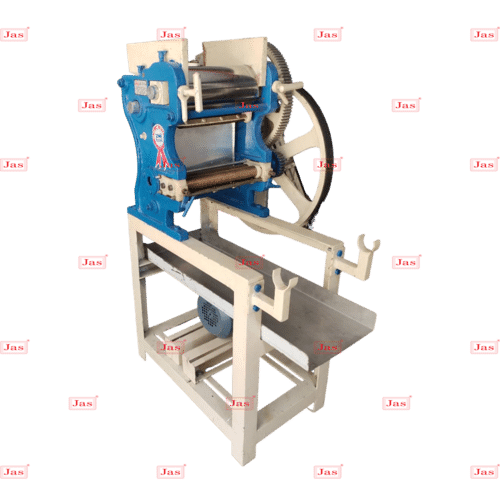

Noodle Steaming Machines

Price 5000 INR/ Unit

Noodle Steaming Machines Specification

- Feeding System

- Manual/Automatic

- Power Source

- Electric

- Frequency

- 50/60 Hz

- Features

- Energy Saving, Easy Operation

- Phase

- Single/Three Phase

- Machine Type

- Food Processing Machine

- Function Type

- Steaming

- Automation Grade

- Automatic

- Noise Level

- Low (<60 dB)

- Heating Method

- Steam/Direct Heat

- Operating Temperature

- 80C - 120C

- Speed Mode

- Variable

- Product Type

- Noodle Steaming Machine

- General Use

- Steaming Noodles

- Material

- Cast Iron

- Type

- Industrial Food Steamer

- Capacity

- 10 to 100 Kg/hr

- Weight (kg)

- 150 kg

- Product Shape

- Rectangular

- Computerized

- No

- Automatic

- Yes

- Control System

- Manual / Electric

- Installation Type

- Floor Mounted

- Voltage

- 220V - 380V

- Power

- 2.5 kW - 7 kW

- Dimension (L*W*H)

- 1200 x 600 x 850 mm

- Raw Material

- Wheat / Rice / Flour

- Feature

- High Efficiency, Corrosion Resistant

- Color

- Stainless Steel / Customized

- Safety Device

- Overheat Protection

- Steam Pressure

- 0.06-0.08 MPa

- Cleaning System

- Removable Tray

- Surface Treatment

- Polished

- Tray Material

- Stainless Steel

- Control Panel

- Digital Display

- Water Consumption

- 20-40 Liters/hr

- Packaging Type

- Wooden Box

- Suitable for

- Hotels, Restaurants, Food Factories

Noodle Steaming Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Months

- Main Domestic Market

- All India

About Noodle Steaming Machines

Gained prominence with the years of experience, we are engaged in manufacturing and exporting tough built Noodle Steaming Machines. These machines are widely used in food processing industry. As per the preferences of clients, these machine are designed into various grades, sizes and models. These machines are engineered employing cutting edge technology, techniques and equipment in order to attain complete customer satisfaction. We deliver these Noodle Steaming Machines with the help of our reliable carriage & freight personnel within the time specified.Striking attributes:

- Rugged construction

- Less energy consumption

- Seamless finish

- Longer service life

Other details:

We serve our customers by the unique range of noodle steaming machine. This product is available in different sizes and gives classy performance in order to satisfy customer needs with perfect technology, compact structure. All contacting parts are made from finest quality of stainless steel 304. We offer our product at competitive prices to make them available for the customers of each class. The noodle produced by this machine is very easy to be saturated by water.

Steamed noodles are partially cooked by treating fresh noodles with either saturated or unsaturated steam before they are marketed. Steamed noodles are prepared using a semi automatic steamer. Fresh raw noodle strands of 2-3 meter in length are hung on rods in a steaming is widely used in noodle processing. The degree of cooking depends on the original moisture content of the noodle; the amount, pressure and temperature of the steam; and steaming time.

Standard accessories of Noodle steaming Machine

Cutting-edge Efficiency for Busy Environments

Engineered for high-throughput operations, this noodle steaming machine provides consistent results for restaurants, food factories, and hotels. Its automatic features and variable speed modes ensure swift processing, supporting capacities up to 100 kg/hr with minimal energy consumption.

Advanced Safety and Intelligent Control

Equipped with overheat protection and a responsive digital control panel, the machine offers reliable, safe use in demanding settings. The manual/electric control system and polished stainless steel trays ensure optimal food hygiene and easy, efficient operation.

Superior Construction and User-friendly Design

Crafted from corrosion-resistant cast iron and polished stainless steel, the steamer is built for long-lasting durability. Its floor-mounted installation and compact design (1200 x 600 x 850 mm) make it convenient for spaces where hygiene and functionality are paramount.

FAQs of Noodle Steaming Machines:

Q: How does the noodle steaming machine operate and what raw materials are suitable?

A: The machine operates automatically using either a manual or electric control system and can process wheat, rice, or flour as base raw materials. It utilizes steam or direct heat to ensure thorough, consistent steaming of noodles.Q: What are the advantages of using a stainless steel removable tray?

A: The stainless steel removable tray is not only corrosion resistant but also simplifies the cleaning and maintenance process. This ensures enhanced hygiene and food safety, critical for commercial kitchens and industrial setups.Q: When is the ideal time to carry out maintenance on this machine?

A: It is recommended to perform routine maintenancesuch as tray cleaning and system checksafter each shift or at the end of a production cycle to prolong machine lifespan and ensure reliable, safe operation.Q: Where is installation best suited for this noodle steamer?

A: The machine is designed for floor mounting and is well-suited for commercial spaces like hotels, restaurants, food production plants, or any location that demands high-capacity, efficient noodle steaming.Q: What benefits does the overheat protection device provide?

A: The overheat protection system ensures the machine operates within safe temperature ranges, preventing potential damage to both the steamer and noodles, while also safeguarding operators.Q: How much power and water does the machine require during operation?

A: It consumes between 2.5 kW to 7 kW of power and 20-40 liters of water per hour, offering high output with energy-saving benefits.Q: What process features make this steaming machine efficient for business use?

A: High efficiency is attributed to its automatic control, variable speed modes, and energy-saving heating method, allowing fast steaming cycles with low operating noiseperfect for busy, quality-conscious foodservice environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Noodle Processing Machines Category

Noodle Extrusion Machine

Price 65000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 50100 Kg/hr

Automatic : Yes

Computerized : No

Material : Stainless Steel

Noodle Cutting Machine

Price 50000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 100 per hurs Kg/hr

Automatic : Yes

Computerized : No

Material : Stainless Steel

Noodles Extruder Machine

Minimum Order Quantity : 1 Unit

Capacity : 50 to 100 Kg/hr

Automatic : Yes

Computerized : Yes

Material : Stainless Steel

Noodle Flour Mixer

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 30 to 35 Kg/hr

Automatic : Yes

Computerized : No

Material : Cast Iron

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS