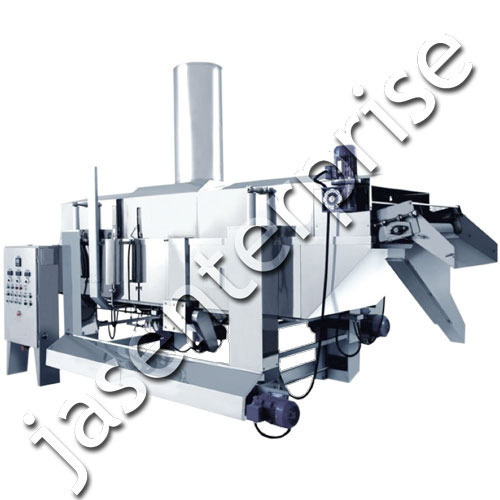

Continuous Frying Systems

Continuous Frying Systems Specification

- Material

- Stainless Steel

- Capacity

- 300 to 350 Kg/hr

- Computerized

- No

- Automatic

- Yes

- Control System

- Manual

- Voltage

- 110-440 Volt (v)

- Power

- 8 Horsepower (HP)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, High Efficiency, Compact Structure

- Warranty

- 1 Year Against Manufacturing Defect At Our Site

Continuous Frying Systems Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 1000 Units Per Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Tripura, Meghalaya, Arunachal Pradesh, Daman and Diu, , South India, Central India, North India, East India, West India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Bihar, Chhattisgarh, Goa, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Madhya Pradesh, Mizoram, Manipur, Nagaland, Pondicherry, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Uttarakhand, West Bengal, Maharashtra, Delhi, Gujarat, Uttar Pradesh, All India

- Certifications

- ISO 9001

About Continuous Frying Systems

Continuous Frying Systems

The multipurpose frying system is exclusively designed for Indian Namkeens and Snacks. Less oil circulates in the system for better oil management and fast turnover. The frying system is proven and working satisfactorily with top brand Namkeen manufacturers of India & abroad.

A Continuous frying system for continuously frying banana chips and other snack foods such as sev, bhujia, Bikaner sev, Ratlami sev, aloo Sev, tomato Sev, spinach sev, Lushan sev, Ganthia, tum tum, nylon sev, sada sev, papadi, ganthia,fulvadi et cetera, Farali chevda, are compact, easily cleaned and serviced, and automatically controlled at an external control Panel. The unit consists of an elongated frying kettle covered by a hood and having, optionally, a slicer at an entrance end. A product delivery conveyor is disposed at an exit end. Twin paddle wheels are provided within the kettle for moving up and down the sliced product as it enters an oil bath therein. Downstream of the paddle wheels a submersion conveyor is provided having depending fries mutually spaced there along for conveying the product through the oil bath to the delivery conveyor at the exit end. The entire product conveyor system, paddle wheels and conveyors may be pivoted upwardly as a unit, out of the kettle, by a linear actuator mounted on the external side thereof. A flexible drive coupling is provided to facilitate this pivotal movement. Oil within the kettle may be re circulated through a heat exchanger. Separately, oil within the kettle may be re circulated through a filter, and an oil level within the kettle is maintained automatically by an internal sensor which controls a filling means.

Standard Capacities (kg/hr):- 150, 250, 500, 750.

- Superior and consistent product

- Better oil management and economics

- Automatic and precise process controls

- Easy installation, simple operation

- Sanitary design

Efficient and Eco-Friendly Performance

Our frying systems deliver exceptional output while maintaining low energy consumption and noise levels, making them a top choice for environmentally conscious food producers. The design enables smooth, continuous operation that ensures a uniform fry and high efficiency.

Robust Stainless Steel Build

Made exclusively from premium stainless steel, these systems are built to withstand rigorous use and guarantee longevity. Their compact structure allows easy integration into different facilities without sacrificing power or capacity.

FAQs of Continuous Frying Systems:

Q: How does the Continuous Frying System operate automatically while still offering manual control?

A: The system is equipped with mechanisms that automate the frying process, such as conveyor belts and preset temperature controls. However, operators can manually intervene to adjust settings for different food products, ensuring flexibility and consistent results.Q: What capacity can this frying system handle per hour?

A: This model is capable of processing between 300 to 350 kilograms of food per hour, which is suitable for medium to large-scale production environments seeking rapid throughput and reliable performance.Q: When is the best time to perform routine maintenance on this system?

A: Routine maintenance is best scheduled after daily operation and during downtime, ensuring all components are cleaned and checked to prevent build-up and mechanical wear. The stainless steel build makes cleaning particularly straightforward.Q: Where can the Continuous Frying System be installed within a facility?

A: Thanks to its compact structure, the system can be installed in most industrial kitchens or food production plants, fitting into existing layouts without requiring significant remodeling. Its suitable for use by manufacturers, suppliers, or retailers across India.Q: What is the process for warranty claims if a manufacturing defect occurs?

A: In the case of a manufacturing defect within the first year, the warranty allows claims to be made directly at the installation site. Our support team will assess and address eligible faults as per warranty terms to minimize operational disruption.Q: How does the system provide lower energy consumption and high efficiency?

A: Advanced engineering reduces energy usage by optimizing heat distribution and using power-efficient components. This design ensures food is fried evenly with minimal waste, supporting eco-friendly practices and cost savings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Namkeen Making Machine Category

Namkeen Mixture Making Machine

Price Range 50000.00 - 125000.00 INR / Unit

Minimum Order Quantity : 01 Unit

Automatic : Yes

Capacity : 300600 Kg/hr

Voltage : 220240V

Rectangular Batch Fryers

Price 50000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Other, Semi Automatic

Capacity : 100500 kg/hr

Voltage : 220380 V

Farsan Making Machine

Price 22000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Capacity : 25200 Kg/hr

Voltage : 230/440 Volt (v)

Chakli Making Machine

Price 75000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Capacity : 50100 Kg/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free