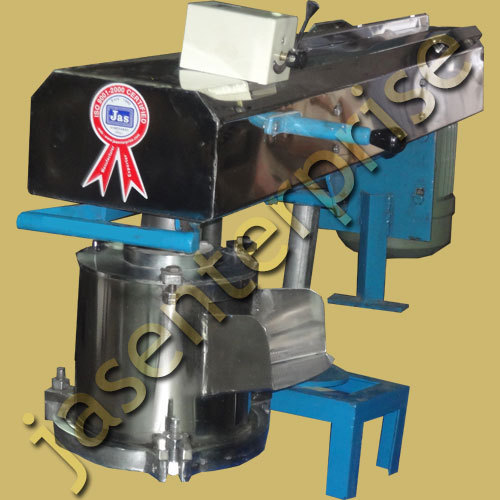

Namkeen Masala Mixing Tilting Type Machine

Price 21000 INR/ Unit

Namkeen Masala Mixing Tilting Type Machine Specification

- Phase

- Single Phase / Three Phase

- Frequency

- 50-60 Hertz (HZ)

- Automation Grade

- Semi Automatic

- Capacity

- 25-100 Kg/hr

- Voltage

- 230/440 Volt (v)

- Power

- 0.5-3 Horsepower (HP)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Warranty

- One year against manufacturing defect at our side

Namkeen Masala Mixing Tilting Type Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Namkeen Masala Mixing Tilting Type Machine

The Namkeen Masala Mixing Tilting Type Machine is an essential piece of equipment for snack processing industries specially engineered to ensure the efficient uniform and hygienic mixing of masalas spices and seasonings with a wide variety of fried or roasted snack products such as namkeen farsan boondi sev aloo bhujia chana dal potato chips fryums and more

Constructed using highgrade stainless steel SS202 or SS304 this machine guarantees robust performance superior hygiene standards corrosion resistance and long operational life The heart of the machine is its tilting cylindrical drum or coating pan which allows for easy discharge of mixed products without manual handling or spillagethereby increasing operational efficiency and minimizing waste

Advanced Mixing Technology for Namkeen Production

This semi-automatic tilting type masala mixing machine is crafted to ensure even distribution of spices in namkeen, making it a preferred choice for food processing businesses. Its robust engineering allows it to handle substantial batch sizes, catering to both small-scale and large-scale production needs. The tilting function enhances convenience, ensuring smooth discharge of the mixed product.

Reduced Energy Consumption and Noise Levels

Engineered for efficiency, the machine features lower energy consumption without compromising on performance. Its noise-minimizing design creates a more comfortable working environment. The compact structure also saves valuable floor space in your production area, making it suitable for businesses with limited facility sizes.

FAQ's of Namkeen Masala Mixing Tilting Type Machine:

Q: How does the tilting mechanism benefit the mixing process?

A: The tilting mechanism allows for easy and complete discharge of mixed namkeen and masala, reducing manual labor and minimizing product waste. This feature enhances overall efficiency in the production process and ensures quick batch turnovers.Q: What voltage and phase options are available for this machine?

A: The machine operates on either 230 or 440 volts and is compatible with both single-phase and three-phase power supplies, giving you flexibility according to your facility's electrical setup.Q: When should the machine be used in the namkeen preparation process?

A: The masala mixing machine should be employed after the namkeen base is fried or baked and ready for seasoning. It thoroughly combines spices with the finished product just before packaging or further processing.Q: Where can this machine be installed and used?

A: This versatile machine is ideal for use in snack food factories, commercial kitchens, and small to medium-scale namkeen manufacturing setups. Its compact design makes it adaptable to diverse installations, especially where space optimization is necessary.Q: What is the typical process for mixing namkeen using this machine?

A: Simply load the base namkeen and required masala into the drum, set operation controls, and allow the machine to evenly mix the contents. Once mixing is completed, use the tilting function to discharge the seasoned product efficiently.Q: What are the key usage benefits of this semi-automatic masala mixing machine?

A: Benefits include reduced manual effort, consistent spice blending, eco-friendly operation, energy savings, minimal product loss, and ease of maintenance with a warranty to ensure peace of mind.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Namkeen Making Machine Category

Boondi making machine

Price 22000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Other, High Production, Easy Operation, Consistent Size

Capacity : 100150 kg/hr

Automatic : Yes

Farsan Machine

Price Range 22000.00 - 65000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Lower Energy Consumption, ECO Friendly, High Efficiency, Low Noice, Compact Structure

Capacity : 25200 Kg/hr

Automatic : Yes

Hydro Extractors

Price Range 28000.00 - 120000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Lower Energy Consumption, High Efficiency, Low Noice, Compact Structure

Capacity : 7 to 60 Kg/hr

Automatic : Yes

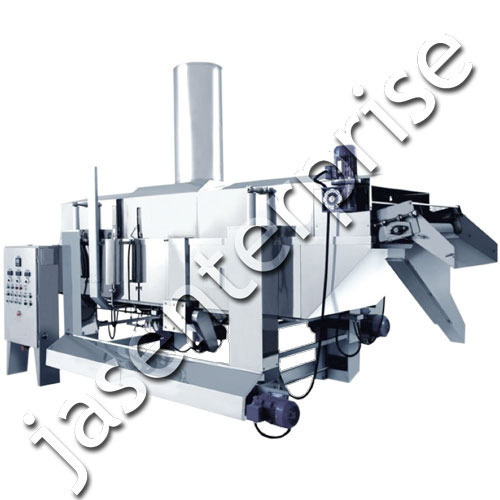

Continuous Frying Systems

Price Range 1800000.00 - 10000000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, High Efficiency, Compact Structure

Capacity : 300 to 350 Kg/hr

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS