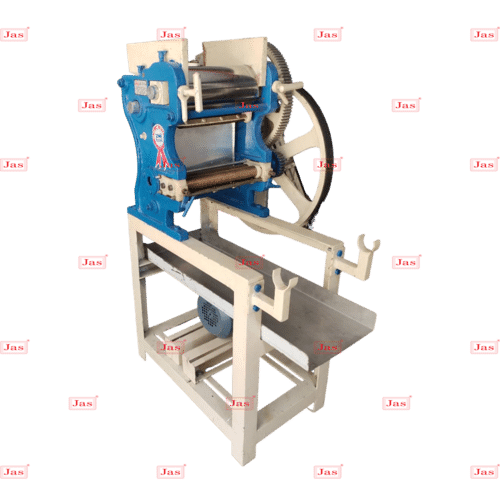

Noodle Extrusion Machine

Price 65000 INR/ Unit

Noodle Extrusion Machine Specification

- Power Source

- Electric

- Automation Grade

- Automatic

- Material

- Stainless Steel

- Capacity

- 50-100 Kg/hr

- Computerized

- No

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Color

- Blue

- Warranty

- 1 Year

Noodle Extrusion Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Noodle Extrusion Machine

-

Ingredients Mixing: The process starts with mixing ingredients, typically flour, water, and sometimes other additives like salt or eggs. This mixture forms a dough or paste.

-

Extrusion Process: The dough is then fed into an extruder, which consists of a barrel and a rotating screw. The screw pushes the dough through a series of chambers, where it is mixed and kneaded.

-

Shaping: As the dough moves through the extruder, it is forced through a die (a metal plate with holes) that shapes it into the desired noodle form. The die can create various noodle shapes and sizes, from thin spaghetti to wide fettuccine.

-

Cutting: After the dough is extruded into the desired shape, it is cut into lengths by a cutting mechanism. This can be done with rotating blades or a knife.

-

Drying/Cooling: The noodles are then cooled or dried, depending on whether they are to be sold fresh or dry. Drying is often done using a hot air oven or a continuous dryer.

-

Packaging: Once the noodles are dried and cooled, they are packaged for distribution.

Key Components of a Noodle Extrusion Machine:

- Feeder System: To supply the dough into the extruder.

- Extruder Barrel and Screw: To mix, knead, and push the dough through the die.

- Die Plate: To shape the dough into noodles.

- Cutting Mechanism: To cut the extruded dough into specific lengths.

- Drying System: For drying the noodles if required.

- Control Panel: To monitor and adjust the machine settings such as temperature, pressure, and speed.

Efficient and Compact Design

Engineered with a focus on energy efficiency and a compact build, the Noodle Extrusion Machine maximizes space utilization while minimizing operational costs. The robust stainless steel structure enhances its lifespan and maintains hygiene, suitable for both small-scale and large-scale facilities.

Low Noise and Eco-Friendly Operation

This machine operates at remarkably low noise levels, providing a comfortable working environment. Its design optimizes energy usage, aligning with environmental standards, and reducing the overall carbon footprint. These features make it an environmentally responsible and employee-friendly choice.

FAQs of Noodle Extrusion Machine:

Q: How does the automatic noodle extrusion process work in this machine?

A: The machine automates the entire noodle production process, including mixing, kneading, and extruding, by using an electric motor and precise mechanical components. Operators simply load the ingredients, select the desired parameters, and the machine continuously extrudes noodles at the set capacity.Q: What materials and voltage is the machine suitable for?

A: Made from high-grade stainless steel, this machine is sturdy and resistant to wear. It operates efficiently with a voltage of either 230 or 440 Volts, making it adaptable for different power supply standards across commercial facilities in India.Q: When should maintenance be performed on the machine?

A: Routine maintenance, such as cleaning and inspection of components, should be conducted every few weeks, or more frequently if operating continuously. The included one-year warranty covers manufacturer defects and helps ensure uninterrupted performance.Q: Where can businesses in India acquire this noodle extrusion machine?

A: The machine is readily available through distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers throughout India. Support services are accessible for installation and after-sales inquiries.Q: What is the typical usage of this noodle extrusion machine?

A: It is commonly used in commercial kitchens, food processing units, and medium-to-large scale noodle manufacturing plants to produce noodles efficiently and hygienically. The automatic system allows for high output with minimal labor.Q: What benefits does this noodle extrusion machine offer to users?

A: Key advantages include high production efficiency, reduced energy consumption, low operational noise, compact space requirements, easy operation, and eco-friendly performance, making it both cost-effective and sustainable for businesses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Noodle Processing Machines Category

Noodle Steaming Machines

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Capacity : 10 to 100 Kg/hr

Material : Cast Iron

Computerized : No

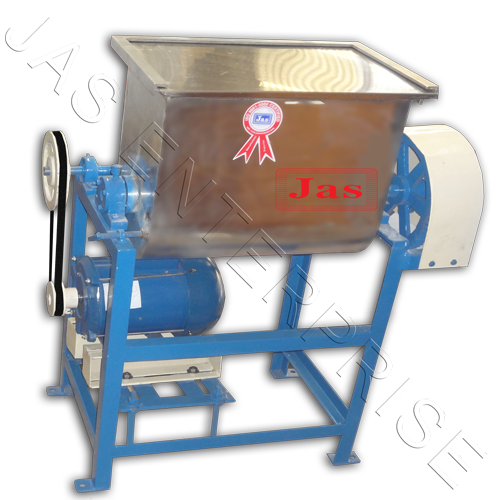

Noodle Flour Mixers

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Yes

Capacity : 10 to 200 Kg/hr

Material : Stainless Steel

Noodle Dryers

Price 50000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Capacity : 10 to 200 Kg/hr

Material : Stainless Steel

Computerized : Yes

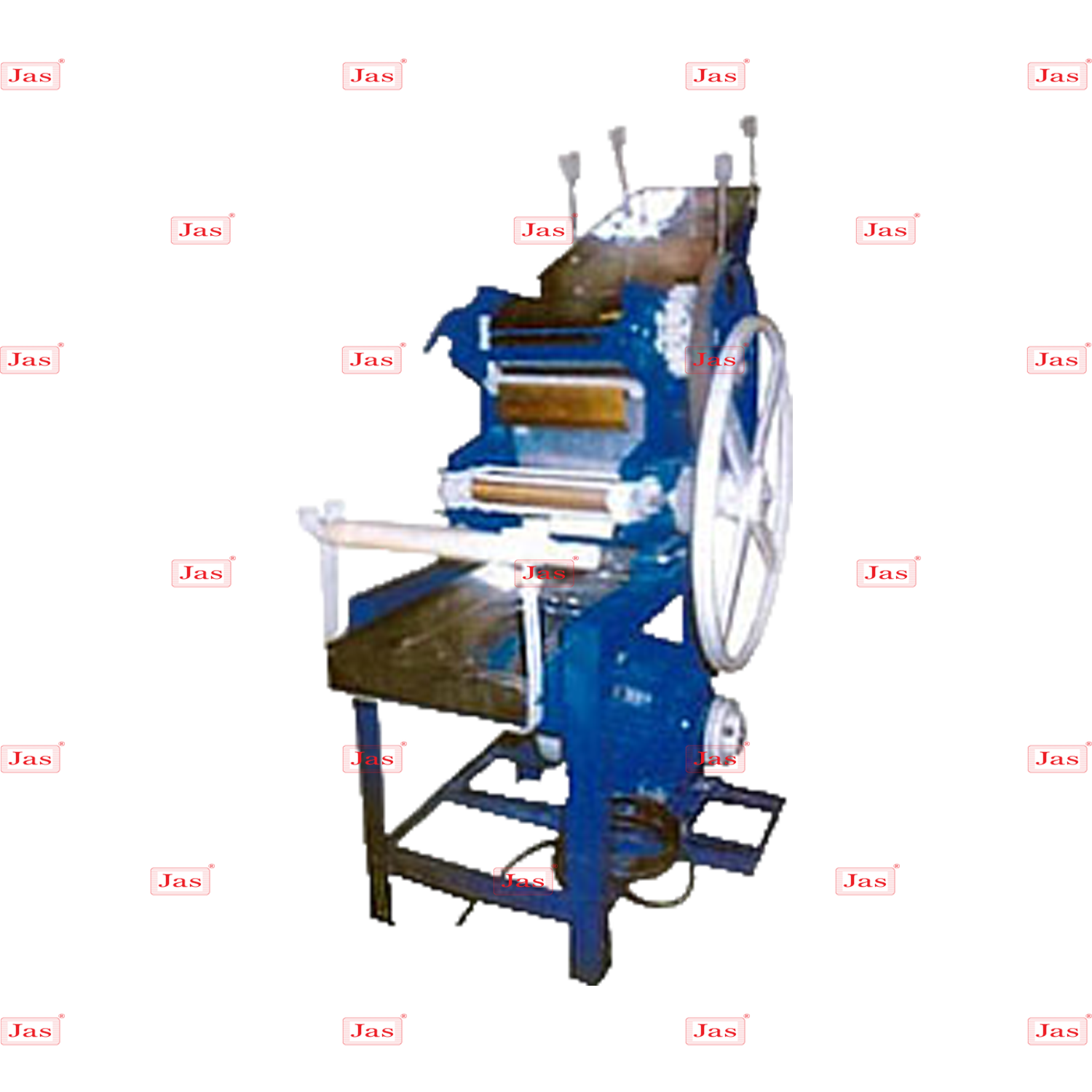

Noodles Extruder Machine

Minimum Order Quantity : 1 Unit

Automatic : Yes

Capacity : 50 to 100 Kg/hr

Material : Stainless Steel

Computerized : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS