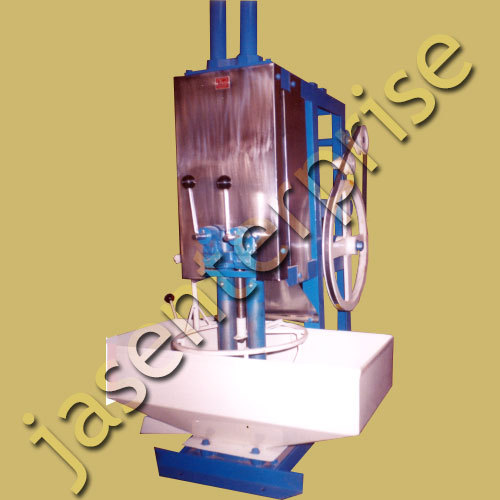

Steel Flour Mill

Price 29000 INR/ Unit

Steel Flour Mill Specification

- Capacity

- 30-170 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Steel Flour Mill Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Steel Flour Mill

-

Cleaning and Conditioning: The grains are first cleaned to remove impurities like dirt and stones. Sometimes, the grains are conditioned by adding moisture to make them easier to mill.

-

Milling: The conditioned grains are fed through a series of steel rollers. These rollers are set at precise distances to crush and break down the grains into smaller particles. The process is usually done in multiple stages, with the rollers getting progressively finer to achieve the desired flour consistency.

-

Separation: After milling, the flour is separated from the bran and germ using sifters or air classifiers. This step ensures that the flour has the right texture and quality for various baking needs.

-

Blending and Packaging: The final flour may be blended with other types of flour or additives to achieve specific qualities before being packaged for distribution.

Exceptional Performance

Our Steel Flour Mill delivers consistent grinding capabilities without excessive energy consumption, making it ideal for businesses seeking cost-effective, high-yield flour production. Whether you are scaling operations or supporting local demand, the high efficiency of this mill assures dependable output with minimal environmental impact.

Versatile Applications

Designed to cater to a broad range of users including manufacturers, traders, and suppliers, the automatic flour mill adapts to various operational requirements. Its robust build and low noise performance make it suitable for urban and rural settings, supporting Indias diverse agro-based industries.

FAQs of Steel Flour Mill:

Q: How does the automatic feature benefit the operation of the Steel Flour Mill?

A: The automatic functionality simplifies the milling process, reducing manual intervention and optimizing efficiency. This ensures consistent flour quality and improved safety during continuous operation.Q: What is the process for installing the Steel Flour Mill, and where can it be used?

A: Installation typically involves connecting to a 230/440 volt (v) power source and following the manufacturers setup guidelines. The mill can be installed in flour processing facilities, shops, or industrial environments throughout India.Q: When should businesses choose a Steel Flour Mill with a 30-170 kg/hr capacity?

A: This mill is suitable for operations requiring moderate to large flour production volumes. It is ideal for businesses seeking to process wheat or other grains efficiently, matching varying demand scales.Q: Where can I purchase the Steel Flour Mill in India?

A: The mill is available through multiple channels including distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers across India. Contact local partners for more information or to place an order.Q: What are the main usage benefits of this flour mill?

A: Users benefit from high efficiency, low noise, eco-friendly operation, and reduced energy consumption. These features contribute to lower operating costs and a more sustainable production process.Q: How does the mill support eco-friendly and low-noise operation?

A: It incorporates advanced engineering to minimize power consumption and operational noise, benefiting both the environment and workplace comfort.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding, crushing and Pulverizing Machine Category

Food Grinder

Price 56000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 30160 Kg/hr

Feature : High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Automatic : Yes

Wheat Grinding Machine

Price Range 18500.00 - 88000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Lower Energy Consumption, High Performance, ECO Friendly, Low Noise, High Efficiency

Automatic : Yes

Pulverizing Machine

Price 18000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 202200 Kg/hr

Feature : High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Automatic : Yes

Chilli Pounding Machine

Price Range 18500.00 - 125000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 3035 Kg/hr

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free