Vegetable Dehydration Plants

Price 390000 INR/ Unit

Vegetable Dehydration Plants Specification

- Capacity

- 30-2500 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Vegetable Dehydration Plants Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Vegetable Dehydration Plants

-

Preparation: Vegetables are harvested and brought to the dehydration plant. They undergo initial cleaning and sorting to remove any debris or damaged pieces.

-

Cutting and Slicing: Depending on the type of vegetable and its intended use, it may be cut or sliced into uniform pieces. This step helps in achieving consistent drying times and quality.

-

Blanching: Some vegetables may undergo blanching, where they are briefly heated in boiling water or steam. Blanching helps in stabilizing color, preserving nutrients, and improving drying efficiency by softening the tissues.

-

Dehydration: The main process involves removing moisture from the vegetables. This can be achieved through various methods:

- Air Drying: Vegetables are placed in trays or on conveyor belts and subjected to hot air circulation.

- Freeze Drying: Involves freezing the vegetables and then reducing the surrounding pressure to allow the frozen water to sublimate directly from ice to vapor.

- Vacuum Drying: Vegetables are placed in a vacuum chamber where the pressure is reduced, and heat is applied to evaporate moisture.

-

Cooling: Once sufficiently dried, the vegetables are cooled to room temperature to prevent moisture absorption.

-

Packaging: Dehydrated vegetables are then packaged in airtight containers or vacuum-sealed bags to maintain their quality and shelf life.

-

Quality Control: Throughout the process, quality control measures are implemented to ensure that the vegetables meet safety standards, maintain their nutritional content, and achieve the desired moisture content.

Benefits of vegetable dehydration plants include reduced waste (since dehydrated vegetables have a longer shelf life), easier storage and transportation, and the ability to use vegetables year-round even when they are out of season.

Eco-Friendly and Efficient Dehydration

Our vegetable dehydration plants are engineered to minimize environmental impact. By utilizing lower energy consumption and operating with high efficiency, these systems help reduce your carbon footprint while maximizing output. The compact structure also allows installation in space-restricted environments without compromising performance.

Flexible Voltage and Capacity Options

Designed for adaptability, the plant offers voltage selections of either 230 or 440 Volt, suiting various operational setups. The large processing range of 30 to 2500 kg per hour meets the needs of both small businesses and large-scale operations, ensuring versatility and optimal productivity for vegetable dehydration.

FAQs of Vegetable Dehydration Plants:

Q: How does the vegetable dehydration plant help save energy and reduce operational costs?

A: This plant is engineered for lower energy consumption while delivering high efficiency, significantly reducing utility expenses. Its automated features and eco-friendly design ensure minimal resource wastage, making it a cost-effective solution for vegetable processing.Q: What is the process of dehydrating vegetables with this plant?

A: Vegetables are loaded into the automated system, where controlled heat and airflow remove moisture while preserving nutritional and sensory quality. The process is efficient and minimizes human intervention, allowing consistent results and rapid throughput.Q: When is vegetable dehydration recommended using this plant?

A: Vegetable dehydration is ideal when there is a need to extend shelf life, facilitate easy transportation, or mitigate wastage due to surplus produce. The plant operates reliably for continuous or seasonal use based on production needs.Q: Where can I install a vegetable dehydration plant in India?

A: The compact structure and flexible voltage options allow installation in various locationssuch as processing units, food factories, farms, or warehouses. Indian suppliers, distributors, exporters, manufacturers, retailers, traders, and wholesalers can assist with local accessibility and support.Q: What are the usage benefits of an automatic vegetable dehydration plant?

A: Users benefit from streamlined, hands-free operation, reduced labor costs, and consistent product quality. The low-noise feature ensures a comfortable working environment, while high efficiency and large capacity accommodate diverse business scales.Q: How does the compact design contribute to better plant management?

A: The compact structure enables efficient use of available space and simplifies maintenance. It is particularly advantageous in facilities where floor area is limited or needs to be optimized for multiple operations.Q: What advantages do Indian suppliers offer for vegetable dehydration plants?

A: Indian suppliers provide easy access to spare parts, timely support, and customization services. Their local presence ensures prompt assistance and competitive pricing for buyers nationwide.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Shakkar Para Nimki Making Machine

Minimum Order Quantity : 1 Unit

Capacity : 5 to 500 Kg/hr

Voltage : 110440 Volt (v)

Automatic : Yes

Warranty : 1 Year Against Manufacturing Defect At Our Site

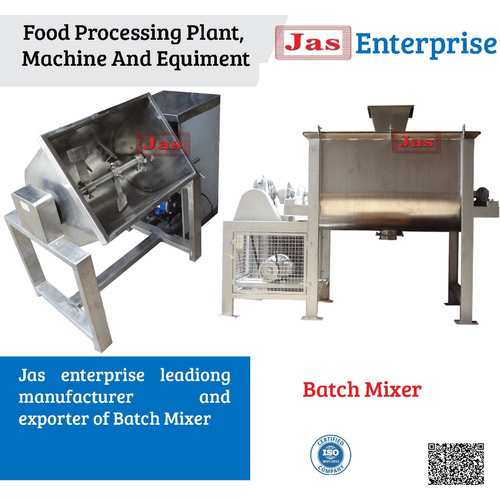

Batch Mixers

Price 27000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 500 kgs Kg/day

Voltage : 110 to 440 Volt (v)

Automatic : Yes

Warranty : One year against manufacturing defects at our site

Copra Cutter

Price 11000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 30 kg/Hr Kg/hr

Voltage : 110 to 440 Volt (v)

Automatic : Yes

Warranty : One year against manufacturing defects at our site

Onion Processing Machine

Price 550000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : 302500 Kg/hr

Voltage : 230/440 Volt (v)

Warranty : One year against manufacturing defect at our side

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS