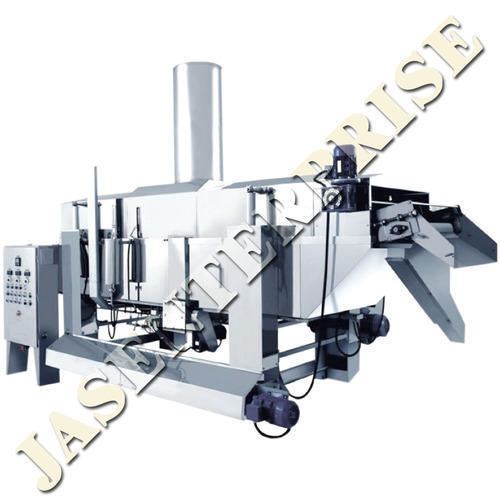

Semi Automatic potato Chip making Line

Price 120000.00 INR/ Piece

MOQ : 1 Unit

Semi Automatic potato Chip making Line Specification

- Automation Grade

- Semi Automatic

- Frequency

- 50-60 Hertz (HZ)

- Phase

- Single Phase / Three phase

- Capacity

- 200-1000 Kg/hr

- Voltage

- 230/440 Volt (v)

- Warranty

- One year against manufacturing defect at our side

Semi Automatic potato Chip making Line Trade Information

- Minimum Order Quantity

- 1 Unit

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Semi Automatic potato Chip making Line

The Semi-Automatic Potato Chip Making Line is a highly efficient and cost-effective production system designed for small to medium-scale potato chip manufacturers. It combines the reliability of mechanized processes with the flexibility of manual handling, offering an excellent balance between automation and operator control. This type of line is ideal for startups, small food processing units, and entrepreneurs looking to enter the snack food industry with moderate investment.Versatile Production Capacity

This potato chip making line is capable of processing between 200 and 1000 kilograms per hour. Its semi-automatic operation reduces manual labor while ensuring control over each stage of the chip-making process. Whether youre scaling up or starting fresh, this flexibility helps you align production with market demands.

Simple Operation and Maintenance

The user-friendly design of our semi automatic line allows for easy training and routine maintenance. The system runs on standard 230/440V power and works well with both single and three-phase supply, offering consistent performance across various setups found in Indian industries.

FAQs of Semi Automatic potato Chip making Line:

Q: How is the semi automatic potato chip making line operated?

A: The line combines both manual and automated operations, allowing users to monitor key stages and intervene as needed, while most repetitive processes are handled automatically for efficiency.Q: What is the power requirement for this chip making line?

A: It operates on a voltage of either 230 or 440 volts and is compatible with both single and three-phase electrical setups, with a frequency range of 50-60 Hz.Q: When should routine maintenance be performed on the line?

A: Regular cleaning after each production cycle is recommended, with more thorough checks on mechanical and electrical components suggested every three months to ensure optimal performance.Q: Where can this line be installed in India?

A: Suitable for installation at manufacturing plants, food processing units, and commercial kitchens throughout India, it is designed with flexible phase and voltage compatibility.Q: What is the typical process flow for making potato chips with this line?

A: Potatoes are first washed and peeled, then sliced, washed again, blanched, fried, and finally de-oiled using the lines semi automated system, resulting in consistently high-quality chips.Q: How does this line benefit snack manufacturers?

A: It increases production efficiency, reduces manual labor, and ensures uniform product quality, helping manufacturers and suppliers meet market demand more reliably.Q: Is warranty support included with purchase?

A: Yes, the line comes with a one-year warranty covering manufacturing defects, providing assurance to buyers and support for uninterrupted operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Potato Chips Making Machines Category

Potato Peelers

Price Range 15000.00 - 90000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110440 Volt (v)

Capacity : 5 to 50 Kg/hr

Fully Automatic Potato Chips Plant

Price Range 8000000.00 - 12500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110440 Volt (v)

Capacity : 200 TO 500 Kg/hr

Wafer Making Machine

Price 25000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 230/440 Volt (v)

Capacity : 40180 Kg/hr

Potato Chip Line

Price 65000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110440 Volt (v)

Capacity : 100 TO 500 Kg/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS