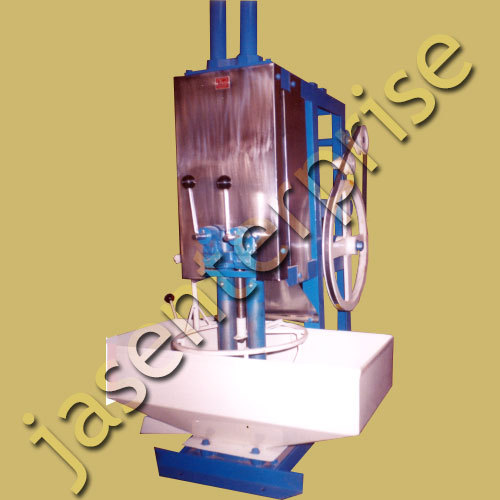

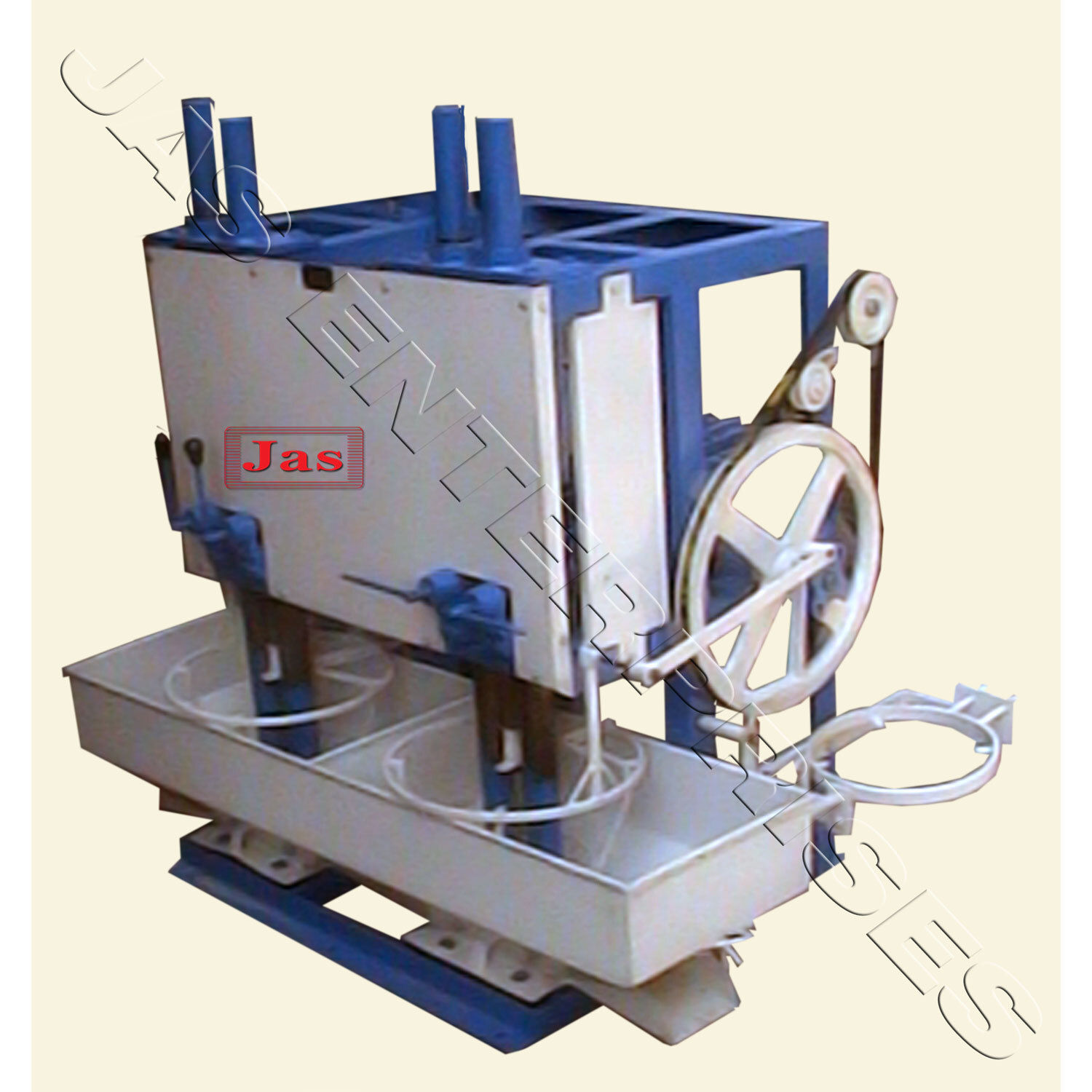

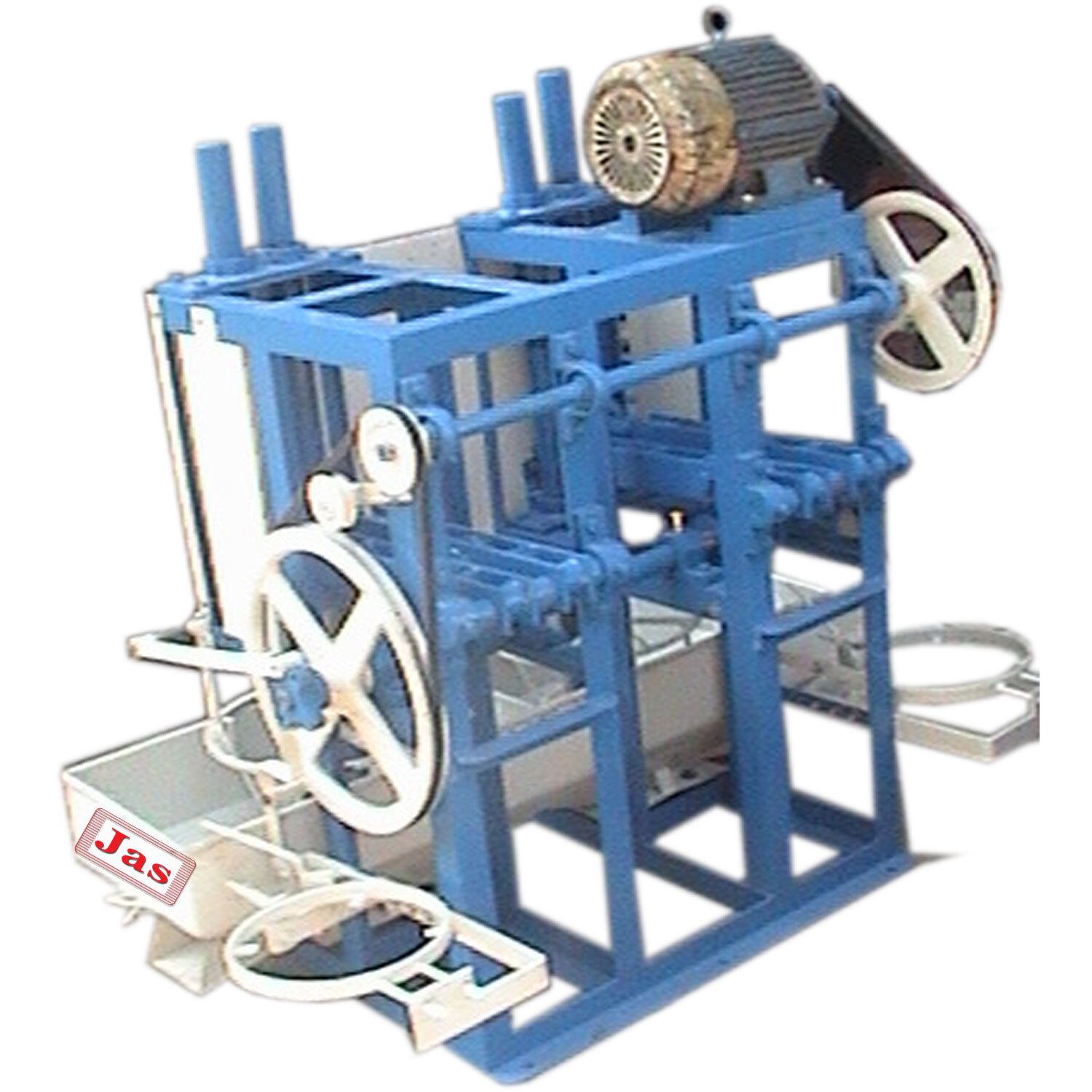

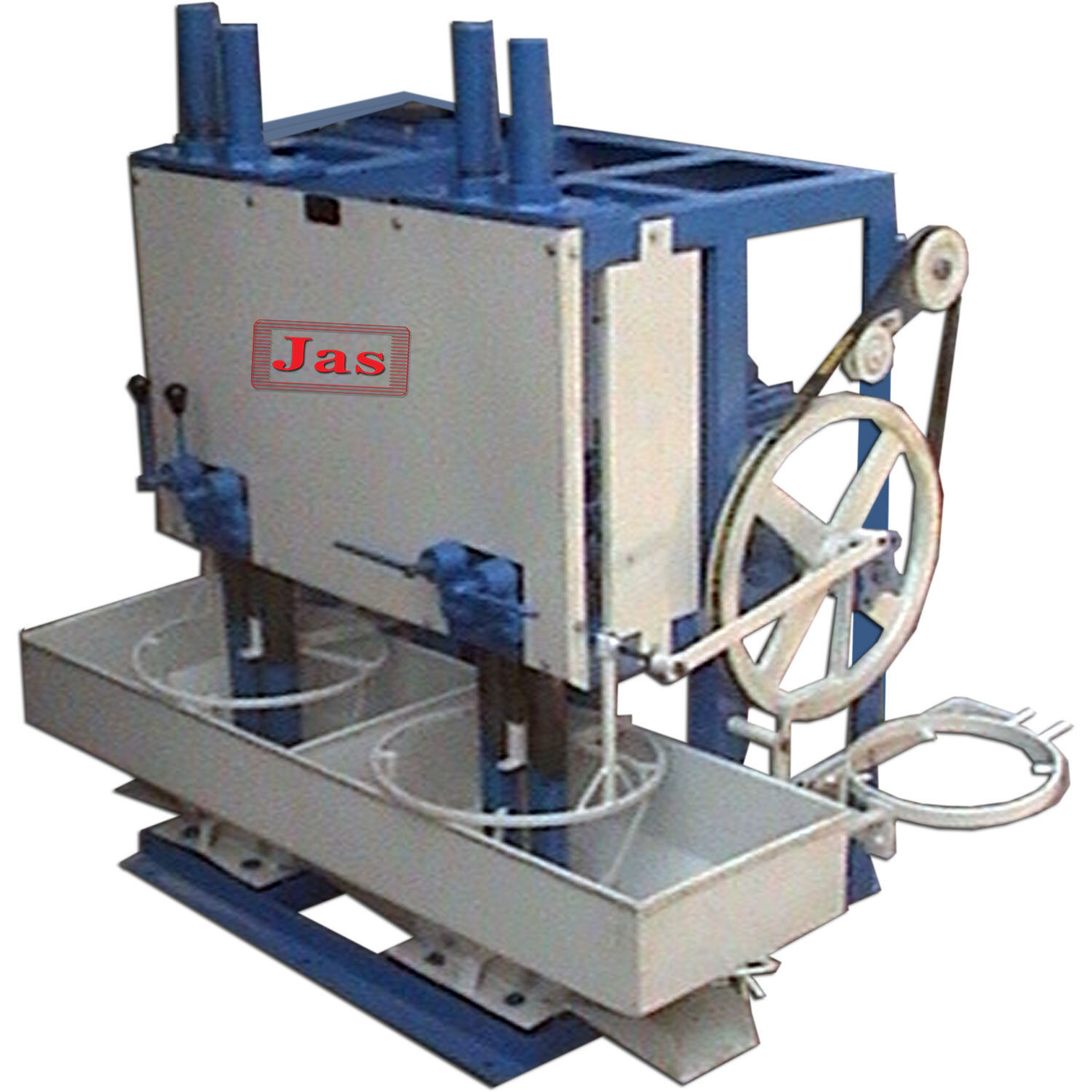

Chilli Pounding Machine

Chilli Pounding Machine Specification

- Material

- Stainless Steel

- Capacity

- 30-35 Kg/hr

- Weight (kg)

- 65 Kilograms (kg)

- Automatic

- Yes

- Power

- 745 - 7457 Watt (w)

- Voltage

- 110 to 415 Volt (v)

Chilli Pounding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Export-worthy packing will be charged extra as applicable at the time of delivery

- Certifications

- ISO 9001 Certified

About Chilli Pounding Machine

Utilizing the knowledge and experience, we have been committed to manufacture and export toughbuilt Chilli Pounding Machine. In order to satisfy the needs of clients, we assure to use one of the best quality stainless steel and other components in the manufacturing process. Our offered machine is stringently checked on various factors like outstanding finish and optimum functionality. This Chilli Pounding Machine is manufactured into various grades, models and specifications.This machine is highly acknowledged for:

- Tough construction

- Longer functional life

- High tensile strength

- Safe operation

Pounding Machine (Kandap Machine)

Pounding machine pound means strike or hit heavily and repeatedly. Jas enterprise offers pounding machine (kandap machine). It is ideal for making powder of spices, herbs and ayurvedic medicines according to traditional methods. It is fitted with cam lever arrangements for extra power to hammer. Automatic stirrer is provided in the chamber to shift the materials while hammering. It is equipped with specially designed liver to lock/unlock the hammering process. Sieving can be done while hammering is locked or stopped. It is provided with fly wheel with pulley for easy smooth operations. Some of its features include less noise, dust free operation, no wastage of product and pollution hazards, low maintenance, etc. Grinding is carried out in a cool atmospheric temperature, which guarantee against any thermal degradation of product quality and flavors. Operating principle of pounding machine a pounding machine consists of a set of heavy steel pounds, loosely held vertically in a frame, in which the pounds can slide up and down. They are lifted by cams on a horizontal rotating shaft. On jas enterprises pounding machine, the cam is arranged to lift the pounds from the side, so that it causes the pound to rotate. As the cam moves from under the pounds, the pounds falls onto the material below, crushing the rock, spices, roots etc and the lifting process is repeated at the next pass of the cam. Jas enterprises specially designed liver to lock/unlock the pounding process. Sieving can be done while hammering is locked or stopped.

Efficient and Hygienic Processing

Built entirely from stainless steel, the Chilli Pounding Machine assures hygiene and longevity. Its automatic operation simplifies the pounding process, making it easy to achieve a consistent product every time, while minimizing physical labor and maintaining cleanliness during production.

Versatile Voltage Compatibility

Accommodating voltage from 110 to 415 volts, this machine can be used in a variety of commercial setups across India. Whether in urban or rural areas, its versatile voltage range supports seamless installation and operation in diverse environments.

FAQs of Chilli Pounding Machine:

Q: How does the automatic Chilli Pounding Machine improve spice processing?

A: The machines automatic function streamlines the pounding process, ensuring consistent and uniform chilli powder. This reduces manual effort, increases output efficiency, and maintains product quality for large-scale operations.Q: What materials are used in manufacturing this chilli pounding machine?

A: The machine is constructed from high-grade stainless steel, which contributes to its durability, hygiene, and resistance to corrosion, making it suitable for food processing industries.Q: When should I consider using this chilli pounding machine in my business?

A: This machine is ideal for businesses that require regular, large-scale chilli powder production, such as spice processing units, commercial kitchens, and food product companies, due to its capacity of 30-35 kg/hr.Q: Where can this machine be installed and operated?

A: With its voltage compatibility ranging from 110 to 415 volts, the machine can be installed in various commercial and industrial locations throughout India, whether in rural or urban settings.Q: What is the process for operating the automatic chilli pounding machine?

A: Operation involves loading whole chillies into the machines hopper, setting the required parameters, and initiating the automatic pounding cycle. The processed spice is collected from the output section, minimizing manual handling.Q: How is the machine maintained for optimal longevity and hygiene?

A: Regular cleaning with food-grade solutions is recommended, focusing on the pounding chamber and output areas. Routine checks for wear and mechanical maintenance will ensure consistent performance and extended service life.Q: What are the key benefits of using this automatic chilli pounding machine for businesses?

A: The primary advantages include high production capacity, significant labor savings, enhanced product quality, and compliance with food safety standards due to its stainless steel construction and automated operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding, crushing and Pulverizing Machine Category

Bottom Discharge Hammer Mill

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 415 Volt (v)

Feature : High Performance, Lower Energy Consumption, Low Noise, ECO Friendly, High Efficiency

Capacity : 3035 Kg/hr

Red Chilli PoundingExporters

Price 41000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 230/440 Volt (v)

Feature : High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Capacity : 820 Kg/hr

Masala Grinding Machine

Price 56000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 230/440 Volt (v)

Feature : High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Capacity : 30160 Kg/hr

WoodHammerMill machine

Price 18000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 230/440 Volt (v)

Feature : High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Capacity : 202200 Kg/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free