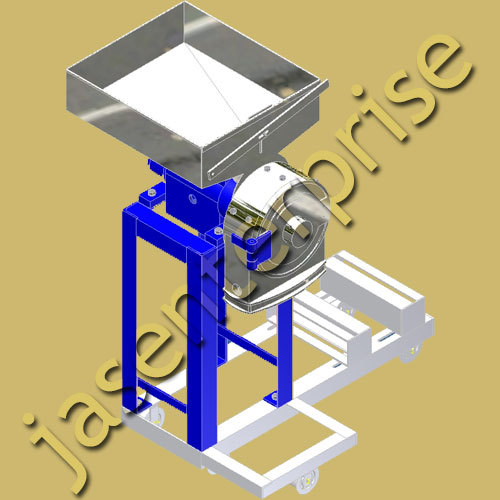

Mini Pulverizer

Mini Pulverizer Specification

- Material

- Stainless Steel

- Capacity

- 30-35 Kg/hr

- Weight (kg)

- 65 Kilograms (kg)

- Automatic

- Yes

- Power

- 1500 Watt (w)

- Voltage

- 110 to 415 Volt (v)

- Dimension (L*W*H)

- 36 X 50 X 93 Centimeter (cm)

- Color

- Blue

Mini Pulverizer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- Week

- Main Domestic Market

- Pondicherry, Manipur, Andaman and Nicobar Islands, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Gujarat, , South India, North India, East India, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttar Pradesh, Punjab, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, Himachal Pradesh, All India

About Mini Pulverizer

We have gained huge gratitude in the industry by engaging ourselves in manufacturing and exporting sturdily built Mini Pulverizer. To provide best quality products, we assure to use one of the best quality raw materials and other components that are obtained from authentic vendors. Our offered pulverizer is manufactured into various grades and models that clients can avail as per their needs. We deliver this Mini Pulverizer with the help of our reliable carriage & freight personnel within the time specified.

This pulverizer is highly reckoned for:

- Sturdy construction

- Optimum functionality

- Perfect finish

- Safe operation

Other details:

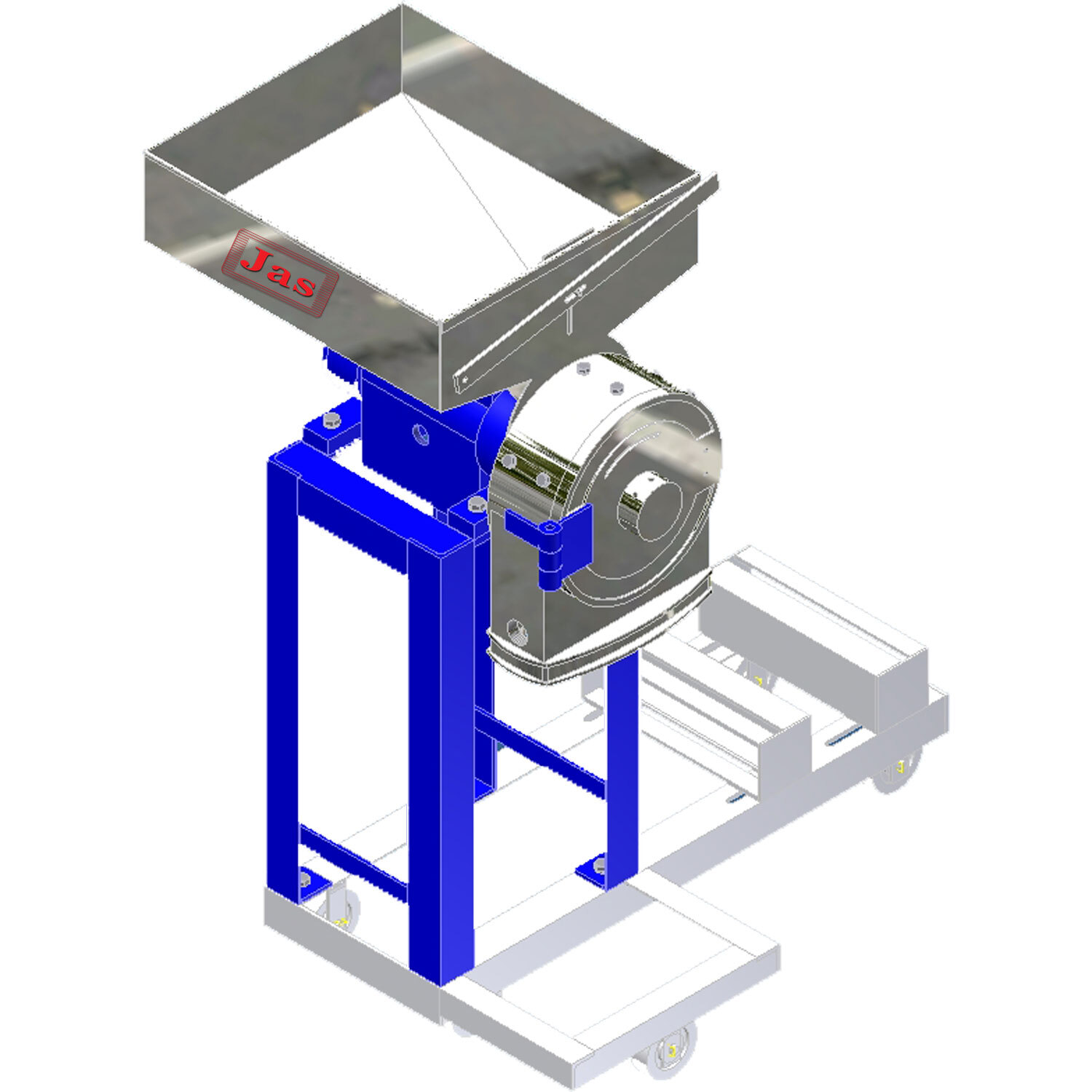

Key Features of mini pulverizers:

- Unique and Reliable Design

- The Miniseries Pulverizers are highly effective as well as nonstop continuous pulverizing process.

- Compact size

- Dust free operation

- Ideal for dry crushing

- Increased production leading to faster return on the investments

- Hardened and fully machined beaters thus less wear and Terre.

- Single pieces grinding chamber no separate joints of fabrication for out late.

- Motor pulley

- One number cotton balloon.

- Easy movable trolley with adjustable rail for motor

- five numbers perforated Round holes Screen

- Suitable totally enclosed fan cooled single or three phase Sq. cage motor as per IS: 325 or 996 (Special power can be accommodated): 110/220/380/415 Volts, 50/60 Hz , 1/3 Phase

- Suitable miniature circuit breaker as per IS: 8828 with 3 meter cable and 3 pin top as per IS: 1293

- V Belts

Product details

|

Phase |

Single Phase |

|

Material |

Stainless Steel |

|

Power |

2 HP. |

|

Voltage |

380V |

|

Machine Capacity |

10 to 250 Kgs./ Hour |

|

Usage/Application |

Commercial |

|

Automatic Grade |

Automatic,Manual,Semi-Automatic |

High-Efficiency Pulverizing Technology

The Mini Pulverizer delivers outstanding grinding speed and consistency, capable of processing up to 35 kilograms per hour. Its automatic mechanism and stainless steel construction ensure both hygiene and durability, making it a trusted choice for diverse commercial requirements. The power-efficient design reduces operational costs without compromising on output quality.

Flexible Applications Across Industries

Engineered to operate across a wide voltage range, the Mini Pulverizer integrates seamlessly into various settings, including food production, chemical processing, and agricultural use. Its compact dimensions allow for easy installation in retail, wholesale, and large-scale manufacturing environments throughout India.

FAQs of Mini Pulverizer:

Q: How does the Mini Pulverizer operate automatically?

A: The Mini Pulverizer operates with a fully automatic mechanism, meaning it requires minimal manual intervention. Simply load the material, and the efficient motor system, powered at 1500 watts, takes care of the grinding process.Q: What materials can be processed using this pulverizer?

A: This pulverizer, crafted from stainless steel, is suitable for grinding a range of materials including grains, spices, herbs, and certain chemicals, making it ideal for various industrial and commercial applications.Q: When should the Mini Pulverizer be used in production?

A: It is best to use the Mini Pulverizer when you need consistent, high-speed grinding for batches up to 35 kg per hour, ensuring optimal efficiency in food processing, pharmaceuticals, or agricultural industries.Q: Where can the Mini Pulverizer be installed and used effectively?

A: Thanks to its compact design (36 x 50 x 93 cm), the machine can be installed in small workshops, large factories, or retail outlets across India, accommodating a variety of workspace sizes and layouts.Q: What is the process for operating and maintaining this pulverizer?

A: Start by loading the raw materials into the input chamber, set your desired grinding specifications, and turn on the machine. For maintenance, regularly clean the stainless steel surfaces and inspect motors and blades for wear to prolong lifespan.Q: How does using the Mini Pulverizer benefit businesses?

A: Using this machine increases productivity by automating the grinding process, providing consistent material output, and reducing operational overheads, making it a valuable asset for distributors, manufacturers, and retailers alike.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding, crushing and Pulverizing Machine Category

Cattle Feed Grinder

Price 15000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 415 V

Automatic : Other, Semiautomatic

Capacity : 800 1000 kg/hr

Feature : Other, Heavy Duty, High Productivity

Coriander Grinder Machine

Price 56000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220/440 Volt (v)

Automatic : No

Capacity : 30160 Kg/hr

Feature : High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Maize Grinding Hammer Mill

Price 15000.00-650000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 20 to 2200 Kg/hr

Auto Suction Hammer Mill

Minimum Order Quantity : 1 Unit

Voltage : 110 to 415 Volt (v)

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS