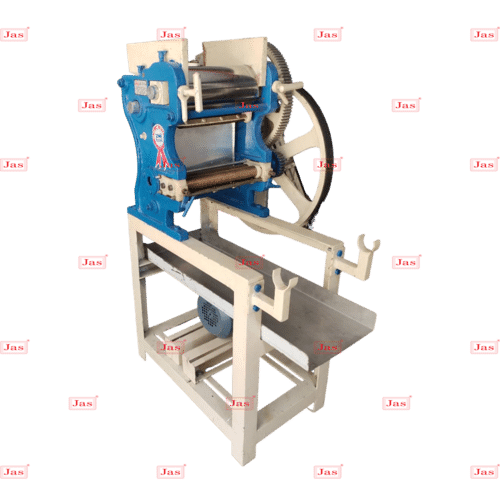

Noodle Cutting Machine

Price 50000 INR/ Unit

MOQ : 1 Unit

Noodle Cutting Machine Specification

- Material

- Stainless Steel

- Capacity

- 100 per hurs Kg/hr

- Computerized

- No

- Automatic

- Yes

- Installation Type

- Free Stand

- Voltage

- 110 to 440 Volt (v)

- Feature

- Lower Energy Consumption, ECO Friendly, Low Noice, High Efficiency, Compact Structure

- Warranty

- One year against manufacturing defects at our site

Noodle Cutting Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahemadabad

- Supply Ability

- 1000 Units Per Month

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Lakshadweep, South India, North India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Delhi, Gujarat, Uttar Pradesh, Bihar, Kerala, Central India, Odisha, Chhattisgarh, All India

- Certifications

- ISO 9001

About Noodle Cutting Machine

Being well-equipped with the latest technology machinery & equipment and supported by a team of professionals, we are engaged in manufacturing and supplying Noodle Cutting Machine. This machine is manufactured under the firm guidance of expert supervisors using high quality materials. To provide a defect free range, we check this machine on construction and performance parameters. Clients can obtain this Vermicelli Making Machine in different designs and finishing from us.Premium Quality and Durability

Built with robust stainless steel, the Noodle Cutting Machine ensures long-lasting durability and resistance to corrosion. Its compact, free-standing design allows for simple integration into existing production lines. The machines automatic operation delivers consistently precise noodle cuts with minimal effort, making it an ideal addition for manufacturers and suppliers in the food industry.

Efficient and Eco-Friendly Performance

High efficiency is at the core of this noodle cutting machine, processing up to 100 kg of noodles per hour. It is engineered for lower energy consumption and reduced noise levels, supporting a quieter and more sustainable work environment. The combination of eco-friendly design and economical power usage enhances cost-effectiveness for food processors.

FAQs of Noodle Cutting Machine:

Q: How does the automatic noodle cutting machine operate for large-scale production?

A: The automatic noodle cutting machine processes up to 100 kg of noodles per hour with minimal manual intervention. Once powered on and loaded with dough, it automatically cuts noodles to consistent sizes, streamlining production and maximizing efficiency for large-scale operations.Q: What are the main benefits of using this noodle cutting machine in commercial kitchens or factories?

A: The machine boasts lower energy consumption, high efficiency, and low noise production. Its compact structure saves space, and its stainless steel construction ensures durability. Additionally, being eco-friendly and fully automatic, it reduces labor costs and enhances production output.Q: Where can this noodle cutting machine be installed, and does it require any special setup?

A: This free-standing unit can be installed in various settings, such as commercial kitchens, food processing factories, and noodle production facilities. It does not require any fixed installation or complex setup, making it convenient and adaptable for different environments.Q: What is the process for operating and maintaining the machine?

A: Operation is straightforwardsimply connect the machine to a power supply (compatible from 110 to 440 volts), load the dough, and allow the automatic system to cut the noodles. For maintenance, regular cleaning and periodic checks for wear are recommended. The one-year warranty covers any manufacturing defects that may arise.Q: When would it be advisable to use this machine over manual noodle cutting methods?

A: This machine is ideal when consistency, speed, and high-volume output are priorities. Its automated operation saves time and energy compared to manual methods, making it a practical choice for large-scale noodle producers or businesses looking to boost productivity.Q: In what ways is the noodle cutting machine environmentally friendly?

A: The machine is designed for lower energy consumption, which reduces electricity usage and operational costs. It also operates with low noise, contributing to a healthier work environment. These features align with environmentally responsible production practices.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Noodle Processing Machines Category

Noodle Extrusion Machine

Price 65000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Material : Stainless Steel

Capacity : 50100 Kg/hr

Computerized : No

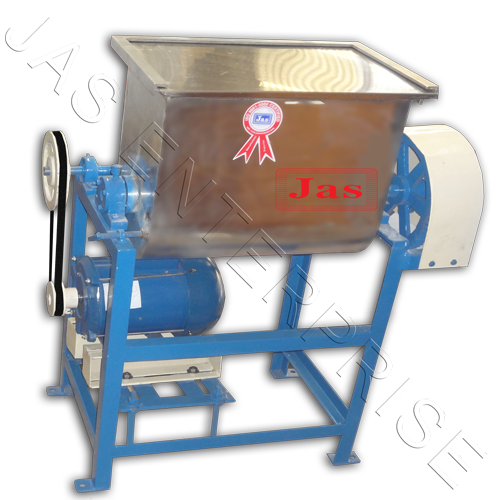

Noodle Flour Mixers

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Yes

Material : Stainless Steel

Capacity : 10 to 200 Kg/hr

Noodle Dryers

Price 50000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Material : Stainless Steel

Capacity : 10 to 200 Kg/hr

Computerized : Yes

Noodle Flour Mixer

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Material : Cast Iron

Capacity : 30 to 35 Kg/hr

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free