : Other, Stainless Steel (SS 304/316 Grade)

Cheese Grater

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Feature : Lower Energy Consumption, ECO Friendly, Low Noice, High Efficiency, Compact Structure

Material : Stainless Steel

Commercial Electric Pizza Oven

Price 7000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Automation Grade : Automatic

Material : Stainless Steel

Cabbage Cutter Machine

Price 16500.00 INR / Piece

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Automation Grade : Semi Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free