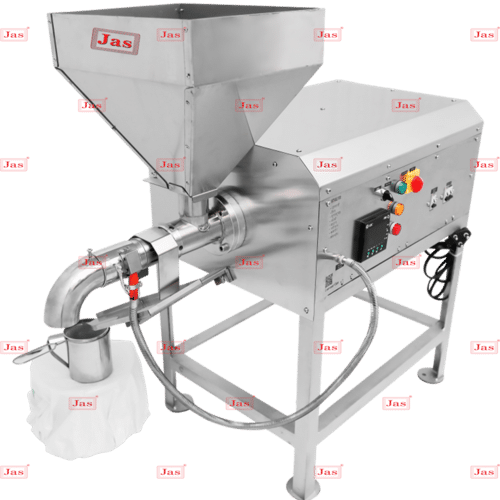

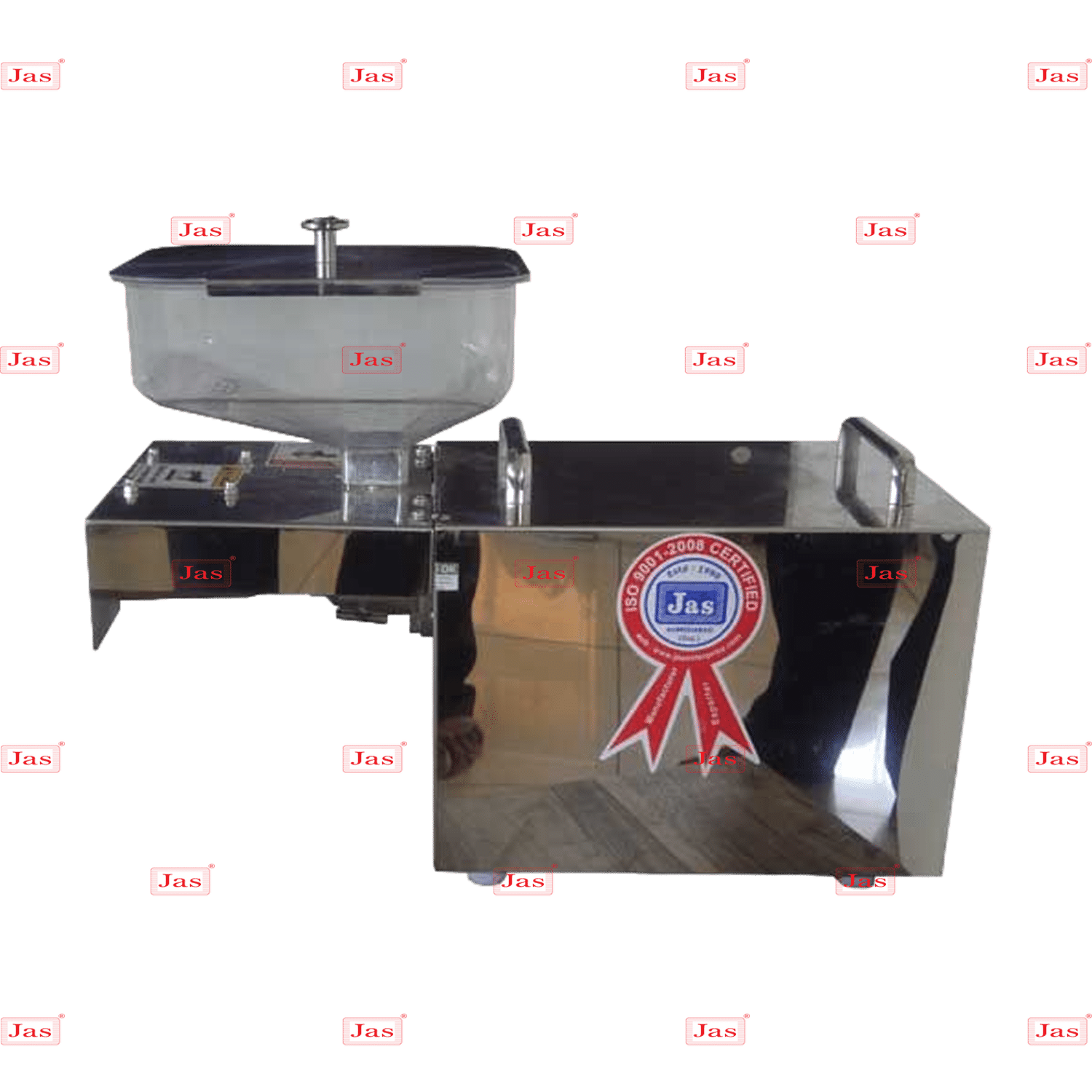

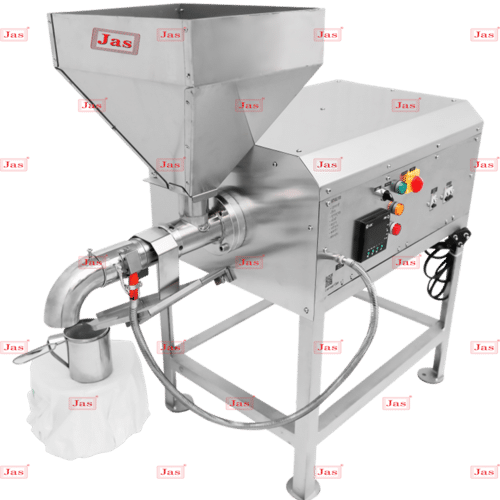

Vegetable Oil Extraction Machine

Price 16000 INR/ Unit

MOQ : 1 Unit

Vegetable Oil Extraction Machine Specification

- Power Source

- Electric

- Automation Grade

- Automatic

- General Use

- Industrial

- Material

- Stainless Steel

- Capacity

- 2-25 Kg/hr

- Computerized

- No

- Automatic

- Yes

- Installation Type

- Free Stand

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Color

- Sliver

- Warranty

- 1 Year

Vegetable Oil Extraction Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Vegetable Oil Extraction Machine

Types of Vegetable Oil Extraction Machines

-

Expeller Presses:

- Cold Press: Extracts oil without heating, preserving the nutritional quality and flavor of the oil.

- Hot Press: Uses heat to extract more oil and increase efficiency but may affect the oils quality.

-

Solvent Extractors:

- Utilizes solvents like hexane to dissolve and extract oil from the seeds or nuts. After extraction, the solvent is evaporated, leaving behind the oil.

-

Hydraulic Presses:

- Uses hydraulic pressure to squeeze oil from seeds. Typically used for smaller scale operations or high-quality, artisanal oils.

-

Screw Presses:

- Employs a screw mechanism to press oil from seeds. This is a common choice for larger scale operations due to its efficiency.

Key Components

- Feeder: Introduces the seeds into the machine.

- Crushing Chamber: Breaks down the seeds to prepare them for extraction.

- Pressing Chamber: Where the actual extraction takes place, using mechanical force or heat.

- Filter: Removes impurities and particulates from the extracted oil.

- Oil Cake Outlet: The byproduct of the extraction process, which can be used as animal feed or compost.

Efficient, Eco-Friendly Extraction

This vegetable oil extraction machine stands out for its environmentally conscious design. Low noise and low energy consumption combine with high efficiency, enabling continuous industrial use without excess waste or disturbance. Its eco-friendly operation can help businesses reduce their carbon footprint and comply with modern environmental standards.

Flexible and High-Capacity Operation

Capable of processing 2 to 25 kg of raw materials per hour, the machine appeals to both small-scale and larger industrial operations. Automation simplifies the extraction process, while the durable stainless steel build ensures longevity and hygiene, meeting diverse business requirements.

Simple Installation and Reliable Support

The machine features a free-standing structure for hassle-free setup in a variety of industrial settings. With a 1-year warranty and support from trusted Indian distributors and manufacturers, buyers can enjoy peace of mind and reliable service post-purchase.

FAQs of Vegetable Oil Extraction Machine:

Q: How does the automatic vegetable oil extraction machine operate?

A: The machine is fully automatic and relies on an electric power source (230/440 Volt) to efficiently extract oil from seeds or nuts. Its automation ensures consistent output with minimal human intervention, enhancing productivity in industrial settings.Q: What types of businesses can benefit from this extraction machine?

A: This machine is designed for a range of users, including distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers. It is ideal for businesses in India seeking efficient, eco-friendly, and high-output oil processing solutions.Q: When should I use the vegetable oil extraction machine?

A: You should use this machine when consistent, efficient, and large-scale oil extraction is needed. Its especially suited for continuous operations in environments where hygiene, energy efficiency, and reduced noise are important considerations.Q: Where can the machine be installed?

A: Thanks to its compact, free-standing structure, the machine can be placed in any industrial facility with adequate electric supply. Its stainless steel body and compact form make it suitable for diverse workspaces requiring ergonomic and efficient setups.Q: What is the process for extracting oil with this machine?

A: Simply load the desired quantity of seeds or nuts (up to 25 kg/hr), select the appropriate settings, and start the machine. It automatically handles the extraction with minimal supervision, delivering high-purity oil efficiently.Q: What are the main benefits of using this vegetable oil extraction machine?

A: The machine offers high efficiency, low noise, energy savings, and eco-friendly operation. Its durable stainless steel construction ensures long service life, while automatic controls streamline the extraction process, providing consistent results with reduced labor.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Oil Mill, Oil Extraction Machinery & Equipment Category

Oil Processing Machinery

Price 16000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 225 Kg/hr

Automatic : Yes

Computerized : No

Flex Seed Oil Extraction Machine

Price 20000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 25 Kg/Hour Kg/hr

Automatic : Yes

Computerized : No

Ayurvedic Seeds Oil Extraction Machine

Price Range 20000.00 - 130000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 2 to 20 Kg/hr

Automatic : Yes

Computerized : Yes

Flaxseed Oil Extraction Machine

Price Range 20000.00 - 130000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 2 to 20 Kg/hr

Automatic : Yes

Computerized : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free