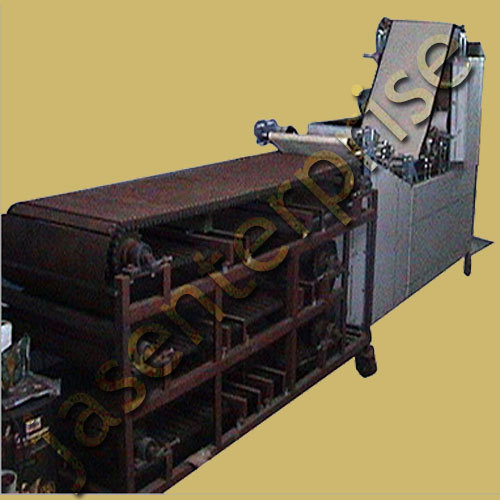

Roti Maker

Price 10000 INR/ Unit

MOQ : 1 , , Unit

Roti Maker Specification

- Material

- Stainless Steel, Aluminum

- Capacity

- 200-400 Chapati Kg/hr

- Computerized

- No

- Automatic

- No

- Voltage

- 440 Volt (v)

- Color

- White,Blue and Black

Roti Maker Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Months

- Main Domestic Market

- All India

About Roti Maker

Being a customer oriented organization, we are deeply engaged in offering a wide array of Manual Chapati Making Machine. Jas Enterprises Manual Chapati, tortilla roti maker are mostly known as "Chapati Maker" or "Roti Maker" but also sometimes known by the other names like Pani Puri Making Machine, Rice Papadi Machine, Bhakri Making Machine, Rice Bhakri Making Machine, Manual Rice Bhakri Making Machine, Manually Hand Pressing Pani Puri Making Machine, Chapati Making Machine, hand operated Chapati Making Machine, Manual Chapati Making Machine, JAS Chapati Making Machine, Thepla Making Machine, Manual Thepla Making Machine, Papad Making Machine, Papadi Making Machine or Manual Papadi Making Machine.Engineered for High Efficiency

This Roti Maker stands out thanks to its impressive 200-400 chapati per hour capacity, making it perfect for food service establishments looking to boost productivity. Crafted with premium stainless steel and aluminum, it ensures durability and longevity, while its non-automatic operation makes it user-friendly and easy to maintain.

Versatile Solutions for Businesses

Whether youre a distributor, retailer, or wholesaler, this Roti Maker can scale to meet your commercial requirements. Its powerful 440 Volt system ensures consistent performance, while the chic white, blue, and black color options allow it to fit seamlessly into various kitchen environments across India.

FAQs of Roti Maker:

Q: How do you operate the non-automatic roti maker?

A: To operate this non-automatic roti maker, simply prepare dough, manually feed dough balls into the press, and use the lever or handle to flatten and cook chapatis. Since its not computerized or automatic, operation involves direct user input, offering better control over texture and thickness.Q: What capacity does the roti maker handle per hour?

A: This roti maker can produce between 200 and 400 chapatis per hour, making it suitable for commercial establishments such as restaurants, hotels, and catering services that require consistent high-volume output.Q: Where is this roti maker commonly used in India?

A: The roti maker is popular in various commercial applications across India, including restaurants, hotels, industrial kitchens, catering companies, and institutional cafeterias that need efficient, bulk chapati production.Q: When should a business consider using this roti maker?

A: Businesses should consider this roti maker when they need to fulfill high-volume chapati requirements promptly and efficiently, especially in peak service hours or for large events, to streamline operations and save labor costs.Q: What materials are used in the construction, and why are they beneficial?

A: Manufactured with stainless steel and aluminum, this roti maker is rust-resistant, sturdy, and easy to clean, thus promoting food safety and ensuring longevity even with constant use in busy kitchens.Q: What is the process for cleaning and maintaining the roti maker?

A: After use, turn off the power supply and let the machine cool. Remove any leftover dough, and wipe the surfaces with a damp cloth. Regularly check for any buildup or residue, and ensure all components are dry before use to maintain hygiene and performance.Q: What are the key benefits of choosing this roti maker for your business?

A: Key benefits include high output capacity, durable metal construction, compatibility with standard 440 Volt power supplies, and adaptability for commercial environments. Its manual operation offers precision, while the range of colors adds flexibility for different kitchen aesthetics.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Chapati Making Machines Category

Dough Kneader

Price 6000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 5 to 50 Kg/hr

Automatic : Yes

Computerized : No

Material : Stainless Steel

Roti Chapati Machines

Price 50000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : >900 Kg/hr

Automatic : Yes

Computerized : No

Material : Stainless Steel, Aluminum

Phulka Roti Making Machine

Price 10000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 600 to 3000 Roti/Hr Pcs/min

Automatic : Yes

Computerized : Yes

Automatic Chapati Making Machines

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 3000.0 Kg/hr

Automatic : Yes

Computerized : No

Material : Stainless Steel, Aluminum

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free