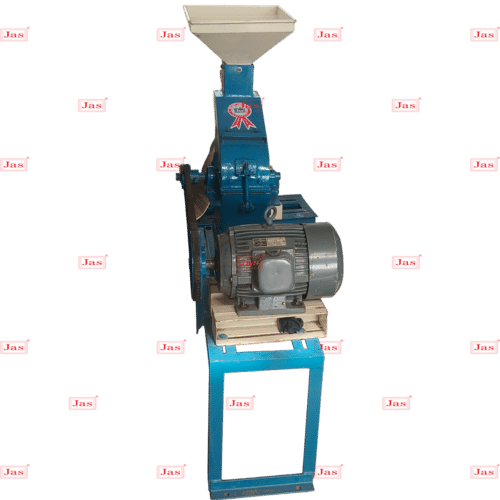

Corn Grinder Machine

Price 18000 INR/ Piece

Corn Grinder Machine Specification

- Capacity

- 20-2200 Kg/hr

- Power

- 2-125 Horsepower (HP)

- Voltage

- 220/440 Volt (v)

- Feature

- High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

- Warranty

- One year against manufacturing defect at our side

Corn Grinder Machine Trade Information

- Minimum Order Quantity

- 1000 Units

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Corn Grinder Machine

A corn grinder machine is a specialized piece of equipment designed to process dried corn kernels into various forms such as flour, grits, or coarse meal. It plays a vital role in agriculture, food processing, and home-based food production. These machines are built to efficiently break down corn into smaller, usable particles for human consumption or animal feed.

Corn grinders can be powered manually, electrically, or by diesel engines, depending on the model and intended use. The core grinding mechanism may involve burr plates, hammers, or rollers, which apply pressure and friction to crush and grind the kernels. The fineness of the output can often be adjusted to suit specific needsïranging from fine corn flour for baking to coarse grit for animal feed or traditional dishes.

Superior Grinding Capacity

Designed for scalability, the Corn Grinder Machine effortlessly processes between 20 and 2200 kilograms per hour. This wide range accommodates varying operational scales, ensuring efficiency and productivity for both small businesses and large industrial enterprises. Its sturdy construction and high-powered motor deliver consistent performance round the clock.

Eco-Friendly and Energy-Efficient Solution

Built with sustainability in mind, this grinder ensures lower energy consumption while maintaining high output. Its eco-friendly features help minimize environmental impact, making it a reliable choice for responsible businesses. Operate efficiently with reduced noise levels, contributing to a better workplace environment.

FAQs of Corn Grinder Machine:

Q: How do I operate the Corn Grinder Machine safely and efficiently?

A: To operate the Corn Grinder Machine, ensure it is connected to the appropriate power supply (220V or 440V). Follow the user manual for start-up, gradually feed corn into the hopper, and adjust settings as needed. Always wear safety gear and keep hands away from moving parts for optimal and safe performance.Q: What are the environmental benefits of this corn grinder?

A: The machine is designed to be eco-friendly, featuring lower energy consumption and reduced noise. These characteristics support sustainability efforts by decreasing electricity usage and minimizing auditory disturbances in the workplace.Q: When is the best time to schedule maintenance for the grinder?

A: Routine maintenance should be conducted as outlined in the user guide, usually every few months or according to usage intensity. Scheduled downtime helps prevent wear and tear, ensuring the machine operates efficiently throughout its one-year warranty period and beyond.Q: Where can I purchase the Corn Grinder Machine in India?

A: This machine is available through authorized distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers across India. Please contact your nearest dealer or inquire with the supplier directly for assistance.Q: What is the typical process of using this corn grinder for industrial purposes?

A: Begin by connecting the machine to a compatible power source and conduct a safety check. Load corn into the hopper and select the desired settings. The high-performance motor will process corn quickly and efficiently, discharging ground corn for further processing or packaging.Q: How does the warranty coverage work for this machine?

A: A one-year warranty is provided against any manufacturing defects, ensuring peace of mind and reliable after-sales support. Claims can be made through the dealer or supplier should any issue arise within the warranty period.Q: What are the main benefits of choosing this specific corn grinder over others?

A: This grinder stands out due to its broad capacity range, high efficiency, energy-saving design, eco-friendly operation, and low noise output. These attributes collectively enhance productivity while maintaining operational costs and supporting sustainable practices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding, crushing and Pulverizing Machine Category

Pulverizer For Mineral Grinding

Price 18000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Automatic : Yes

Material : Stainless Steel

Herb Grinder

Price 56000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Automatic : Yes

Material : Stainless Steel

Auto Suction Hammer Mill

Price Range 18500.00 - 125000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 415 Volt (v)

Automatic : Yes

Material : Stainless Steel

Sugar Grinding Machine

Price Range 18500.00 - 125000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 415 Volt (v)

Automatic : Yes

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free