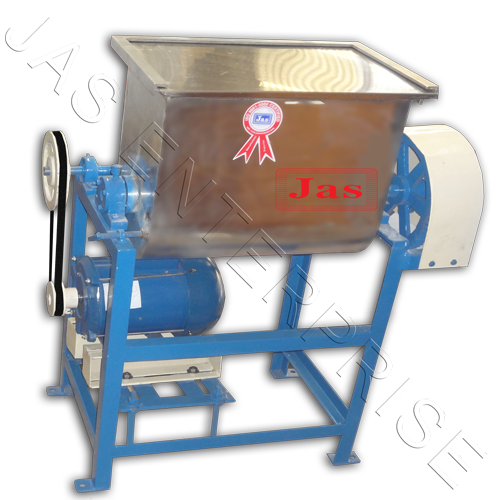

Noodle Flour Mixer

Price 5000 INR/ Unit

MOQ : 1 Unit

Noodle Flour Mixer Specification

- Material

- Cast Iron

- Capacity

- 30 to 35 Kg/hr

- Computerized

- No

- Automatic

- Yes

- Power

- 2000 Watt (w)

- Color

- White

- Warranty

- 1 year

Noodle Flour Mixer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Months

About Noodle Flour Mixer

Our company is deemed as one of the leading manufacturers and exporters of robustly built Noodle Flour Mixer. This mixer is engineered using superior quality raw materials and other components that are procured from credited vendors of the market. In order to attain complete customer satisfaction, this mixer is stringently checked on various factors like seamless finish and excellent performance. Noodle Flour Mixer is ideal for the production of flour and food items.

Striking features:

- Less maintenance

- Longer functional life

- Superior finish

- Sturdy construction

Other details:

Mixing formula ingredients is often carried out in a horizontal flour mixer for 10-15 minutes. Since the horizontal mixer seems to have better mixing results in commercial noodle production. Mixing results in the formation of a crumbly dough with small and uniform particle sizes. Since the water addition level is relatively low (vs. Bread dough), gluten development in noodle dough during mixing is minimized. This improves the dough sheet ability, sheeted dough smoothness and uniformity. Limited water absorption also slows down noodle discoloration and reduces the amount of water to be taken out during the final drying or frying processes.The paddles are positioned to move the material in opposing lateral directions as well as radically. The paddle design is generally employed where friable materials are being blended.

Horizontal noodle dough mixer consists of several elements: a centrally mounted horizontal shaft that rotates within a cylindrical container, paddles, ploughs mixing elements that are attached to the centrally mounted shaft, special openings at the top for feeding materials, manually tilt able tank operated, inside a cylindrical conduit and a complete drive unit.

Efficient Mixing for Commercial Kitchens

Designed to meet the demands of restaurants and food manufacturers, this Noodle Flour Mixer streamlines the preparation of dough for noodles. Its automatic operation minimizes manual input, allowing chefs to focus on other tasks. The powerful motor and sturdy cast iron build ensure dependable results and long-lasting performance, making it an essential tool for high-volume kitchens.

Versatile, Professional-Grade Construction

Constructed from high-quality cast iron, the Noodle Flour Mixer resists daily wear and maintains consistent performance even with heavy use. Its 30-35 kg/hr capacity accommodates large batches, perfect for commercial operations. The machines automatic function supports efficiency, saving time and reducing labor costs for food businesses in India.

FAQs of Noodle Flour Mixer:

Q: How does the Noodle Flour Mixer enhance efficiency in noodle production?

A: The mixer automates the process of blending flour for noodles, handling up to 35 kg per hour. This reduces manual labor requirements and speeds up noodle preparation, benefiting large kitchens and production facilities.Q: What is the maximum flour capacity the mixer can handle?

A: The Noodle Flour Mixer is designed to handle between 30 to 35 kilograms of flour per hour, making it suitable for medium to large-volume production environments.Q: When should I perform maintenance on the mixer?

A: Regular cleaning after each use is recommended, with detailed inspections monthly. The unit comes with a 1-year warranty to cover unexpected issues, and maintenance schedules can be tailored based on usage frequency.Q: Where can I purchase the Noodle Flour Mixer in India?

A: This mixer is available through various channels including distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers throughout India.Q: What is the process for using this mixer?

A: Simply load the required quantity of flour, set the appropriate settings, and start the automatic mixing cycle. The powerful motor ensures consistent dough texture for noodles with minimal supervision.Q: How does the cast iron material benefit the mixer?

A: Cast iron provides exceptional durability and stability, enabling the mixer to withstand frequent commercial use and ensuring reliable performance over time.Q: What are the advantages of the mixer being automatic but not computerized?

A: As an automatic, non-computerized machine, the mixer combines ease of use with robust reliability, reducing potential electronic failures and simplifying operation for all staff members.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Noodle Processing Machines Category

Noodle Steaming Machines

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Material : Cast Iron

Computerized : No

Capacity : 10 to 100 Kg/hr

Noodle Flour Mixers

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Yes

Material : Stainless Steel

Capacity : 10 to 200 Kg/hr

Noodle Cutting Machine

Price 50000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Material : Stainless Steel

Computerized : No

Capacity : 100 per hurs Kg/hr

Noodle Dryers

Price 50000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Material : Stainless Steel

Computerized : Yes

Capacity : 10 to 200 Kg/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS