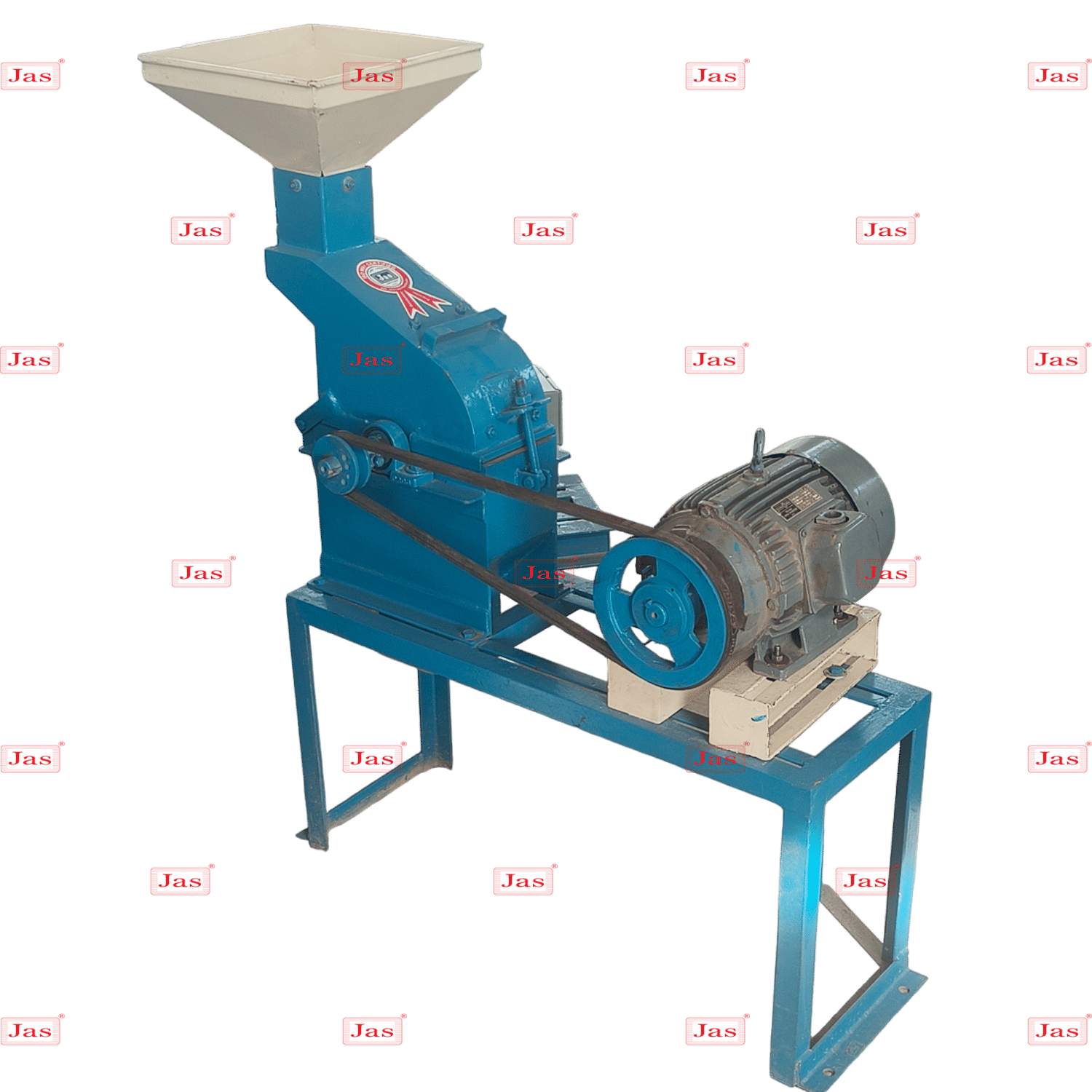

WoodHammerMill machine

Price 18000 INR/ Unit

WoodHammerMill machine Specification

- Capacity

- 20-2200 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

WoodHammerMill machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About WoodHammerMill machine

-

Function: The hammer mill shreds wood by repeatedly striking it with hammers. This process reduces the size of the wood particles, making them suitable for use in various applications like animal feed, biomass fuel, and wood pellets.

-

Components: Major components include the hammers, screen (which controls the size of the output particles), and the rotor (which drives the hammers). The size of the output can be adjusted by changing the screen size or hammer configuration.

-

Types: There are several types of hammer mills, including gravity-fed and pneumatic (air-powered) models. Gravity-fed models allow the wood to fall into the mill by gravity, while pneumatic models use air pressure to move the material.

-

Applications: Wood hammer mills are used in agriculture for processing animal feed, in the timber industry for creating wood chips and sawdust, and in renewable energy sectors for producing biomass fuel.

-

Maintenance: Regular maintenance is necessary to keep the hammer mill running efficiently. This includes checking and replacing worn-out hammers, screens, and other components, as well as ensuring proper lubrication.

High Efficiency and Eco-Friendly Operation

Designed with advanced technology, the Wood Hammer Mill achieves high output while minimizing environmental impact. Its lower energy consumption and low noise operation make it ideal for businesses seeking sustainable and cost-effective manufacturing processes.

Wide Application and Flexible Capacity

With a capacity span from 20 to 2200 Kg/hr, this hammer mill adapts seamlessly to varying production requirements. Its automatic features streamline wood processing, meeting the needs of distributors, retailers, suppliers, and wholesale traders throughout India.

FAQs of WoodHammerMill machine:

Q: How does the Wood Hammer Mill machine operate automatically?

A: The Wood Hammer Mill is equipped with automated controls that facilitate continuous feeding and efficient grinding of wood, reducing manual intervention and optimizing productivity.Q: What are the main benefits of using this Wood Hammer Mill?

A: Key benefits include high efficiency, eco-friendly operation, low noise generation, and reduced energy consumption, making it an economical and sustainable choice for wood processing businesses.Q: When should I choose a machine with a capacity of up to 2200 Kg/hr?

A: Select a higher-capacity model when your production requirements involve large-scale wood processing, such as in industrial biomass plants or bulk furniture manufacturing facilities.Q: Where can I purchase or source the Wood Hammer Mill in India?

A: The Wood Hammer Mill is available through a wide network of distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers across India, ensuring convenient access and support.Q: What is the process for installing and commissioning the Wood Hammer Mill?

A: Installation typically involves connecting the machine to a suitable 230/440 Volt power source, securing its placement, and calibrating automatic controls. Suppliers often provide guidance and technical support during commissioning.Q: How is wood material used in this machine processed, and what type of output is produced?

A: Wood materials are fed into the hammer mill, where they are crushed into fine particles through high-speed hammers. The output is consistent, finely ground wood suitable for applications in biomass, pulp, and MDF industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding, crushing and Pulverizing Machine Category

Besan Making Machine

Price 28000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 440 Volt (v)

Capacity : 20 to 2000 Kg/hr

Feature : High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Pulses and Grains Grinding Pulverizer

Price 30000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 415 Volt (v)

Capacity : 8 to 80 Kg/hr

Pulverizing Machine

Price 18000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 230/440 Volt (v)

Capacity : 202200 Kg/hr

Feature : High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Pulverizer For Hotel Industry

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : No

Voltage : 230/440 Volt (v)

Capacity : 15450 Kg/hr

Feature : High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free