Snacks Making Line

Price 350000.00 INR/ Unit

Snacks Making Line Specification

- Material

- Stainless Steel

- Capacity

- 100 TO 300 Kg/hr

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Voltage

- 440 Volt (v)

- Power

- 5-20 Horsepower (HP)

- Feature

- Lower Energy Consumption, ECO Friendly, Low Noice, High Efficiency, Compact Structure

- Warranty

- 1 Year Against Manufacturing Defect At Our Site

Snacks Making Line Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 1000 Units Per Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Africa, Central America, South America, Asia

- Main Domestic Market

- Chandigarh, Mizoram, Meghalaya, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Haryana, Himachal Pradesh, Jammu and Kashmir, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, , South India, North India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Delhi, Goa, Gujarat, West Bengal, Bihar, Central India, Jharkhand, Chhattisgarh, Uttar Pradesh, All India

- Certifications

- ISO 9001

About Snacks Making Line

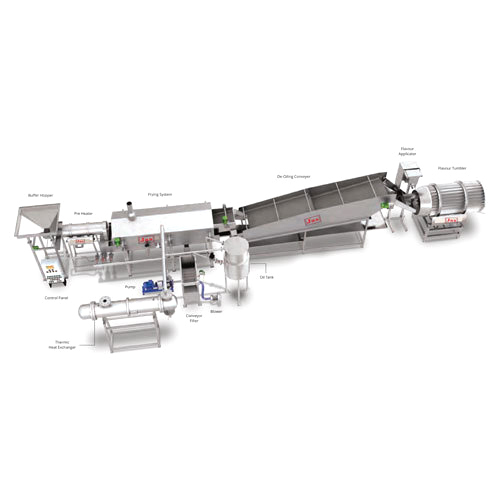

Snacks Making Line

Being well-equipped with the latest technology machinery & equipment and supported by a team of professionals, we are engaged in manufacturing and supplyingSnacks Making Line. This machine is manufactured under the firm guidance of expert supervisors using high quality materials. To provide a defect free range, we check this machine on construction and performance parameters. Clients can obtain this Vermicelli Making Machine in different designs and finishing from Made in India Product

Advanced Automation and Control

Empowered by PLC-based control and computerized settings, the Snacks Making Line ensures precision in every step of production. The system enables easy monitoring and adaptation, making it suitable for frequent recipe changes and varied output requirements. High-degree automation minimizes manual interventions and boosts overall productivity.

Sustainable and Efficient Production

With emphasis on eco-friendliness and lower energy consumption, this production line supports responsible manufacturing practices. The stainless steel build not only enhances hygiene and durability but also simplifies cleaning processes. Its compact design further maximizes workspace utilization.

FAQs of Snacks Making Line:

Q: How does the Snacks Making Line benefit from PLC control and computerized operations?

A: PLC control and computerized operations allow for precise management of each production stage, increasing efficiency and reliability. Operators can easily adjust parameters to accommodate different snack types, reduce errors, and optimize quality with limited manual oversight.Q: What materials are used in the construction of the Snacks Making Line, and why are they important?

A: The line is constructed using stainless steel, which is crucial for maintaining hygiene, resisting corrosion, and ensuring product safety in food processing environments. Stainless steel also contributes to the equipments durability and ease of cleaning.Q: When should maintenance be performed on the Snacks Making Line, and what is covered under the warranty?

A: Regular maintenance should be scheduled as per the manufacturers recommendations, typically after a certain number of production cycles. The one-year warranty covers remedying manufacturing defects at the installation site, providing peace of mind for the operator.Q: Where can the Snacks Making Line be installed, and what makes its structure advantageous?

A: Its compact structure allows installation in production spaces with limited room, making it suitable for small, medium, and large-scale facilities. The ability to maximize workspace usage is a notable advantage for factories in urban or constrained environments.Q: What is the process for producing snacks using this line, and how are its features leveraged?

A: The production process involves automated ingredient dosing, mixing, forming, cooking or baking, and packaging, all controlled by the PLC system. Features like lower energy consumption, low noise, and eco-friendly operation ensure efficient and sustainable output.Q: How much snack output does the line deliver, and how is capacity managed?

A: The Snacks Making Line delivers between 100 to 300 kg per hour. Capacity adjustments can be made according to the production demand, simply by modifying operational parameters via the computerized control panel.Q: What are the key benefits of choosing this snacks making line for manufacturers, distributors, and other stakeholders?

A: The main benefits include high efficiency, lower operational costs due to energy savings, compliance with food safety standards, and robust warranty support. Its automation and flexibility make it suitable for distributors, traders, retailers, and wholesalers seeking reliable snack production solutions in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Namkeen Making Machine Category

Centrifugal Namkeen Dryer Machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Capacity : 50 Kg

Voltage : 215440 Volt (v)

Chana Jor Garam Making Machine / Chana - Moong Pressing Machine

Price Range 100000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : No

Capacity : 70 to 80 Kg/hr

Voltage : 110440 Volt (v)

Nylon Sev Extruder (Hydraulic)

Price Range 22000.00 - 80000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : No

Capacity : 10 to 100 Kg/hr

Voltage : 110440 Volt (v)

Namkeen Extruder Machine

Price Range 22000.00 - 65000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Capacity : 25 to 200 Kg/hr

Voltage : 110440 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free