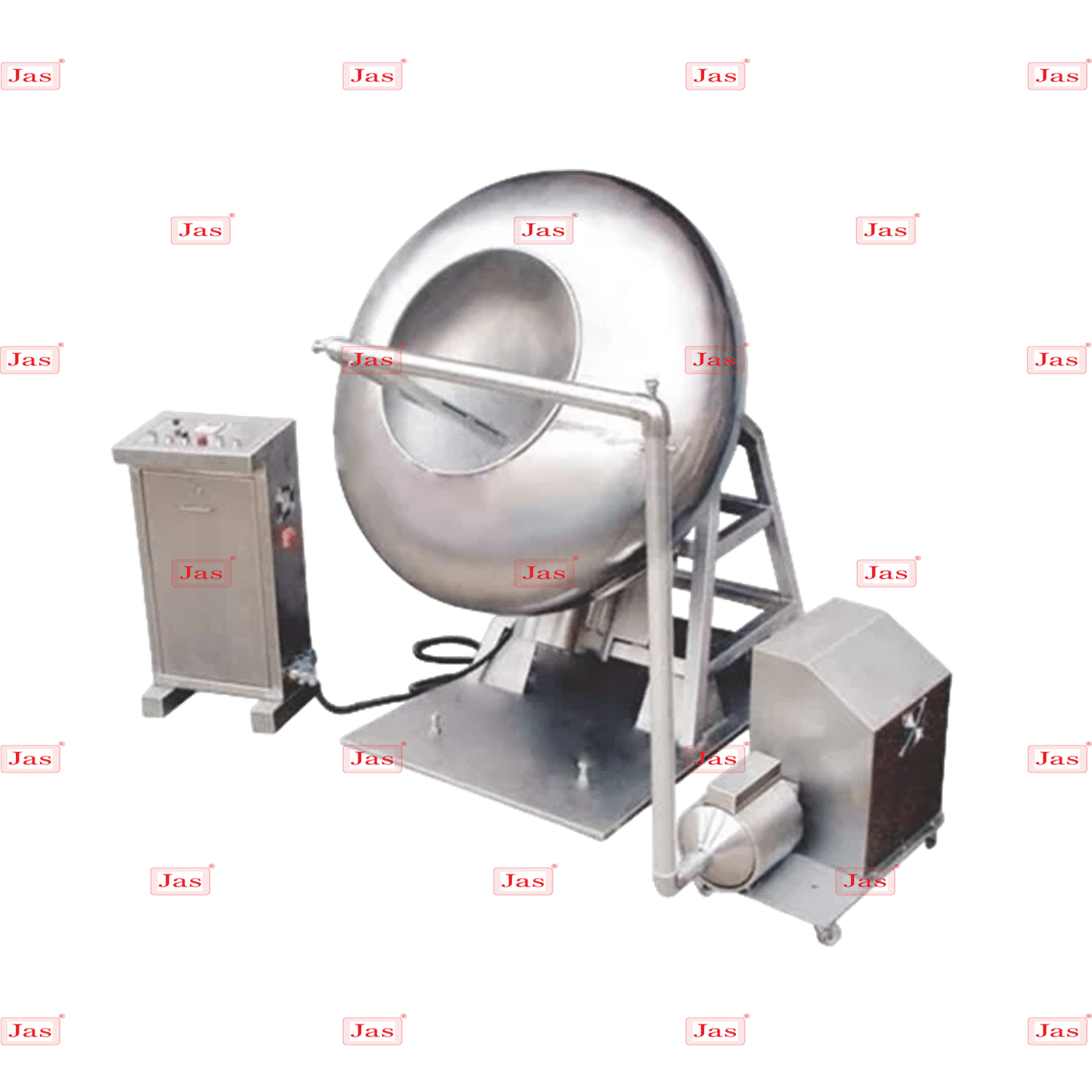

Laboratory Coating Pan

Price 170000 INR/ Unit

Laboratory Coating Pan Specification

- Capacity

- 12-520 Ltr/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Laboratory Coating Pan Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Laboratory Coating Pan

Functions:

-

Coating Application: It applies a uniform layer of coating material to the surface of particles. This coating can serve various purposes, such as protecting the core material, controlling the release of active ingredients, or enhancing appearance.

-

Mixing: It ensures that the coating material is evenly distributed over the particles by rotating and tumbling them.

-

Drying: In some setups, the coating pan can also incorporate heating elements to help dry the coating material quickly.

Components:

-

Pan: The rotating drum or pan where the particles and coating material are placed.

-

Drive Mechanism: Powers the rotation of the pan. This can be a motor or other mechanical system.

-

Coating Spray System: Delivers the coating material (often a liquid) onto the particles. This system might include pumps, nozzles, and other components.

-

Airflow System: Used for drying and cooling, this might include fans or blowers.

-

Control System: Manages the speed of rotation, coating application, and other parameters.

Advanced Coating Technology for Laboratories

This laboratory coating pan integrates state-of-the-art technology to deliver consistent and uniform coating of tablets and other materials. Its high operational efficiency and automatic controls minimize manual intervention, promoting safety and reliability in laboratory settings. With capacity options up to 520 liters per hour, it caters to diverse production needs while maintaining eco-friendly attributes.

Eco-Friendly and Energy-Saving Features

Engineered with sustainability in mind, the coating pan utilizes mechanisms that deliver low noise operation and significantly reduced energy consumption. The compact design ensures optimal use of laboratory space, while its high efficiency streamlines the coating process. These features collectively help laboratories meet environmental standards and cost-saving goals without compromising performance.

FAQs of Laboratory Coating Pan:

Q: How does the laboratory coating pan process operate automatically?

A: The pan uses an integrated automatic control system that regulates temperature, rotation speed, and coating material application, ensuring consistent results with minimal operator intervention.Q: What are the main benefits of the compact structure in laboratory environments?

A: The compact structure saves valuable bench space, allows easier installation in confined labs, and simplifies maintenance without sacrificing capacity or performance.Q: When should laboratories consider using this coating pan for production?

A: It is best suited for facilities requiring efficient, high-volume coating from 12 to 520 liters per hour, especially in pharmaceutical, food, and chemical labs seeking consistent quality and energy savings.Q: Where can this laboratory coating pan be sourced in India?

A: The pan is available nationwide through distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers, ensuring easy access for laboratories across India.Q: What is the environmental impact of using this laboratory coating pan?

A: Its eco-friendly operation, low noise output, and lower energy consumption help labs reduce their environmental footprint, contributing to green initiatives and regulatory compliance.Q: How does high efficiency enhance laboratory productivity?

A: High efficiency ensures faster cycle times, uniform coating, and reduced wastage, which streamlines laboratory workflows and boosts overall productivity.Q: What steps are involved in the coating process using this pan?

A: Tablets or materials are loaded into the pan, where they are tumbled and coated with solutions as the pan rotates. The automatic system controls temperature and spray application for precision results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Peanut Butter Making Machine

Price 85.0 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Voltage : 230/440 Volt (v)

Automatic : Yes

Capacity : 501000 Kg/hr

Sieving Machine

Price 49500 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Voltage : 230/440 Volt (v)

Automatic : No

Puff Extruder Machine

Price 250000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Lower Energy Consumption, ECO Friendly, Low Noice, High Efficiency, Compact Structure

Voltage : 110 to 440 Volt (v)

Automatic : Yes

Capacity : 100Kg p hour Kg/hr

Onion Cutting Machine

Price 4500 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Voltage : 230/440 Volt (v)

Automatic : Yes

Capacity : 10150 Kg/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free