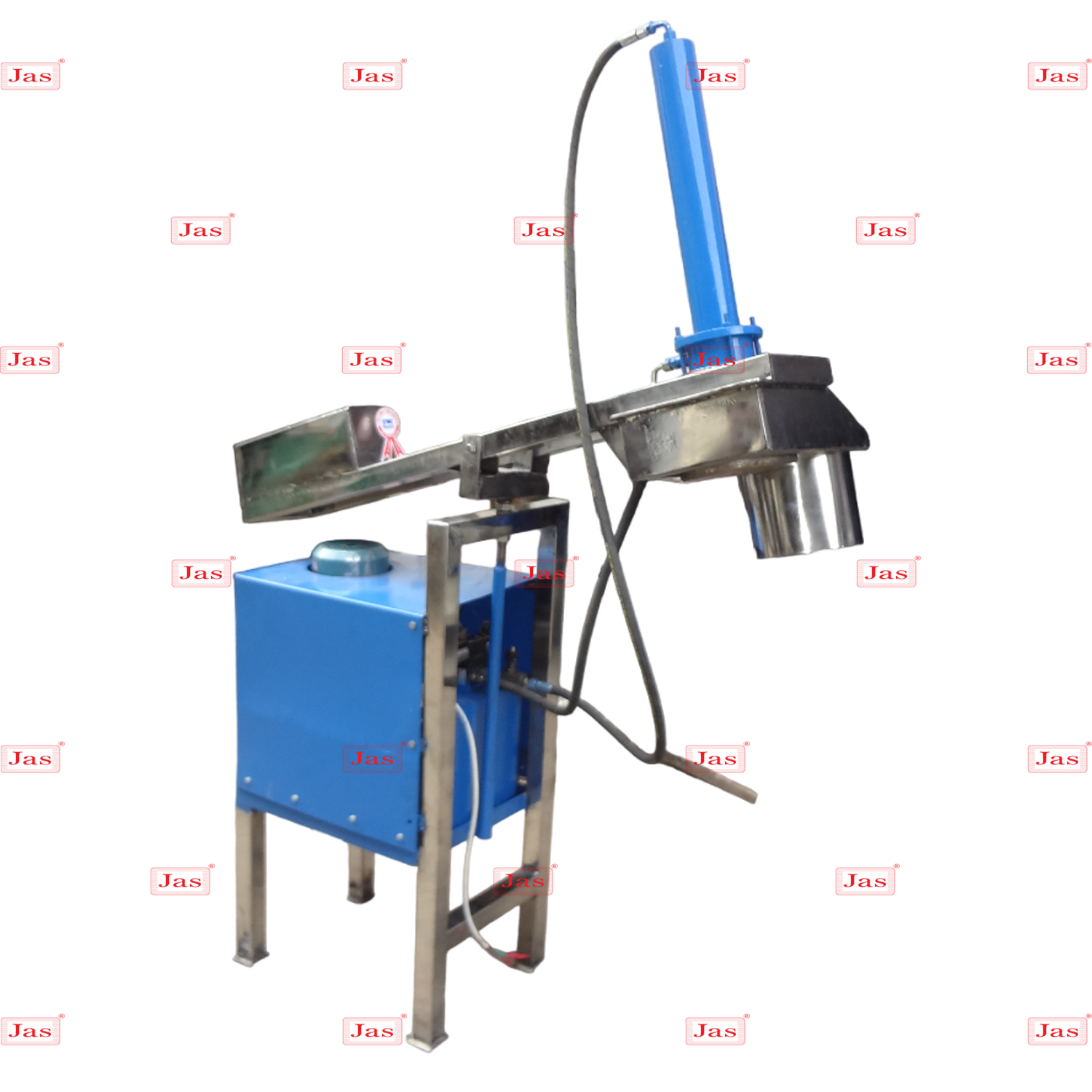

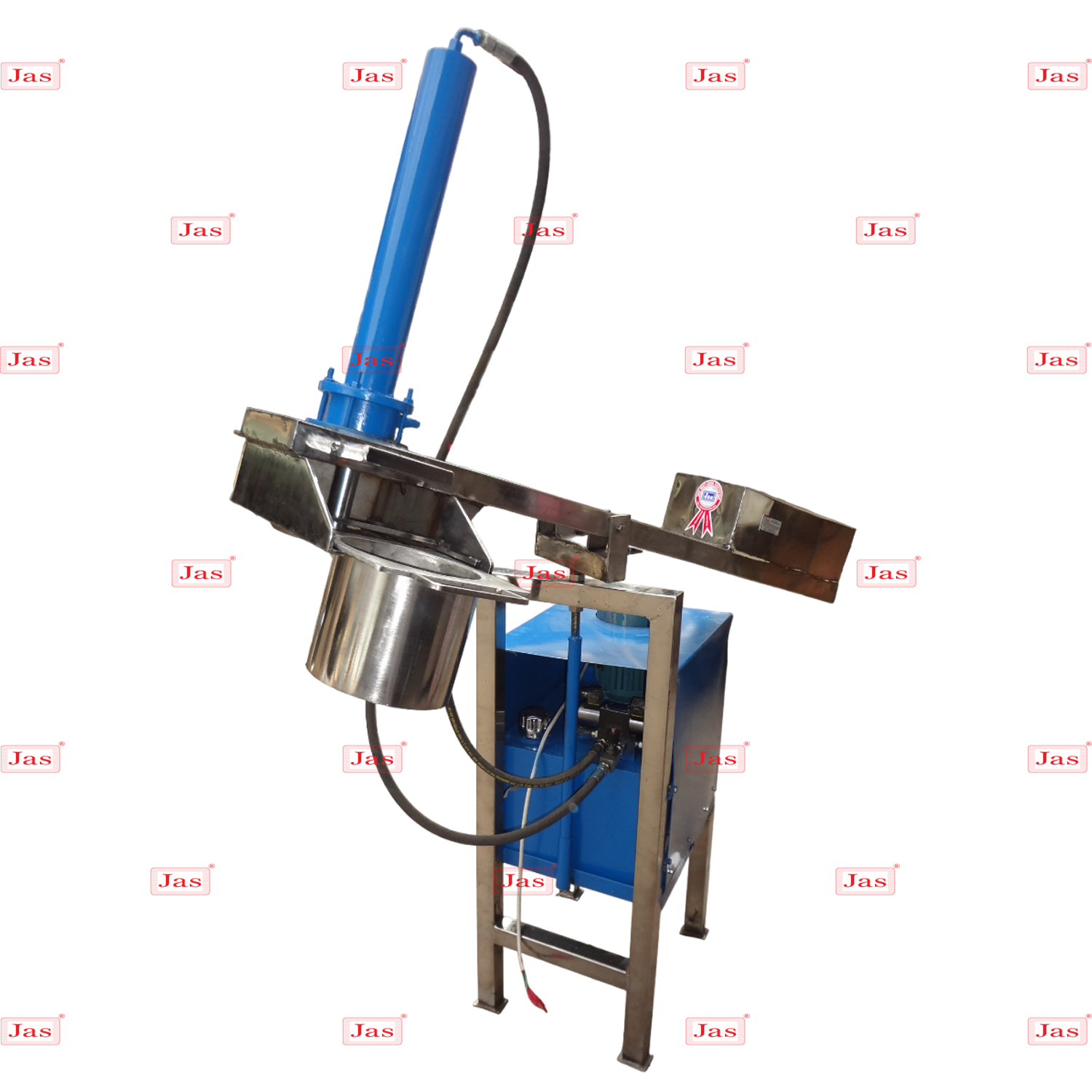

Hydraulic Namkeen Machine

Price 85000 INR/ Unit

Hydraulic Namkeen Machine Specification

- Capacity

- 45-100 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Hydraulic Namkeen Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Hydraulic Namkeen Machine

-

Hydraulic System: The hydraulic system in the machine provides the necessary force to press or extrude the namkeen mixture. This system uses hydraulic pressure to ensure consistent and precise production.

-

Extrusion and Shaping: The machine often includes an extrusion mechanism that shapes the namkeen mixture into various forms, such as sticks, rings, or pellets. This process involves forcing the mixture through molds or dies.

-

Heating: Many hydraulic namkeen machines come with built-in heating elements or compartments for frying the namkeen. This ensures that the namkeen is cooked evenly and achieves the desired crispiness.

-

Adjustable Settings: The machine usually has adjustable settings for temperature, pressure, and speed, allowing for customization based on the specific recipe and desired texture of the namkeen.

-

Material: Typically, the machine is made from high-quality stainless steel to ensure durability and ease of cleaning.

-

Capacity: Hydraulic namkeen machines vary in size and capacity, from small models suitable for small-scale production to larger models designed for industrial-scale operations.

How It Works

-

Preparation: The namkeen mixture, which includes ingredients like flour, spices, and other flavorings, is prepared and loaded into the machine.

-

Extrusion: The hydraulic system applies pressure to the mixture, forcing it through molds or dies to shape it into the desired form.

-

Cooking: Depending on the machine, the shaped namkeen may be cooked through frying or baking within the machine.

-

Cooling and Packaging: After cooking, the namkeen is cooled and then packaged for distribution.

Benefits

- Consistency: Hydraulic pressure ensures that each batch of namkeen has a uniform texture and shape.

- Efficiency: The machine speeds up production compared to manual methods, making it suitable for larger quantities.

- Customizability: Adjustable settings allow for different shapes, sizes, and textures of namkeen.

Eco-Friendly Snack Production

This machine supports sustainable operations by reducing energy consumption and noise pollution. Its eco-friendly design makes it an excellent choice for businesses aiming to lower their environmental impact while maintaining productivity.

Efficient & Automatic Operation

The hydraulic system provides consistent force and speed, while the automated functions streamline namkeen production. This translates into higher output with minimal manual intervention, reducing labor costs and human error.

Compact Structure for Versatile Placement

With its space-saving design, the machine easily fits into shops, factories, or kitchens of various sizes. This versatility is ideal for retailers and manufacturers looking to optimize their workspace without sacrificing capacity.

FAQs of Hydraulic Namkeen Machine:

Q: How does the Hydraulic Namkeen Machine ensure eco-friendly and efficient operation?

A: The machine utilizes a hydraulic system that consumes less energy and produces minimal noise, ensuring both environmental friendliness and operational efficiency. Its design also reduces waste and optimizes the production process.Q: What is the production capacity range of this machine, and what types of businesses benefit most?

A: The machine has a capacity of 45-100 kg/hr, making it suitable for small to large-scale businesses such as distributors, manufacturers, exporters, retailers, wholesalers, and traders in the snack industry across India.Q: When is the ideal time to use the Hydraulic Namkeen Machine in snack manufacturing?

A: The hydraulic machine is ideal for daily, high-volume namkeen production, especially during peak seasons, festivals, or promotional sales when demand for snacks is high and consistent quality output is required.Q: Where can this machine be installed, given its compact structure?

A: Thanks to its compact design, the machine can be installed in small kitchens, large manufacturing units, retail shops, and factory floors, making it adaptable for various operation sizes.Q: What is the process for operating the machine and ensuring automatic production?

A: After initial setup and ingredient loading, the machine automatically manages the production cycle, including mixing, shaping, and cutting, reducing manual intervention and optimizing output.Q: How does the automatic feature benefit manufacturers and suppliers?

A: The automatic operation enhances productivity and consistency by minimizing manual labor, cutting costs, and ensuring uniform quality. This is especially beneficial for manufacturers and suppliers handling large orders.Q: What are the usage and voltage specifications for the Hydraulic Namkeen Machine?

A: The machine runs efficiently on either 230 or 440 volts, suitable for standard commercial electrical systems in India. It is designed to handle continuous usage while maintaining safety and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Namkeen Making Machine Category

Boondi making machine

Price 22000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 2.5 kW

Capacity : 100150 kg/hr

Automatic : Yes

Namkeen Farsan Mixer Machines

Price Range 45000.00 - 135000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 1 to 2 Horsepower (HP)

Capacity : 50 to 100 Kg/hr

Automatic : No

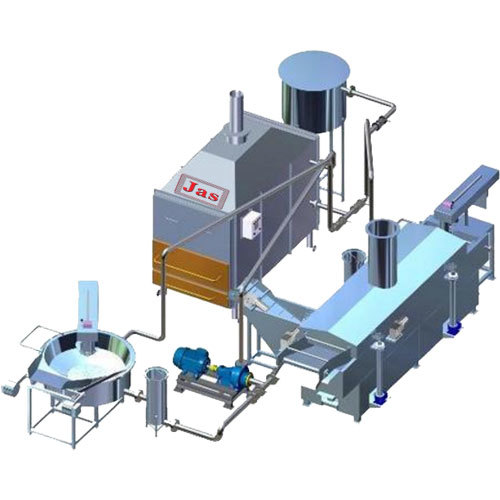

Potato Chips Frying Equipment

Price 350000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 6.515 Horsepower (HP)

Capacity : 50 to 500 Kg/hr

Automatic : Yes

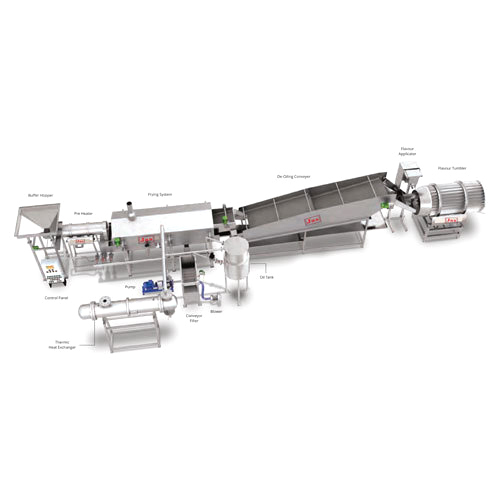

Snacks Making Line

Price 350000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 520 Horsepower (HP)

Capacity : 100 TO 300 Kg/hr

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free